Plastic Injection Molding: A Great Way to Make Stuff.

Have you been fed up with toys breaking after only an uses being few? Want to make fully sure your kitchen utensils last for years? look no other further than Starway plastic injection molding. This process allows for the development of strong, durable, and safe plastic items that may be used in a variety of ways. We’ll take a closer check the advantages of plastic injection molding and exactly how it really is found in manufacturing to produce these products we rely on every day.

One of the primary advantages of plastic injection molding is its capacity to make high-quality, uniform parts. When using injection molding, each right part is the same as the next, making sure everything works given that it should. Additionally, Starway plastic injection parts can be produced quickly and efficiently in large volumes, that makes it a cost-effective option manufacturers. Another advantage of plastic injection molding could be the selection of materials which you can use. From flexible plastics to more rigid compounds can develop a range of products and services with different properties.

Recent innovations in plastic injection molding technology are making the process a lot more cost-effective and efficient. With Starway plastic molding advancements in software and robotics, manufacturers can now design much molds more complex and precise than previously. Also, many manufacturers are actually using 3D printing to produce customized molds, further improving the efficiency and speed regarding the method.

When it comes to safety, plastic injection molding is among the safest techniques to produce plastic products. Since the procedure takes place in a closed method there is a reduced danger of for workers. Additionally, the materials used in injection molding are non-toxic and many are recyclable, making it a manufacturers option environmentally-friendly.

Plastic injection molding is employed in a wide number of and products. Toys, kitchen utensils, medical equipment, and automotive parts are only a few forms of the numerous items that could be created using injection molding. Since Starway injection molding parts can be created and quickly cost-effectively, manufacturers are able to quickly and efficiently produce the merchandise consumers require.

system managing orders efficient tool is scientifically designed guarantees prompt processing every order customers. system managing orders permits customers easily submit orders track status real-time. place high priority precise processing orders we keep constant line communicate clients throughout manufacturing process. lets us respond swiftly requests design modifications enhancements. Every order treated same level attention, making sure completed quickly delivered plastic injection molding quality. commitment excellence underscores commitment exceeding customers' expectations every interaction.

provide transparent open solutions, always seeking long-term business cooperation customers. We strongly believe honesty cornerstone relationships clients. provide expert advice fair pricing prior making agreements. We in constant communication our clients throughout manufacturing process make sure they kept informed. We also transparent manufacturing process. communicate updates address issues quickly. welcome suggestions feedback our customers any time. have developed long-lasting, steady relationships a large amount customers plastic injection molding our transparent open communication.

service team composed team pre-sales staff are fluent English, engineers experience processing technology. We sure both technical sales personnel work together plastic injection molding communicate effectively understanding requirements customers. offer clients efficient, custom-designed processing solutions that all-inclusive. We aware individuality every project, team make effort ensure smooth finalization project thus, achieving win-win cooperation.

plastic injection molding renowned for ability develop new ideas quickly efficiently. Based extensive communication clients rapid adaptation design changes throughout development phase, offering most knowledgeable advice refine drawings expedite process. We helped clients develop thousands new products utilizing 15 years expertise custom metal processing. clients enjoyed edge in market a result our innovative products have created. commitment quality makes sure that clients get most effective solutions helps navigate competitive landscape confidence.

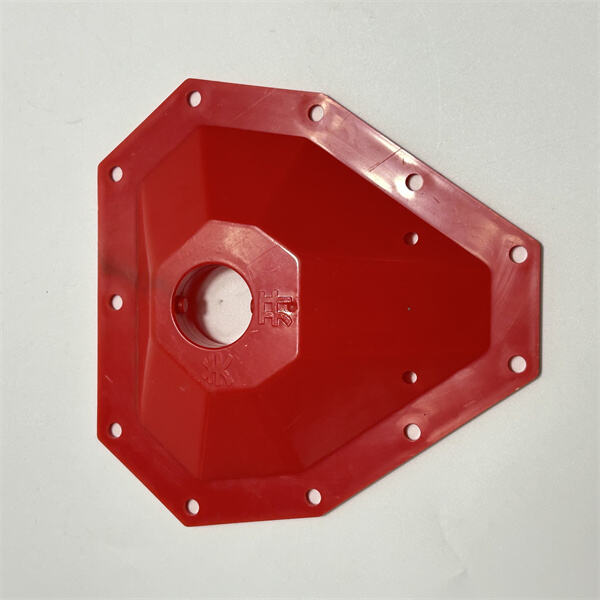

The process of plastic injection molding starts with a mold design. The Starway mold will be used to generate a cavity by which molten plastic is injected. Once the plastic has cooled and solidified, the mildew is opened additionally the finished product removed. injection-molded parts could be stated in an array of sizes and colors, with several finishes and this can be different textures. The flexibility from the process allows manufacturers to generate custom products which meet the certain needs of their customers.

In regards to plastic injection molding, service is key. Starway Manufacturers need to work closely making use of their customers to make sure that the goods being produced meet their exact specifications. From Starway material selection to mold design, there are numerous factors that want to be looked at when using injection molding. Working with a trusted partner who has got experience in injection molding is key to creating high-quality, efficient parts.

Quality is another important component consider when using plastic injection molding. Since each right part is the same as a greater, it’s necessary to make sure each part meets strict quality. Every step of the Starway method has to be carefully monitored to make sure that the final product is of the highest quality from the materials accustomed the finished product.