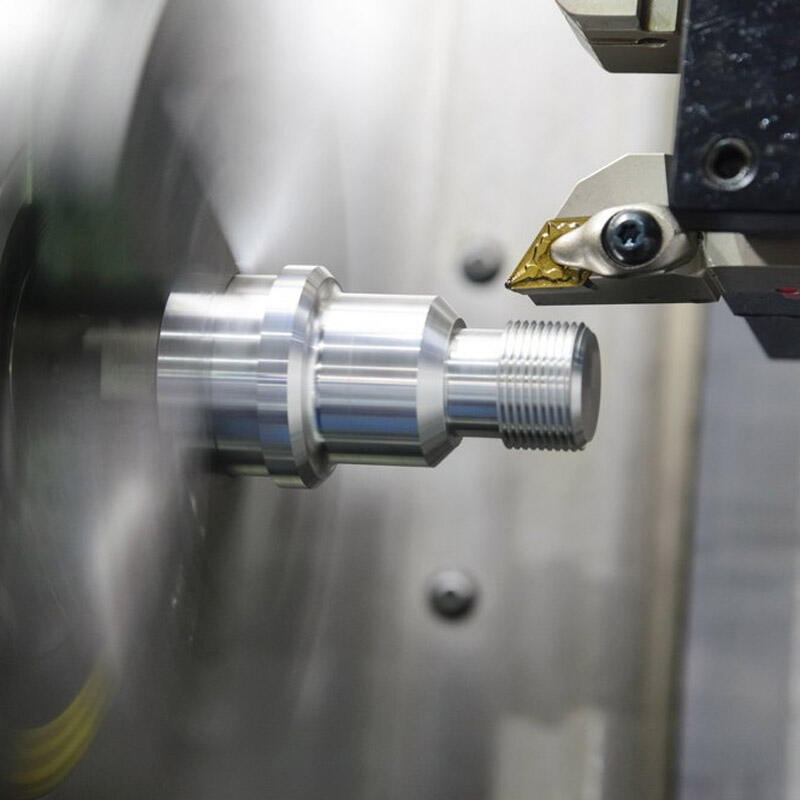

In turning, a lathe machine rotates a workpiece while a cutting tool removes material to create cylindrical shapes such as shafts, rods, and discs.

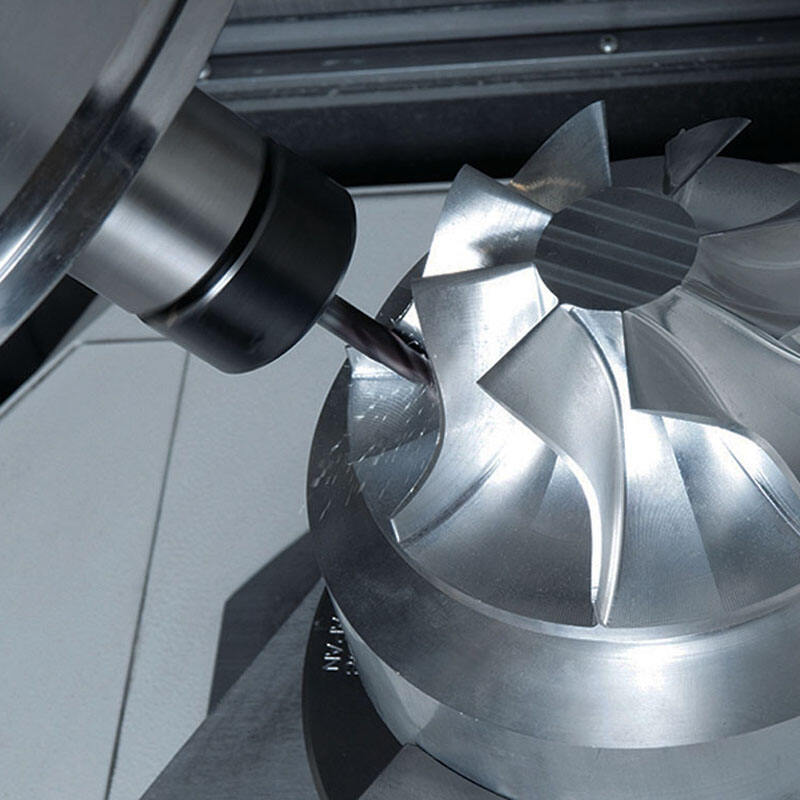

Milling involves rotating cutting tools with multiple teeth to remove material from a workpiece's surface, creating complex shapes, slots, and holes.

