Computer Numerical Control (CNC) machining is a cutting-edge manufacturing technology that relies on computer control systems to operate machine tools and execute complex machining tasks. Unlike manual operation, CNC machines are guided by pre-programmed instructions (known as CNC code) that dictate the precise movements and actions required to shape raw materials into finished components. This advanced technology offers numerous advantages, including unparalleled precision, increased productivity, adaptability to evolving production demands, capability to handle intricate geometries, and consistency in quality across different batches of parts. As a result, CNC machining has become an indispensable aspect of modern manufacturing in industries such as aerospace, automotive, electronics, and medical devices.

Starway's online CNC machining service offers a comprehensive and efficient solution for manufacturing parts based on 3D CAD files or engineering drawings. We provide rapid prototyping, small-batch production, and high-volume manufacturing for various industries. Simply upload your files to receive instant pricing, lead times, and design-for-manufacturability feedback for your CNC parts.

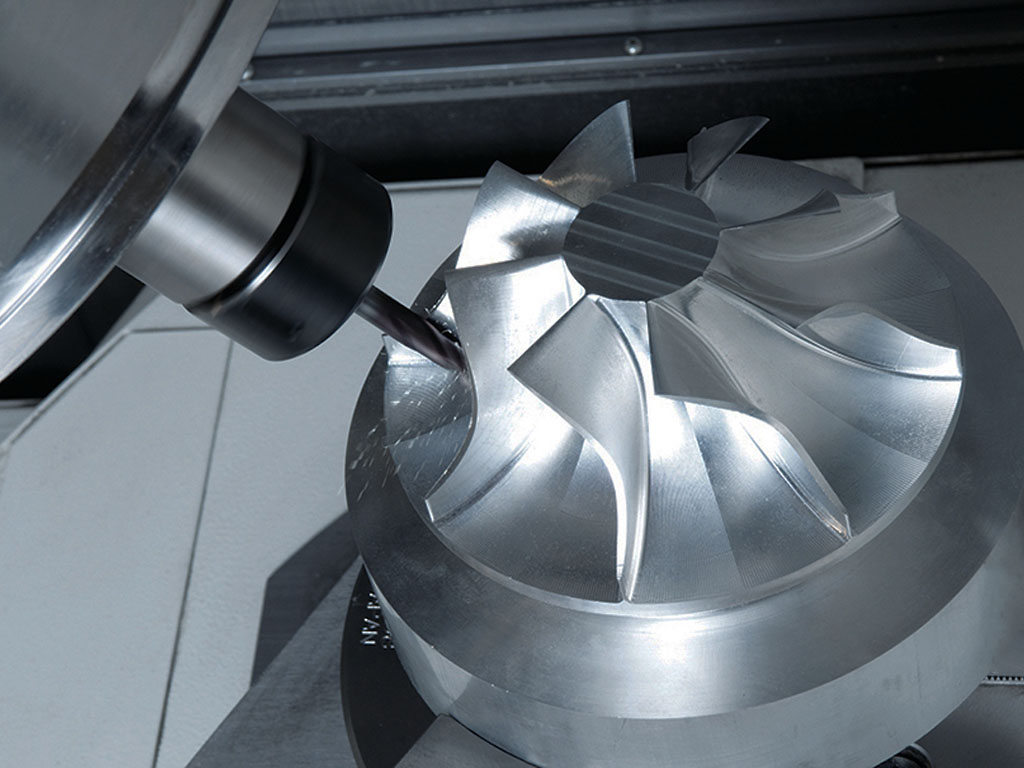

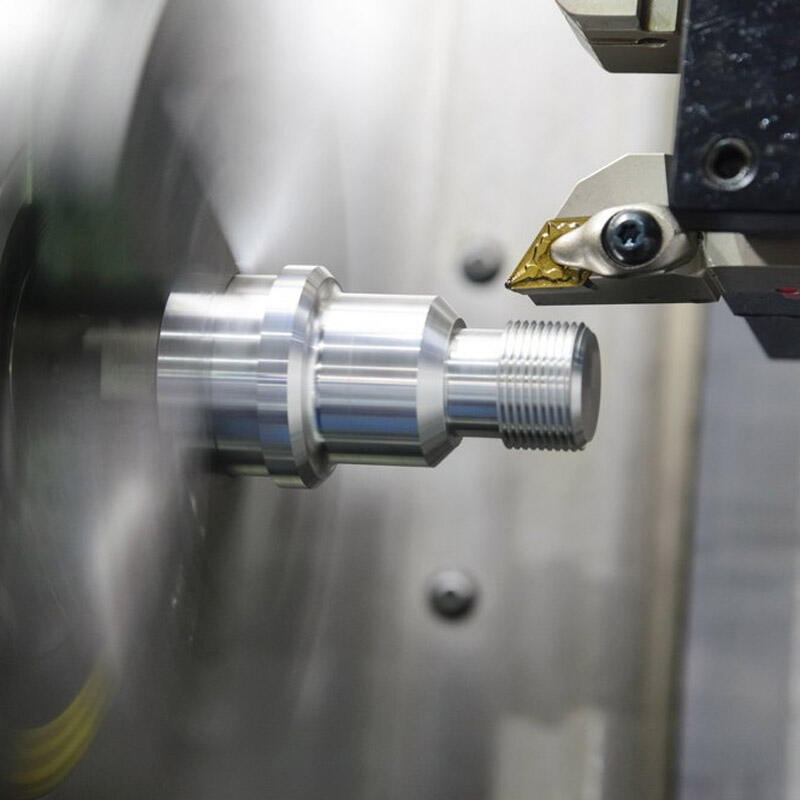

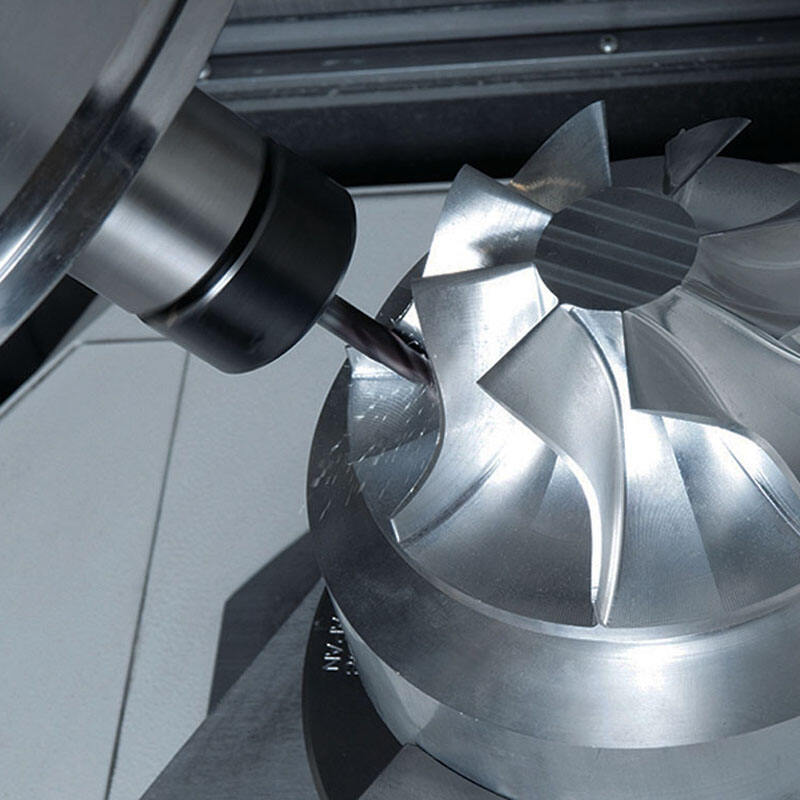

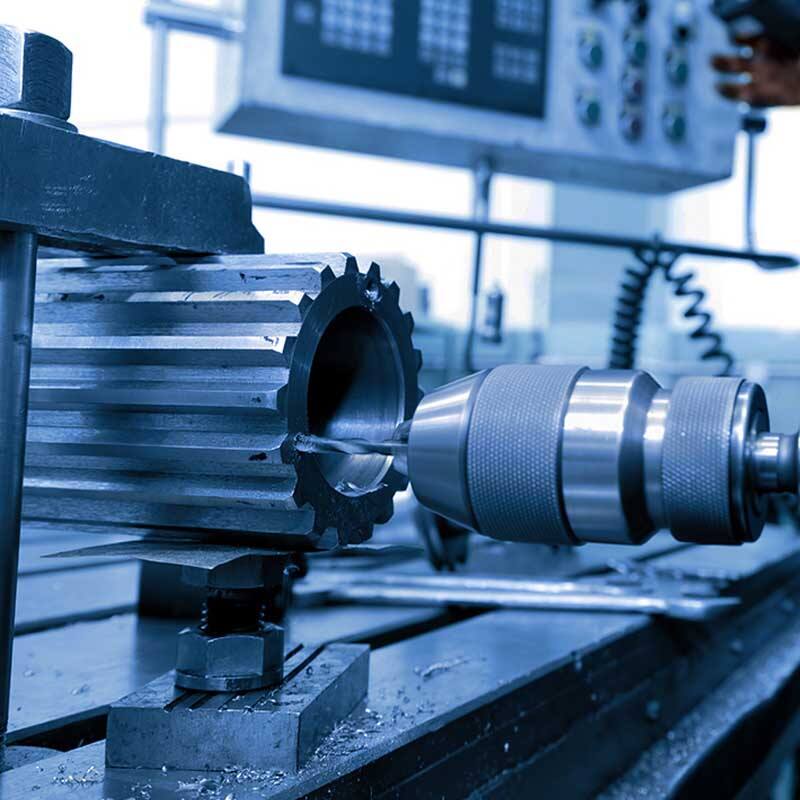

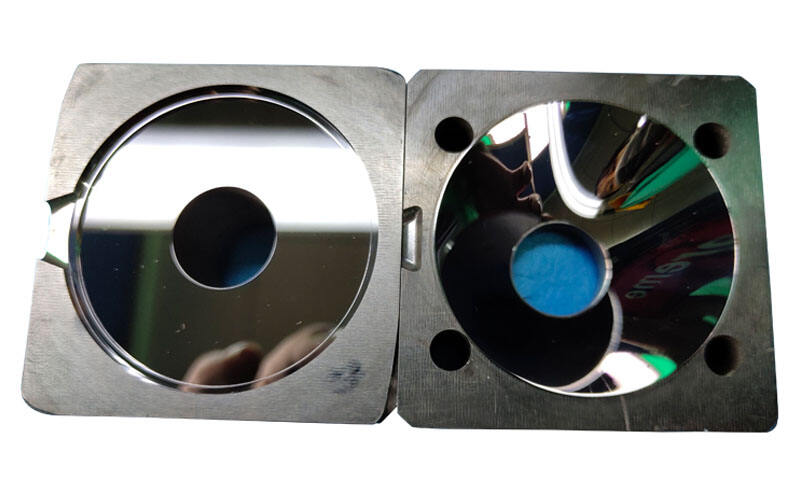

