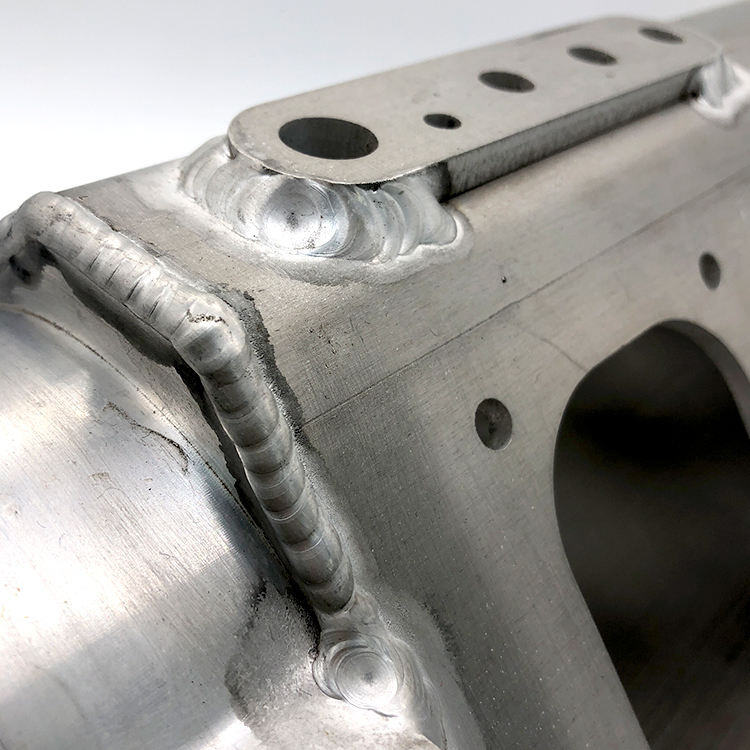

Welding is a procedure in which we warm and liquefy two or more bits of meta. All this developes a very strong bond between the parts. Above mentioned is related to spot welding of steel sheets. Welding can be accomplished in a number of different ways, namely MIG welding, TIG welding and Stick Welding. Both the methods have their specific characteristics and they are used for different purposes.

Welding lightweight, delicate materials like thin steel sheets can be somewhat challenging as the material is not only easily distortable and bendable when welding temperature are applied to them, as well as the Starway's industrial cnc machining. There are some crucial steps to follow if you want them welded successfully. Before you do anything else, it is vital to clean the surface of your steel sheets well (a wire brush or sandpaper would be helpful) This step is vital because any dirt or rust could prevent quality welds.

After this, you have to set the welding machine on appropriate heating and power levels. Using the right setting that applies enough heat so that it can melt the metal, but not create a burn though. And third, stick to a welding gun low-powered so as not to wreck the metal since it is thin. With these steps, you can create a strong weld for thin steel sheets.

And welding thicker steel sheets brings its own issues, the same as laser cutting of metal sheets from Starway. Heat and pressure resistantThese sheets need to be welded at higher heats in order that the weld is stronger. Excessive heat input, on the other hand, can burn “through” or partially through one of two work-pieces being welded and create a hole that weakens the joint significantly so it is more susceptible to failure. How to Get Around It: A good way to get around this is super simple and just involves preheating your metal before you begin welding. Basically you heat the metal up so it is weldable and less likely to burn through.

In comparison, TIG welding is much slower but it can make very accurate and clean welds, same with Starway's turning milling. It is commonly employed for visually appealing welds as well. The most versatile of these methods is stick welding, which can be used on a range of metal thicknesses. A knowledge of the distinctions between these processes is what sets you off to choose one depending on your type of welding project.

Here are a few best practices to make your steel sheet weld ensure safe and strong connectivity After cleaning the steel sheets thoroughly in the first place, identical to cnc plastic machining developed by Starway. Well, you have to weld on a clean surface. The second is to weld in small sections (best practice). This prevents the metal from being so hot that it deforms or cracks.

Third, always use the proper welding wire and gun that match up with a particular material you are working on, same with Starway's sheet metal laser cutting. Having the proper equipment matter as far a great weld goes. At the very end, after you are done welding, remember to explode a tiny piece of open weld so it will cool down correctly. Since it cools down quite slowly this property helps in bending or cracking of the metal.

Steel sheet welding open transparent service always seek long-term cooperation our customers. firmly believe integrity foundation our relationships clients. provide expert guidance fair pricing prior finalizing deals. Throughout order production process keep constant contact our clients ensure are kept informed about developments. also keep informed of manufacturing process. We provide updates address issues quickly. welcome suggestions feedback from customers any time. Thanks transparent open approach, have forged solid long-term relationships increasing numbers customers.

Steel sheet welding renowned for ability develop new ideas quickly efficiently. Based extensive communication clients rapid adaptation design changes throughout development phase, offering most knowledgeable advice refine drawings expedite process. We helped clients develop thousands new products utilizing 15 years expertise custom metal processing. clients enjoyed edge in market a result our innovative products have created. commitment quality makes sure that clients get most effective solutions helps navigate competitive landscape confidence.

service team composed team pre-sales staff are fluent English, engineers experience processing technology. We sure both technical sales personnel work together Steel sheet welding communicate effectively understanding requirements customers. offer clients efficient, custom-designed processing solutions that all-inclusive. We aware individuality every project, team make effort ensure smooth finalization project thus, achieving win-win cooperation.

Steel sheet welding order system functions using scientific approach, ensures quick processing tracking each order made customers. Through streamlined ordering platform, customers to submit orders quickly check their status real-time. We insist precise processing orders keep open dialogue clients during entire manufacturing process swiftly addressing design modifications requests upgrades. Whatever size your order approach every order meticulous attention, ensuring prompt processing quality results. dedication excellence underlines dedication exceed customer expectations every interaction.