Drilling uses rotating drill bits to create cylindrical holes in a workpiece, often for fasteners or to accommodate other components.

Grinding employs abrasive wheels to remove material and achieve precise surface finishes on workpieces.

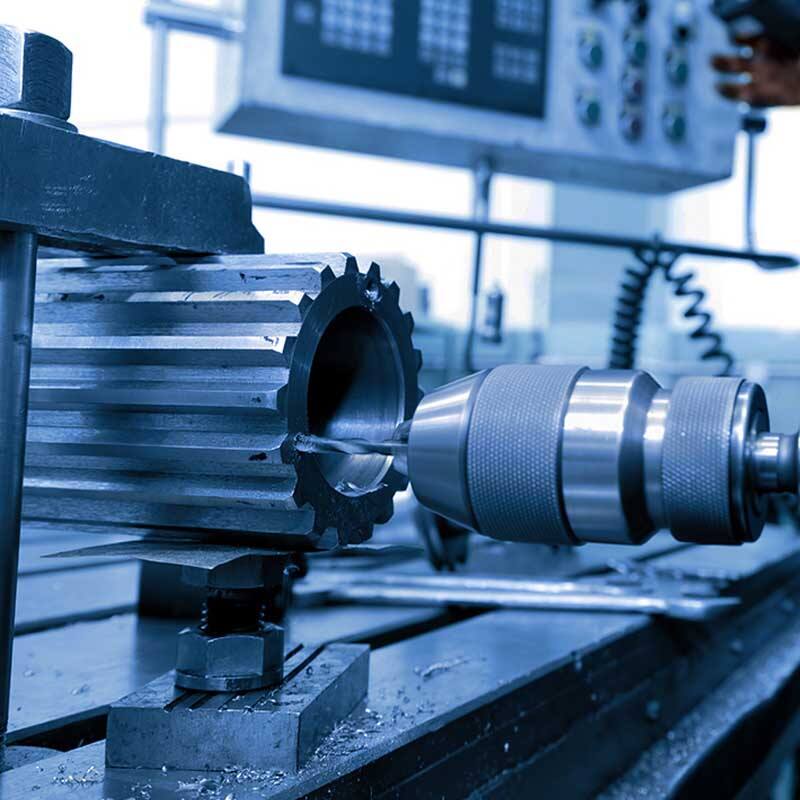

Broaching utilizes a specialized tool with multiple teeth to remove material in a linear motion, creating keyways, splines, and other complex shapes.

Sawing involves using a saw blade to cut through workpieces, producing straight or curved cuts.

Boring enlarges existing holes or creates precise internal diameters using a rotating cutting tool.

Tapping creates internal threads in a workpiece by rotating a tap into a pre-drilled hole.

