Anyone who wants to craft projects out of metal or need maintenance from time-to-time will do well for themselves if they can weld. Welding is a unique ability in which you apply heat to fuse metal portions collectively. The following article will serve as a guide for everything you need to know on how to weld sheet metal, which indeed is a kind of thinner metals employed in myriad domains like cars or airplanes and even buildings.

The Starway sheet metal welding is an art in itself and, as with any kind of instruction you may find that watching videos can be great way to pick up on a new skill. The most important precaution you should know: HEAT; do not weld too hot. When metal heats up too high, it can plastic-, warp-, or worst of all–melt completely and ruin your project. If you don't want to have this type of challenge, we recommend using a lower heat setting and go slowly.

This Maintenance Tip is what to do before you even start welding and that first step is clean the metal really well. Welders compete with robots by relying on sheet metal that can be oily, painted or rusty — anything to give a processor an advantage. You can use a mild or special cleaner designed for this purpose, or you sand paper. This will make it easier for you to eliminate any grime or surface treatments that may hinder your ability to create a quality weld.

Writing exclusively for the website, they listed their top 5 tips on what welders should do to ensure strong and aesthetically appealing welds when working with thin metal: An example of this is TIG welding. Controlled Flaming: This is a method of using small torch flames. This technique is perfect for thin Starway sheet metal work as it keeps the heat transfer to a minimum which in return stops the piece of material from twisting or bending out of shape.

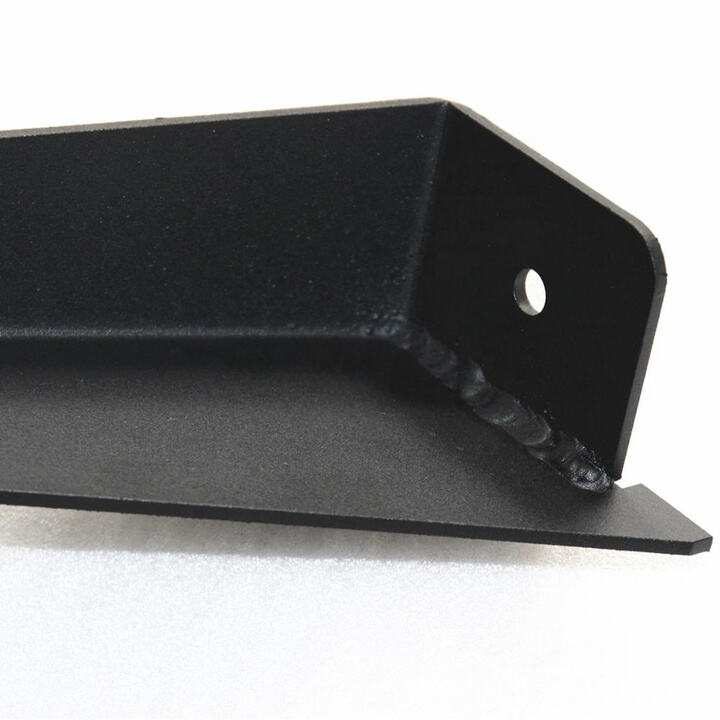

You will also have to fill with filler material A piece of this seemingly magical metal melts to become a liquid that quickly flows into the space between the two sheets you are trying weld together. This helps them adhere and amalgamate with each other. Different types of Starway sheet metal and welding may require different fillers and picks a right filler material is essential for safer welding.

In order to produce clean and sound welds on thin sheet metal, you should employ the tools that allow you to get your work accomplished in a safe manner. A welding helmet is a necessary piece of kit. This will shield your face and eyes from the bright light and any sparks that can come out of welding. Also required will be a welding gun or torch and it is the primary equipment you may use in performing the actual weld.

Like a good welding gun, there are many other fabrication tools that make it possible for you to create the best welds on sheet metal. Wire brush is one such tool. Before welding, a wire brush cleans up the metal. Be sure to choose a wire brush for steel sheet welding only as you want any contamination on the wires of the wheel, there are others that may damage or contaminate your working surface.

Welding sheet renowned for ability develop new ideas quickly efficiently. Based extensive communication clients rapid adaptation design changes throughout development phase, offering most knowledgeable advice refine drawings expedite process. We helped clients develop thousands new products utilizing 15 years expertise custom metal processing. clients enjoyed edge in market a result our innovative products have created. commitment quality makes sure that clients get most effective solutions helps navigate competitive landscape confidence.

team service professionals includes pre-sales team proficient English business communication, as well Welding sheet adept product processing technology. Through collaboration between sales technical personnel, we able communicate effectively customers thorough understanding needs. We offer customers flexible, personalized processing solutions all-inclusive. team committed ensure that project running smoothly.

Welding sheet order system functions using scientific approach, ensures quick processing tracking each order made customers. Through streamlined ordering platform, customers to submit orders quickly check their status real-time. We insist precise processing orders keep open dialogue clients during entire manufacturing process swiftly addressing design modifications requests upgrades. Whatever size your order approach every order meticulous attention, ensuring prompt processing quality results. dedication excellence underlines dedication exceed customer expectations every interaction.

Welding sheet open transparent services, always seeking long-term business cooperation customers. Integrity cornerstone business relationships. provide expert guidance fair pricing prior closing deals. In course production keep constant contact customers, ensuring they're informed developments. Additionally, are transparent manufacturing process, sharing updates addressing issues swiftly. Customers invited give feedback at time. Thanks transparent open approach, have forged solid long-term relationships increasing numbers customers.