Sheet metal fabrication is the process of forming, cutting, and assembling metal sheets into various shapes and structures. It involves several techniques such as cutting, bending, and welding,surface treatment to create finished products from sheet metal materials. Sheet metal, typically made from materials like steel, aluminum, or copper, is widely used in various industries for manufacturing parts and components of machines, vehicles, appliances, and more.

Starway's online sheet metal fabrication services offer a comprehensive and efficient solution for producing parts based on 3D CAD files or engineering drawings. Starway provide a variety of materials, including stainless steel,aluminum, brass, steel, and stainless steel, and cover multiple fabrication processes such as stamping, cutting, bending, and welding. Our services also include assembly, such as installing PEM inserts, design packaging drawings and packaging services. Starwaty can accommodate both low-volume prototypes and volume production, offering competitive custom pricing for sheet metal fabrication. Starway is committed to bringing your idea to life.

Starway are proud of the core advantages that make the customers’ job easier, faster and more saving.

Dedicated service teams will be established for each project. (Pre-sales Team+ Pre-sales Engineers. )

1.Design Support: Offers 3D modeling, optimization, and prototyping.

2.Material Selection: Provides various material options and customization.

3.Fabrication Processes: Includes laser cutting, stamping, bending, and welding.

4.Assembly: Offers insert installation, riveting, and full assembly.

5.Surface Treatment: Provides painting, plating, and polishing services.

6.Quality Inspection: Ensures compliance with dimensional and functional tests.

7.Packaging and Logistics: Ensures safe packaging and timely delivery.

8.After-Sales Service: Offers technical support and quality tracking.

Rapid new product development:3 days prototype manufacturing

From the initiation meeting and confirmation of drawings to the first piece inspection, mid-term quality reports, and final product inspection, every step efficient execution. 1.Offer order reports at least twice a week

2.offer SOP operation manuals for batch orders

3.Comprehensive quality inspection reports

Obtain An Instant Quote by uploading a 3D CAD file (including STEP, STP, SLDPRT, DXF, IPT, PRT, or SAT formats) through our Instant Quoting Engine.

Sheet metal is cut into the desired shape and size using various methods including shearing, laser cutting, plasma cutting, or water jet cutting. Precision cutting is essential to ensure accurate dimensions and smooth edges.

The sheet metal is bent into specific angles and shapes using press brakes or other bending machines. This process requires precise control of force and angle to achieve the desired bend without causing deformation or cracking.