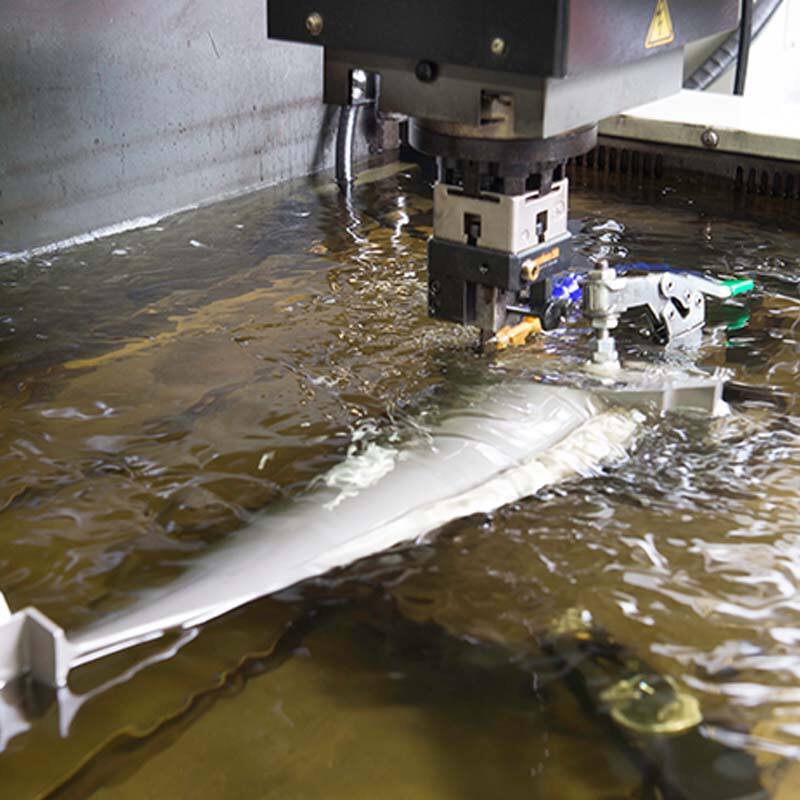

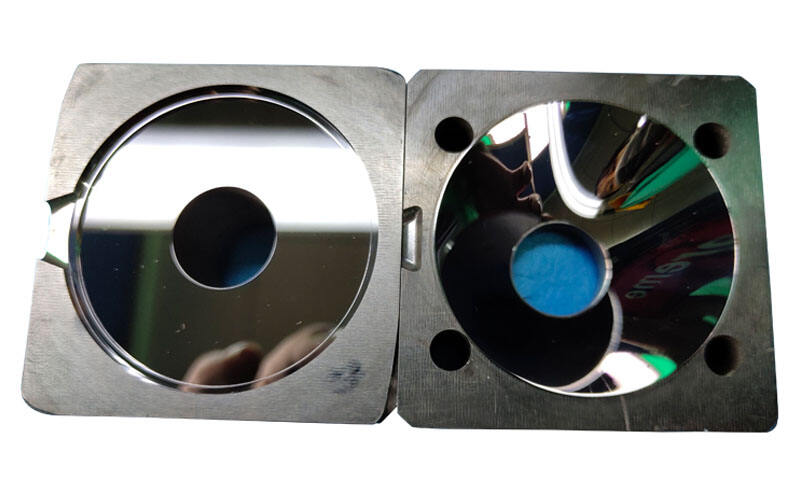

EDM uses electrical discharges to remove material from a workpiece, particularly for complex shapes or hardened materials.

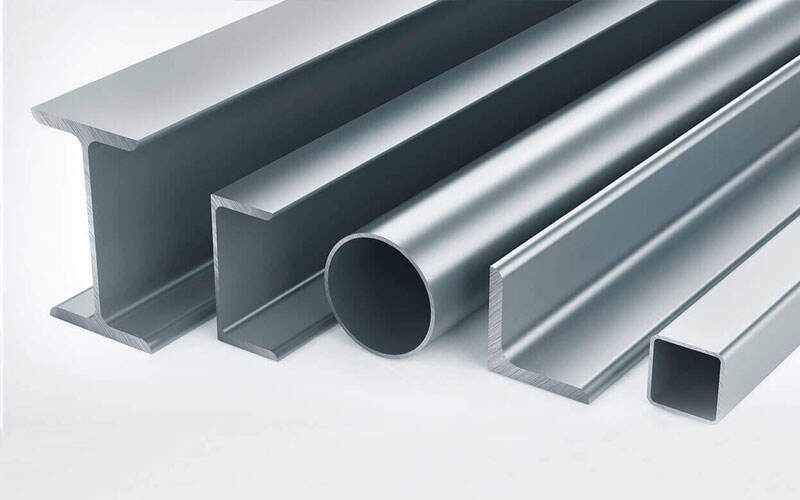

such as carbon steel, alloy steel, stainless steel, etc., commonly used for manufacturing mechanical parts and structural components.

known for its good strength and corrosion resistance, often used for manufacturing lightweight parts and structures.

