You can upload your design documents or machining requirements in this area to see instant pricing, delivery times and shipping times will have professional engineers feedback with you. Starway With dozens of machining processes, including CNC machining, metal welding, sheet cutting and injection molding, the Starway factory can provide you with a one-stop customized machining solution.

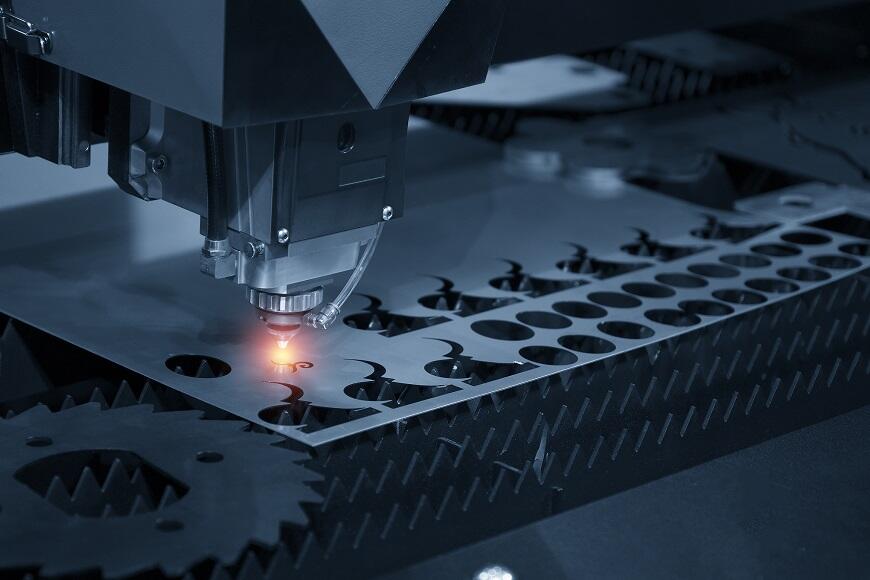

Laser cutting is a precision machining method that uses a high-energy laser beam to cut materials with great accuracy. The laser focuses on the material's surface, causing localized melting or vaporization to create clean, precise cuts. This technique offers fast speeds, smooth edges, and is ideal for complex shapes, while also minimizing material waste and improving efficiency.

Starway provides online customized laser cutting services. Our laser cutting services cover a wide range of materials including metal, plastic, rubber, etc. The laser cutting machines in Starway factory include: Nd:Yag Laser Cutting Machines, C02 Laser Cutting Machines, Nd Laser Cutting Machines. Our laser cutting machines can control the tolerance of the error to around 0.020", Starway also has a number of senior industry engineers and sales staff, can answer any customized questions and can provide you with a variety of questions about laser cutting processing.

You can get Instant quotes from 3D CAD files (file formats include :STEP, STP, SLDPRT, DXF, IPT, PRT, or SAT files) through our Instant Quoting Engine. Click for a timely quote

Starway's sheet metal laser cutting advantage

Our laser cutting slit is extremely narrow, usually 0.1mm~0.2mm, can be very fine cutting, suitable for high-precision parts production.

Due to the particularity of laser cutting, it can be processed without a mold, but it can be directly cut out complex graphics or Outlines through the CNC control system, which is especially suitable for small batch and diversified production needs.

Laser cutting speed is fast, especially fiber laser cutting, which can achieve extremely high cutting speed during sheet processing and reduce the production cycle (the thicker the corresponding laser cutting speed will also decrease).

The heat affected area generated by laser cutting is small, so the thermal deformation of the material is less, which is suitable for the processing of heat-sensitive parts.

Our laser cutting can almost meet a variety of complex cutting products and precision parts, higher material utilization, reducing material waste.

The edge after cutting is very smooth, usually no secondary processing, such as grinding or finishing, can be used directly for assembly.

Starway are proud of the core advantages that make the customers’ job easier, faster and more saving.

Dedicated service teams will be established for each project. (Pre-sales Team+ Pre-sales Engineers. )

In addition to laser cutting, we offer sheet metal bending, stamping, welding, CNC turning, milling, as well as product packaging and assembly services.

Rapid new product development:3 days prototype manufacturing

From the initiation meeting and confirmation of drawings to the first piece inspection, mid-term quality reports, and final product inspection, every step efficient execution.

1.Offer order reports at least twice a week

2.offer SOP operation manuals for batch orders

3.Comprehensive quality inspection reports

Obtain An Instant Quote by uploading a 3D CAD file (including STEP, STP, SLDPRT, DXF, IPT, PRT, or SAT formats) through our Instant Quoting Engine.

Starway provide the following metal materials for custom CNC laser cutting parts. Please note that the maximum part size may vary depending on material thickness.

| Material | Grade | Thicknesses Available |

|

Aluminum |

5052-H32 6061-T6 |

0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

|

Steel |

CRS/HRPO Galvanneal Galvanized |

0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

|

Stainless Steel |

304-2B 304 #4 316-2B |

0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

|

Copper |

C1010 C1100 |

0.025 in. - 0.125 in. (0.635mm - 3.175) |

|

Brass |

C260 |

0.025 in. - 0.125 in. (0.635mm - 3.175) |

This table contains general information about starway laser cutting services. To learn more you can click on us to get the latest information.

Most sheet metal material types can be machined using laser cutting technology, but the thickness range varies. The results are also different. Please refer to the following list for specific data:

| Maximum Size |

Thickness 0.134 - 0.250 in.: 39 in. x 19 in. Thickness 0.024 in - 0.134 in.: 39 in. x 47 in. |

| Minimum Part Size |

0.25 in. x 0.25 in. |

| Material Thicknesses | 0.024 in. - 0.250 in. |

| Tolerances |

+/- 0.005 in. for all features (except for hardware holes) +0.003/-0.000 in. on hardware insert holes to ensure correct |

| seating of inserts |

This table contains general information about starway laser cutting services. To learn more you can click on us to get the latest information.

Metal laser cutting is an advanced processing technology with high precision, high efficiency and strong adaptability. It mainly applies to the following fields:

Body and chassis parts: In automotive manufacturing, laser cutting technology can accurately cut out parts of the body and chassis, such as doors, roofs, exhaust pipes, etc.

Auto custom parts: Laser cutting supports small batch production and custom processing, such as custom appearance parts, modified accessories, etc.

Housing and support: Metal housing and internal support for household appliances such as refrigerators, washing machines, microwave ovens, etc., usually produced by laser cutting technology.

Electronic equipment sheet metal parts: Electronic equipment such as computers, servers, communication equipment in the metal chassis and other structural parts, usually by laser cutting completed.

Equipment housings and frames: Large frame and housing structures for industrial equipment, usually using metal sheets of varying thickness.

Mechanical parts: The internal structural parts and assembly parts of many mechanical equipment are also made of sheet metal, and the manufacturing error of parts is reduced by laser cutting processing.