ISO-certified factory handle complex designs, including CNC turning of metal cylinders, conical parts, and pipes, as well as three-axis, four-axis, and five-axis CNC milling. With 11 years of industry experience and a team of skilled machinists, Starway can address any issues encountered during processing or drawing.

Additionally, Starway’s quality inspection team ensures the quality of your CNC machined parts through comprehensive quality control services, including ISO 9001 certification, inspections, hardware traceability, material certifications, and Certificates of Conformance (CoCs).

Starway s one-stop manufacturing service covers the entire production process from design to final product delivery, committed to providing comprehensive solutions.

Dedicated service teams will be established for each project. (Pre-sales Team+ Pre-sales Engineers. )

Starway's one-stop manufacturing service covers the entire production process from design to final product delivery, committed to providing comprehensive solutions.

1.Design Support: Offers 3D modeling, optimization, and prototyping.

2.Material Selection: Provides various material options and customization.

3.Fabrication Processes: Includes laser cutting, stamping, bending, and welding.

4.Assembly: Offers insert installation, riveting, and full assembly.

5.Surface Treatment: Provides painting, plating, and polishing services.

6.Quality Inspection: Ensures compliance with dimensional and functional tests.

7.Packaging and Logistics: Ensures safe packaging and timely delivery.

8.After-Sales Service: Offers technical support and quality tracking.

Rapid new product development:3 days prototype manufacturing

From the initiation meeting and confirmation of drawings to the first piece inspection, mid-term quality reports, and final product inspection, every step efficient execution. 1.Offer order reports at least twice a week

2.offer SOP operation manuals for batch orders

3.Comprehensive quality inspection reports

Obtain An Instant Quote by uploading a 3D CAD file (including STEP, STP, SLDPRT, DXF, IPT, PRT, or SAT formats) through our Instant Quoting Engine.

In turning, a lathe machine rotates a workpiece while a cutting tool removes material to create cylindrical shapes such as shafts, rods, and discs.

Milling involves rotating cutting tools with multiple teeth to remove material from a workpiece's surface, creating complex shapes, slots, and holes.

Drilling uses rotating drill bits to create cylindrical holes in a workpiece, often for fasteners or to accommodate other components.

Grinding uses the friction on the grinding wheel to remove excess scraps or burrs from the material and to achieve a precise surface finish on the workpiece.

Broaching utilizes a specialized tool with multiple teeth to remove material in a linear motion, creating keyways, splines, and other complex shapes.

Sawing includes the use of saw blades to cut workpieces, often used in products such as sheet metal or wood plastics through straight or curved cutting to complete the relevant product requirements.