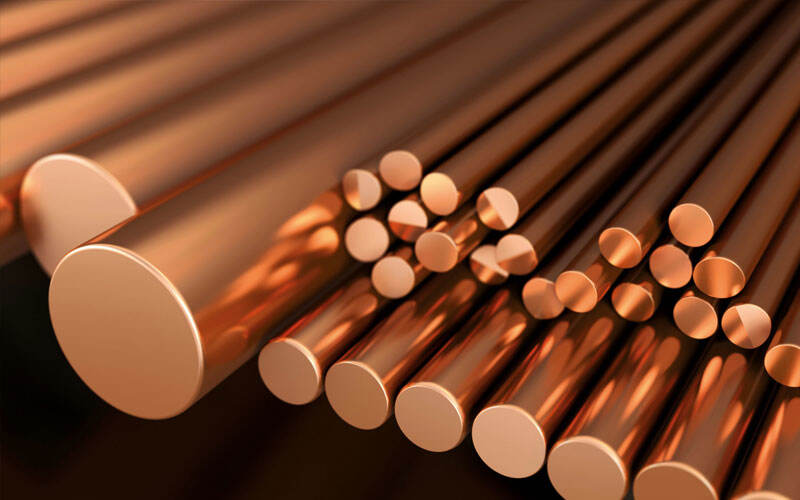

known for its excellent conductivity and thermal conductivity, commonly used for manufacturing electrical components and heat-conducting parts.

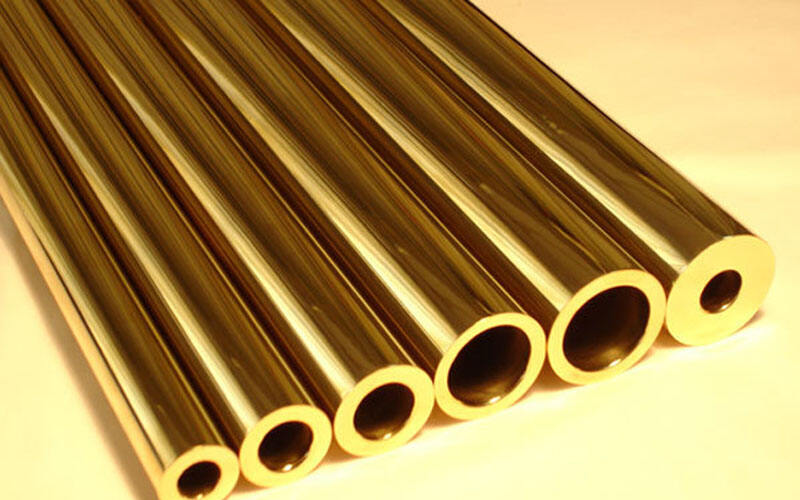

an alloy of copper and zinc, known for its good machinability and corrosion resistance, commonly used for manufacturing valves, pipes, and other components.

such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), etc., commonly used for manufacturing plastic parts and housings.

known for its good wear resistance and compression strength, commonly used for manufacturing mechanical parts and bases.

Improving the smoothness and appearance of the metal surface through grinding and polishing techniques.

Including electroplating, galvanizing, chromium plating, etc., depositing another metal or alloy onto the metal surface to enhance its properties or appearance.

Applying protective or decorative coatings using spray painting techniques.

Applying protective or decorative coatings using spray painting techniques.

Using high-pressure blasting to remove oxide layers and impurities from the metal surface, improving surface roughness.