This can be a fun project, welding sheet is actually quite enjoyable once you know some key fundamentals. Sheet metal is a flat, thin piece of metal which we can find in our daily use items such as cooking utensils or even the shining metals on your car. Starway teaches you how to weld sheet metal like a pro with the right tools This is a great skill to have, and it will be able you to make lots of stuff on your own

There are some tips and tricks that you need to be aware of before starting welding sheet metal. Before this, it is very important to make sure your metal surface was clean when you start welding. If there is any rust, oil residue, paint or grime you can remove this with a wire brush that may be adhering to its surface. Clean it — this will help the metal to stick and give you a good weld. A surface that is dirty or dusty will create a weaker weld and this results in possible issues later

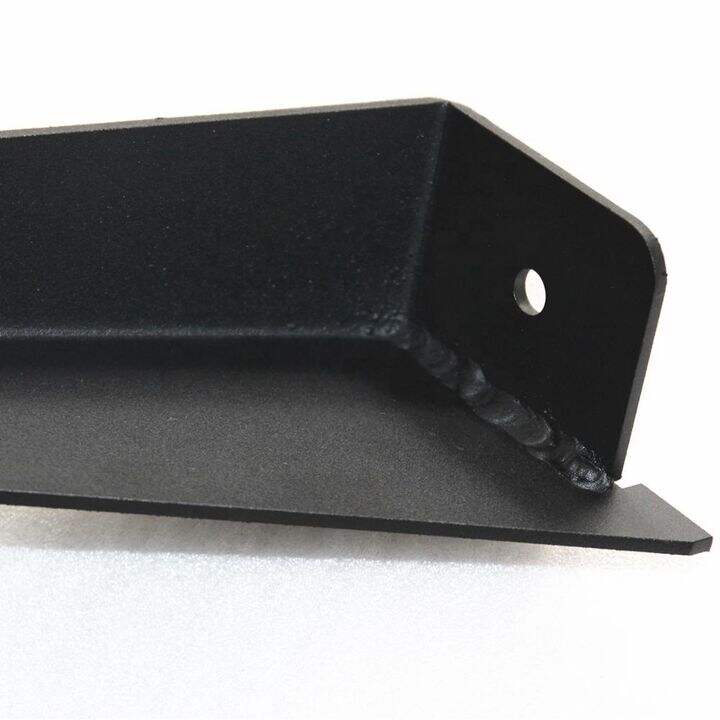

The following point you will wish to do is clamp both steel items with each other. Connecting secures to the components you're functioning on is constantly useful when attempting to some sheet steel. This is big since if the steel relocations, it will ruin your welds. And lastly regard welding constantly Sheet steel sheet hold really high warm for lengthy time periods. Allow the steel cool off in between welds, by doing this you will not curved the product. This will maintain you much more secure and assistance to arrange your work correctly

Comprehending the Fundamentals of Sheet Steel Previously sheet metal welding density is determined in evaluates. A evaluate is a number you check out when taking a look at the steel, and it acts in this esoteric way: The reduce the variety of the recommendation -the thicker your item of steel. 14- and 16-gauge sheet steel are rather different, however what is the distinction in between them? As you select the appropriate welding technique, particularly keep in mind which product density can be bonded how. Keep in mind that sheet steel is slim and quickly warped or thawed, so you need to ensure it obtains like.

Each type of sheet metal is best suited to a different welding technique. An example of this is TIG, short for Tungsten Inert Gas welding. If you need to work on thinner and more intricate sheet metal then TIG welding is the way ahead. This is good for metal stitching and reduces the heat input to avoid HAZ damages. In comparison, The MIG (‑ Metal Inert Gas) welding is the most performing TIG setup and allowing you to work with thicker sheet metals. This method is much faster, and it involves using a wire feed to bind the two pieces of metal together. MIG welding is just as beginner-friendly, perhaps even more so.

Going straight in when you encounter problems sheet metal welding because there are some mistakes that everybody is going to make. Not using the right welding technique for a job is actually once of the most common mistakes one can make. If you use the wrong method, your weld might not be strong enough or have to much warping of the sheet metal with possibility even that this will melt. One mistake to avoid is applying too much heat. Just one example is ski-boxes made of sheet metal: applying a too-clever workaround to this, the team in which I worked had problems with it ending up melted or bent…because they applied so much heat on that damn thing. This is why it becomes very much crucial for you to use the right heat setting suiting the thickness of metal that you are working on.

To weld sheet metal, you have to prepare properly and practice the right techniques with well-planned tools. TIG welder are ideal for working with thin sheet metal, and MIGs can handle thicker pieces. You also need a solid set of clamps to hold every piece of metal together while you are welding it. Be sure to clean the metal surface with a wire brush and some acetone before you begin. This will help eliminate any unnecessary residue.

We well-known capacity create new ideas quickly welding sheet metal. In thriving relationship clients rapid adaptation changes design product during development phase, offering expert insights refine sketches speed up process. We assisted clients make thousands products utilizing 15-years experience custom-made metal processing. clients enjoyed advantages competition because innovative products created. commitment excellence sure clients receive optimal solutions, allow to navigate complex landscape confidence.

order welding sheet metal system highly efficient, scientifically-designed tool ensures speedy processing each customer order. streamlined order management platform, customers are to submit orders quickly monitor status real-time. We a high priority precision execution orders, we remain constant contact communicate customers throughout entire production process. lets respond swiftly any requests design modifications improvements. Whatever size your order approach every order care, ensuring prompt processing high-quality outcomes. dedication quality demonstrates determination exceed customer expectations every interaction.

service team welding sheet metal pre-sales group is proficient English well as business communication as well engineers skilled processing product technology. Through collaboration between sales technical staff, guarantee efficient communication our customers, while understanding requirements. This enable offer customers convenient one-stop customized processing solutions. understand specificity each project, our team spare effort ensure smooth completion your project, which results a win-win partnership.

provide open transparent service, are always looking long-term partnership our customers. We strongly believe honesty is foundation of collaboration clients. welding sheet metal negotiating deals offer fair prices professional guidance. We remain constant contact customers during entire production process so are aware. Are transparent about manufacturing process communicating updates fixing any issues as quickly possible. Customers invited give feedback anytime. developed long-lasting, steady relationships large number clients thanks transparent open communication.