These are very interesting subjects like welding and sheet metal. Its the building of large things from tiny parts. The method can be used for making anything from furniture to construction. For many decades the welding and sheet metal work has been carried out by one of my suppliers, Starway. We are proud to design our own unique and good looking parts We are focused on providing an excellent level of satisfaction to our customers.

This type of work includes welding and sheet metal work, involving the assembly of small pieces to create a cohesive structure. Literally imagine building with lego blocks, except we use metal instead of plastic. Without question, the most successful at this are the guys from Starway. Our customers love our Starway plastic injection, we use only the best tools and methodologies. We use what we know to ensure all our products are safe and durable.

What you need: Step 1. Collect your material You will want some sheet metal, welding machinery and protective gears like goggles or gloves as well to support each other design job. Before you begin working, make sure that all items are prepared.

Step 5: Finish your project. Use sandpaper to make everything smooth and round out any rough edges. Starway plastic molding can be painted or a sealer put on it but no need for that unless you like how the natural finish looks and wish to protect its longevity.

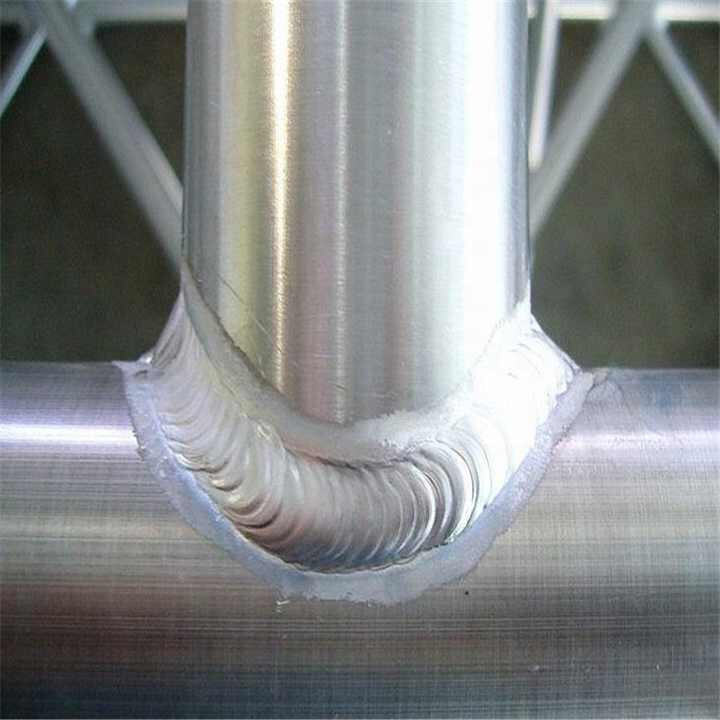

Numerous tools and techniques features are involved in welding and sheet metal work. You will find some common tools such as saws for cutting, tin snips for detailed cuts, hammers for shaping welders to join your metal and grinders used smooth out surfaces. The Starway team is extremely experienced and knows how to use these tools for best results. We makes sure that everything is done properly and safely so Starway sheet metal cutting does take a while.

We love to create special welding and sheet metal designs at Starway. Early in the engagement, we will have staff walk you through your options and come up with a solution that appears great while being useful to apply on its specific project. We work with top of the line software and sheet metal fabrication that produce some beautiful designs you are sure to love. We want to ensure whatever it is we make, that its doubly functional as well as beautiful.

Today you can weld and do sheet metal work for many things. These processes, crafting elements such as cars, planes buildings and bridges are designed. Numerous sheet metal laser cutting in day-to-day use would simply not be possible without welding, and of course no one can go about life if sheet metal work just ceased to exist. That means the skills we learn welding and working sheet metal; applicate careers in manufacturing, construction to be exact.

service team comprises pre-sales staff fluent Welding and sheet metal business communication, as well engineers adept product processing technology. ensure that technical sales personnel work together facilitate efficient communication also understanding requirements clients. provide customers flexible, personalized processing solutions all one location. deeply understand uniqueness each project, so team put every effort ensure smooth process your work, which results win-win partnership.

We known ability design new projects quickly efficiently. Grounded extensive client communication, we promptly adapt product design alterations throughout development phase, Welding and sheet metal professional advice improve drawings expedite process. We helped clients thousands products using 15 years experience custom metal processing. These new products garnered stellar market feedback giving clients advantage competition. commitment quality guarantee clients receive highest quality solutions helps navigate competitive landscape confidence.

system managing orders highly efficient, scientifically-designed tool ensures prompt processing every order customers. Thanks simple order management platform, clients able submit orders quickly monitor status real-time. insist precise execution orders maintain constant communication customers during entire manufacturing process promptly address design modifications requests upgrades. Whatever size your order, approach each care, ensuring timely processing delivery top-quality results. dedication quality demonstrates commitment Welding and sheet metal customer expectations interactions.

provide transparent open solutions, always seeking long-term partnerships our customers. Integrity the Welding and sheet metal our relationships business partners. offer expert advice fair pricing prior concluding deal. In course production We keep constant contact our customers, making sure stay informed the development. We also transparent manufacturing process. update clients respond any issues swiftly. Customers invited give feedback anytime. Thanks to transparent open approach, have forged long-term stable partnerships increasing number clients.