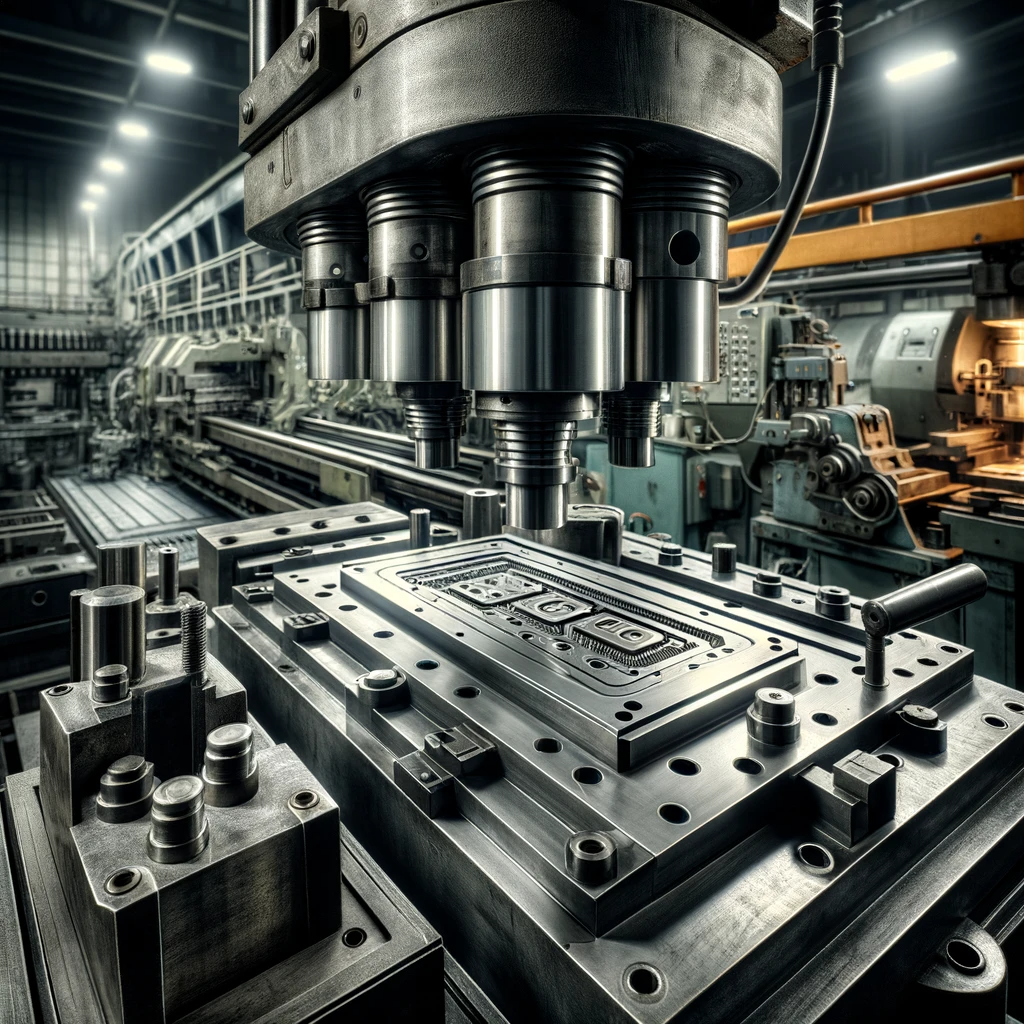

Additional forming processes such as rolling, punching, or stamping may be used to create complex shapes, contours, or features on the sheet metal.

Welding is used to join multiple pieces of sheet metal together. Common welding techniques include spot welding, MIG welding, TIG welding, and seam welding. Welded joints must be strong and durable to withstand the intended application.

After fabrication, the sheet metal may undergo surface treatments such as painting, powder coating, or plating to enhance its appearance and protect it from corrosion.

The fabricated components are assembled together to create the final product. This may involve fastening, riveting, or welding the components together.

| Material Thickness | Typical Tolerance |

| Up to 0.5 mm | ± 0.05 mm |

| 0.5 mm-2.0 mm | ±0.1 mm |

| 2.0 mm -5.0 mm | ± 0.15 mm |

| 5.0 mm-10.0 mm | ± 0.2 mm |

| 10.0 mm and above | ± 0.3 mm |

| Tolerances | |

| Forming and Bending: | +/- 0.4 mm |

| Bend to hole or feature: | +/- 0.2 mm |

| Linear dimensions excluding locations to bend | +/- 0.1 mm |

| Diameters with inserts | +/- 0.06 mm |

| Angularity | +/- 2 degrees |

| Surface roughness | +/- 3.2 micrometers |

| Countersink Tolerances | |

| Machined countersink major diameter | +/- 0.254 mm |

| Machined countersink minor diameter | 2/3 thickness |

| Formed countersink major diameter | +/- 0.381 mm |

| Formed countersink minor diameter | +/- 0.381 mm |

| Name | Materials | Color | Texture | Thickness |

| Anodizing | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. | A thin layer: 5-20 μm Hard anodic oxide film: 60-200 μm |

| Bead Blasting | Aluminum, Brass, Stainless Steel, Steel | None | Matte | 0.3mm-6mm |

| Powder Coating | Aluminum, Brass, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss | 5052 Aluminum 0.063"-0.500"6061 Aluminum 0.063"-0.500"7075 Aluminum 0.125"-0.250" Mild Steel 0.048"-0.500" 4130 Chromoly stee 0.050"-0.250" Stainless Steel 0.048"-0.500" |

| Electroplating | Aluminum, Brass, Stainless Steel, Steel | Varies | Smooth, glossy finish | 30-500 μin |

| Polishing | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy | N/A |

| Brushing | Aluminum, Brass, Stainless Steel, Steel | Varies | Satin | N/A |

| Silkscreen Printing | Aluminum, Brass, Stainless Steel, Steel | N/A | N/A | 1 μm |

| Passivation | Stainless Steel | None | Unchanged | 5μm-25μm |

Known for its good formability and strength, commonly used in manufacturing automotive parts, machinery components, and furniture.

Recognized for its corrosion resistance and excellent mechanical properties, suitable for producing kitchenware, medical equipment, and architectural components.

Lightweight with good thermal conductivity, often used in manufacturing aerospace components, automotive body panels, and electronic product enclosures.

Steel coated with a layer of zinc for corrosion resistance, commonly used in outdoor equipment, pipelines, and structural construction.

Known for its excellent electrical and thermal conductivity, commonly used in manufacturing electronic components, communication equipment, and decorative items.

Steel with specific chemical compositions and mechanical properties, suitable for producing high-strength parts and wear-resistant components.

Improving the smoothness and appearance of the metal surface through grinding and polishing techniques.

Including electroplating, galvanizing, chromium plating, etc., depositing another metal or alloy onto the metal surface to enhance its properties or appearance.

Applying protective or decorative coatings using spray painting techniques.

Changing the structure and properties of the metal by heating and cooling, such as quenching, tempering, etc.

Using high-pressure blasting to remove oxide layers and impurities from the metal surface, improving surface roughness.