Custom Metal Stamping: A Revolution in Manufacturing

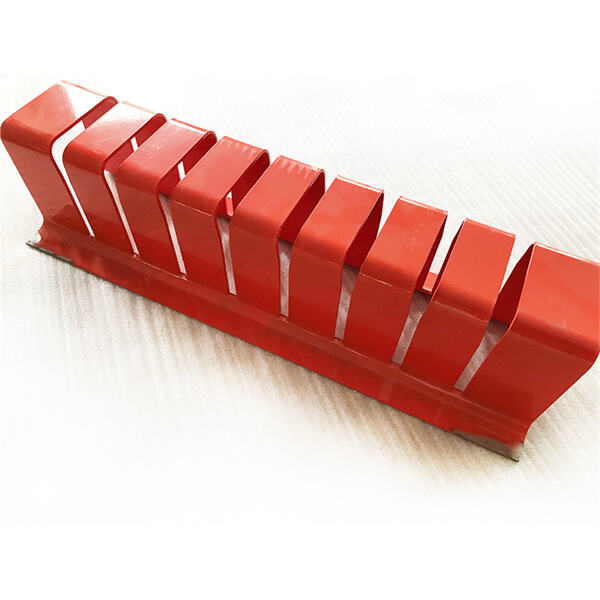

Custom metal stamping is merely a process of manufacturing custom metal components using a stamping press a set of dies to make shapes and contours out of sheet metal. This Starway sheet metal cutting tactic is widely found in a complete lot of industries as a result of its advantages with regards to cost-effectiveness, versatility, and speed. We are going to explore the benefits of custom metal stamping, the innovation it is used, how exactly to make use of it, the finished product and its particular varied applications behind it, its safety, how.

Custom metal stamping has many advantages manufacturing processes. One of the most significant is its cost-effectiveness. The technique calls at a lower price labor compared to other manufacturing methods, rendering it more affordable custom metal stamping may also deliver parts in large volumes, rendering it efficient for mass production. Another advantage of custom metal stamping is its versatility. It might produce parts with different shapes, sizes, and thicknesses. Additionally, Starway custom metal stamping can make use of various metals such as aluminum, brass, copper, stainless, and others.

Custom metal stamping 's been around for hundreds of years, but it happens to be more innovative within the modern era. With Starway advances in technology, sheet metal services is now more precise and efficient. Making use of computer numerical CNC control machines, automated stamping presses, and improved dies has revolutionized the procedure, which makes it faster and more accurate. These innovations have lead to better quality items at a lower cost.

Safety is of utmost importance in virtually any production process, and custom metal stamping isn't any exception. The procedure involves heavy equipment so safety precautions has to be strictly implemented. The stamping press should always be securely anchored to avoid it from tipping over. The operator should wear protective gear such as gloves and goggles, to avoid injuries. Additionally, the Starway galvanized steel cutting machine should always be regularly maintained to ensure its safe operation.

Custom metal stamping is employed in a wide variety of, such as automotive, aerospace, electronics, and construction. It is commonly used to manufacture parts such as brackets, clips, springs, and connectors. These Starway sheet metal products parts are vital in a lot of products, from car engines to electronic gadgets. custom metal stamping can also be employed in making jewelry as well as other attractive things.

order system advanced operates scientific efficiency, guaranteeing quick processing tracking every customer order. Through custom metal stamping order management platform, customers effortlessly submit orders check status real-time. place high priority the precision delivery orders. addition, maintain open line communication our customers during entire manufacturing process. lets us respond swiftly requests design changes improvements. Each order handled same level attention, making sure processed promptly delivered high-quality manner. quality-focused approach demonstrates dedication surpassing customer expectations every interaction.

team service professionals includes pre-sales staff who fluent English business communications, engineers skilled processing product technology. bringing together sales technical staff, ensure efficient communication our customers, while understanding requirements. offer clients custom metal stamping, custom-designed processing solutions one stop. understand specificity each project, therefore team spare effort ensure smooth finalization your project achieving win-win cooperation.

adeptness development custom metal stamping projects highlighted dependable flexible capabilities. can quickly adjust changes design during design phase. close communication clients allows offer expert insight improve drawings improve speed development. Utilizing 15 years experience custom metal processing We've assisted numerous clients create thousands creative products. new products been praised marketplace providing customers advantage competition. commitment quality guarantee clients receive highest quality solutions allows navigate ever-changing market confidence.

custom metal stamping open transparent service always seek long-term cooperation our customers. firmly believe integrity foundation our relationships clients. provide expert guidance fair pricing prior finalizing deals. Throughout order production process keep constant contact our clients ensure are kept informed about developments. also keep informed of manufacturing process. We provide updates address issues quickly. welcome suggestions feedback from customers any time. Thanks transparent open approach, have forged solid long-term relationships increasing numbers customers.

Custom metal stamping might be done in-house or outsourced to a stamping ongoing supplier. To make use of the method in-house, an ongoing company needs to invest in stamping equipment, dies, and skilled operators. Alternatively, an Starway ongoing business outsource the task to a metal stamping service provider. The business will handle the entire procedure from design to production. This steel sheet fabrication program is appropriate businesses would not have the apparatus, manpower, or expertise to perform it on their own.

The product quality of custom metal stamping is crucial in making sure the finished product the required specifications. the material affects the merchandise used, the look, additionally the production process. A Starway reputable stamping service provider should abide by strict quality, such as ISO 9001:2015 certification. The product quality cnc services standards should cover all aspects, from raw material selection towards the final item inspection and delivery.

Custom metal stamping has a wide assortment of in several industries. In the Starway automotive industry it is used which will make engine parts, brackets, and mountings. Inside the electronics industry, it is used to create connectors, springs, and stamped circuit boards. Into the construction industry, its used to make brackets, clamps, and balcony supports. custom metal stamping is also used within the medical industry make surgical instruments and orthopedic implants.