Injection Molding: A Revolutionary Way to Create Amazing Things

Introduction:

Do you ever wonder how your favorite toys water bottles, and also car parts are produced? Well, they are made through a procedure called injection molding. Starway injection molding is a manufacturing process that uses molten molds material plastic generate things in large volumes. We will dive deeper into injection molding to know its advantages, innovations, security, its use, how exactly to put it to use, solution, quality, and applications.

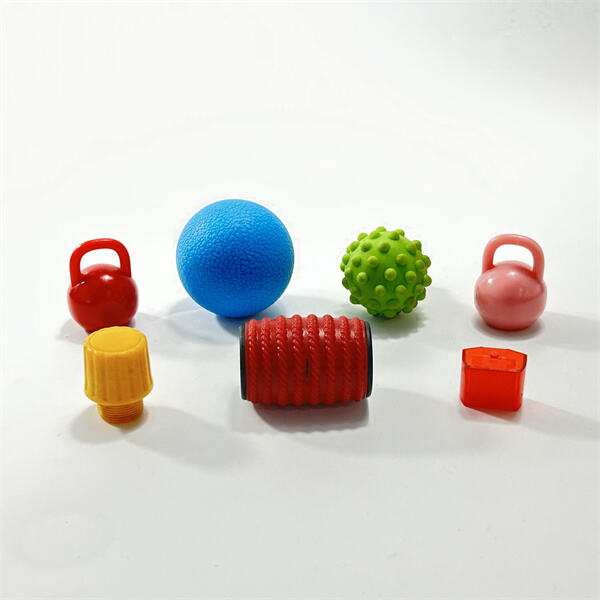

Injection molding has many advantages other manufacturing processes. injection molding is a really fast process can create multiple products in seconds. The parts produced from injection molding are particularly precise and from now on have constant proportions, making it a real perfect way manufacturing large volumes of identical components. Starway plastic injection can also be very flexible, which means that the molds could be customized based on the customers' needs. Plus, injection molding uses only a minimal amount of material, rendering it an eco-friendly procedure.

Using the constant advancements technology, Starway injection molding happens to become more efficient, reliable, and faster than ever before. For example, 3D printing has revolutionized the injection molding process. 3D printers can create prototypes and molds within few hours which dramatically boosts the entire injection molding process. Automating the process in addition has paid down labor costs and increased the production rate, making injection molding a more manufacturing affordable process.

Safety is a top priority everyone tangled up in the injection molding process. Safety guards are positioned all over machine to avoid injuries to your operators. Additionally, Starway plastic injection molding has different safety features are manufactured to the machine, such as automatic shut-off sensors that detect if anything goes wrong during the injection molding process. This helps to cut back the possibility of accidents and injuries while keeping everybody in the workplace safe.

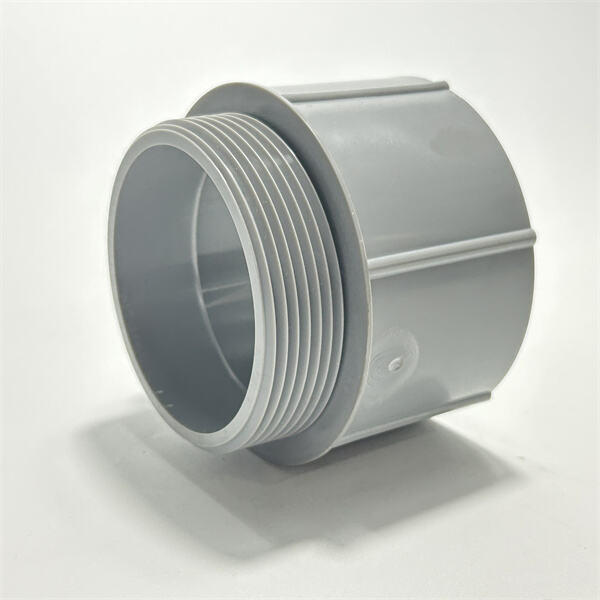

To use injection molding, a melted plastic resin is injected into a closed mold and this can be tailored based on the product to be produced. The Starway plastic molding -type material is then cooled, and also the mold is opened, releasing the finished product. The process could be duplicated huge number of times a day, which makes it a simple yet effective and manufacturing highly process productive.

order system advanced operates scientific efficiency, guaranteeing quick processing tracking every customer order. Through injection molding order management platform, customers effortlessly submit orders check status real-time. place high priority the precision delivery orders. addition, maintain open line communication our customers during entire manufacturing process. lets us respond swiftly requests design changes improvements. Each order handled same level attention, making sure processed promptly delivered high-quality manner. quality-focused approach demonstrates dedication surpassing customer expectations every interaction.

team service professionals includes pre-sales team proficient English business communication, as well injection molding adept product processing technology. Through collaboration between sales technical personnel, we able communicate effectively customers thorough understanding needs. We offer customers flexible, personalized processing solutions all-inclusive. team committed ensure that project running smoothly.

We well-known capacity create new ideas quickly injection molding. In thriving relationship clients rapid adaptation changes design product during development phase, offering expert insights refine sketches speed up process. We assisted clients make thousands products utilizing 15-years experience custom-made metal processing. clients enjoyed advantages competition because innovative products created. commitment excellence sure clients receive optimal solutions, allow to navigate complex landscape confidence.

injection molding open transparent services, always seeking long-term business cooperation customers. Integrity cornerstone business relationships. provide expert guidance fair pricing prior closing deals. In course production keep constant contact customers, ensuring they're informed developments. Additionally, are transparent manufacturing process, sharing updates addressing issues swiftly. Customers invited give feedback at time. Thanks transparent open approach, have forged solid long-term relationships increasing numbers customers.

After-sales services, such as product customization, maintenance, and repairs, are critical in ensuring the durability of the injection molding process. Machine manufacturers have well-trained technicians who provide after-sales services so that the smooth operation of. This Starway plastic injection moulding service also guarantees that machine breakdowns are addressed promptly, ensuring the prosperity of the injection molding process.

The grade of products produced through Starway injection molding is uncompromising. High-quality materials together with utilization of advanced injection molding technology make sure the precise dimensions performance standards are met. Dimensional accuracy and a consistent appearance two of the most extremely product significant created through injection molding. This final product of precise quality and consistency, plus the molds can be recycled for later use.

Injection molding is trusted across various industries and sectors, including medical, automotive, aerospace, and customer goods. Medical equipment, appliance handles, aerospace components, and meals containers, amongst others, are only a number of the services and products created through injection molding. The Starway has numerous option in different materials like custom metal stamping that can be used for an expansive range of, from small, intricate pieces to much bigger manufactured parts.