Boring means the use of rotary cutting tools to enlarge an existing hole or to customize the exact inner diameter according to customer requirements.

It is processed by rotating a tap into a pre-drilled hole and tapping to produce an internal thread on the workpiece or in a custom form.

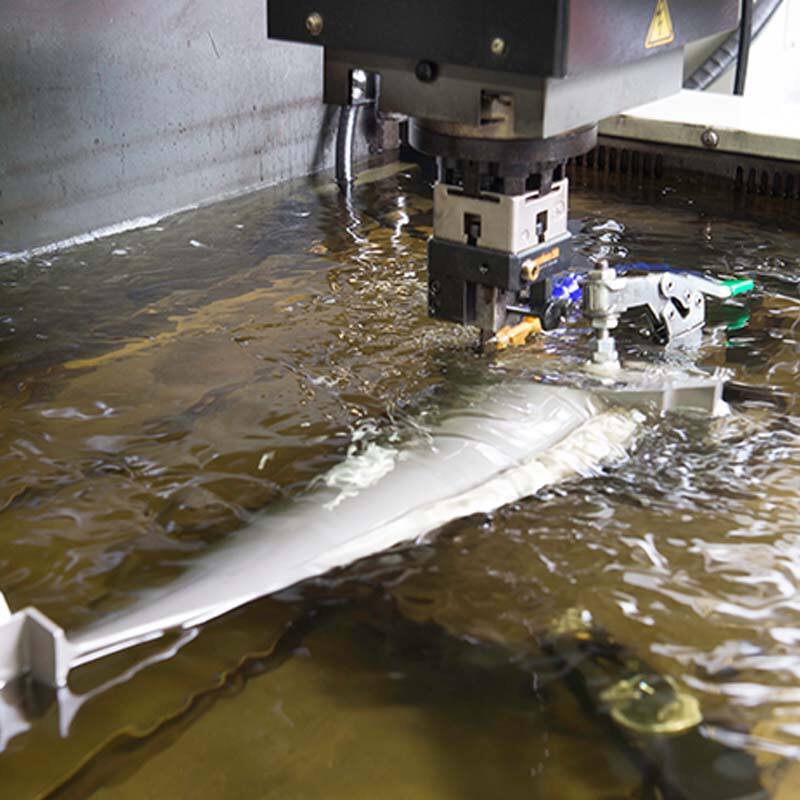

EDM uses electrical discharges to remove material from a workpiece, particularly for complex shapes or hardened materials.

| Size | Metric units | Imperial units |

| Max. part size for soft metals [1] & plastics | 2000 x 1500 x 200 mm 1500 x 800 x 500 mm | 78.7 x 59.0 x 7.8 in 59.0 x 31.4 x 27.5 in |

| Max. part for hard metals [2] | 1200 x 800 x 500 mm | 47.2 x 31.4 x 19.6 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

| Size | Metric units | Imperial units |

| Max. part size for all materials | 2000 x 1500 x 200 mm | 78.7 x 59.0 x 7.8 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

| Limits for nominal size | Plastics (2768- m) | Metals (2768- f) |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.3mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.5mm |

| Over 2000mm to 4000mm | ±2mm |

| Part size limitations | Metric units | Imperial units |

| Maximum part diameter | 431 mm | 17 in |

| Maximum part length | 990 mm | 39 in |

| Maximum swing over the carriage | 350 mm | 13.7 in |

| Maximum spindle through-hole | 40 mm | 1.5 in |

| Limits for nominal size | Plastics (2768- m) | Metals (2768- f) |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.3mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.5mm |

| Over 2000mm to 4000mm | ±2mm |

such as carbon steel, alloy steel, stainless steel, etc., commonly used for manufacturing mechanical parts and structural components.

known for its good strength and corrosion resistance, often used for manufacturing lightweight parts and structures.

known for its excellent conductivity and thermal conductivity, commonly used for manufacturing electrical components and heat-conducting parts.

an alloy of copper and zinc, known for its good machinability and corrosion resistance, commonly used for manufacturing valves, pipes, and other components.

such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), etc., commonly used for manufacturing plastic parts and housings.

known for its good wear resistance and compression strength, commonly used for manufacturing mechanical parts and bases.

Improving the smoothness and appearance of the metal surface through grinding and polishing techniques.

Including electroplating, galvanizing, chromium plating, etc., depositing another metal or alloy onto the metal surface to enhance its properties or appearance.

Applying protective or decorative coatings using spray painting techniques.

Applying protective or decorative coatings using spray painting techniques.

Using high-pressure blasting to remove oxide layers and impurities from the metal surface, improving surface roughness.