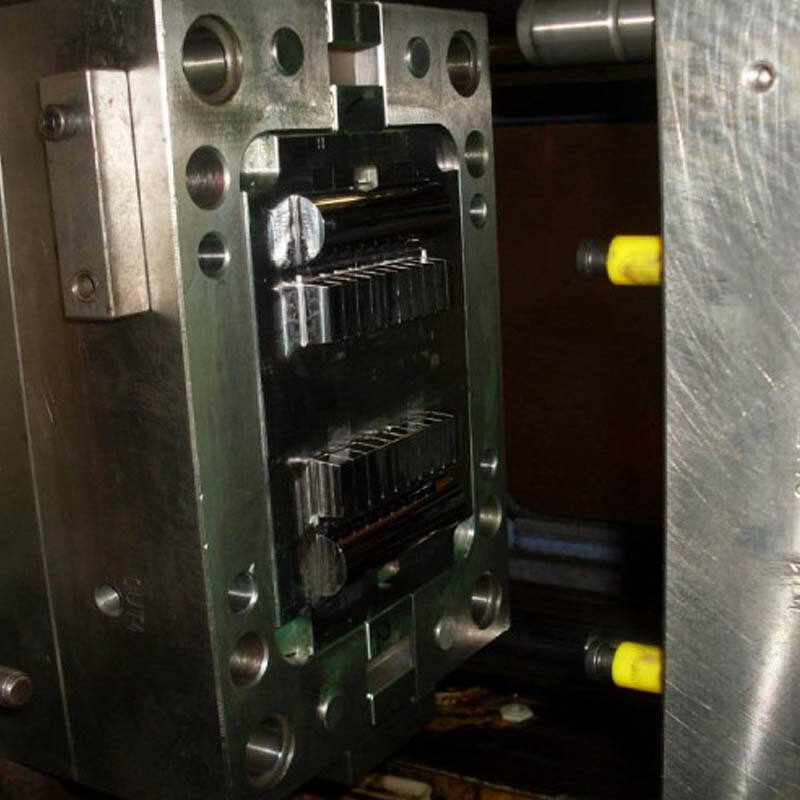

The most widely used method, where molten plastic is injected into a mold cavity under high pressure and cooled to form the desired shape.

Involves molding one material over another, typically to provide additional features or improve grip.

Involves placing metal or plastic inserts into the mold cavity before injection, allowing for the creation of parts with integrated components.

Uses nitrogen gas to assist in the injection process, reducing material use and improving part strength.

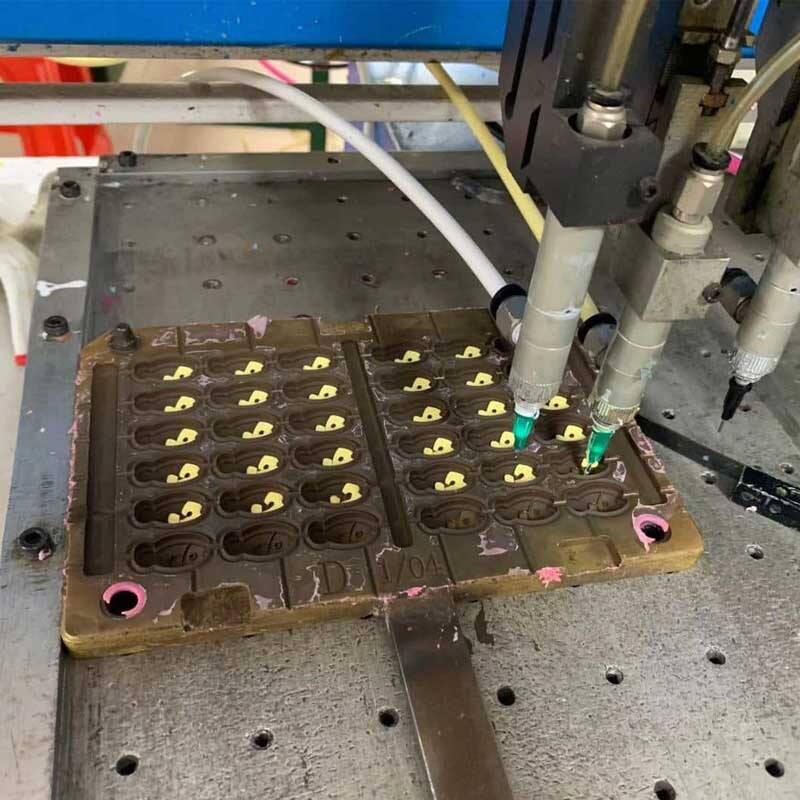

Involves injecting two different materials into the mold in separate stages, allowing for the creation of parts with multiple colors or materials.

Similar to two-shot molding, but involves injecting two different materials simultaneously into the mold, allowing for the creation of parts with a core and outer layer.

Polypropylene is a common thermoplastic with good chemical resistance and mechanical properties. It is widely used in the manufacturing of various plastic products such as bottle caps, containers, pipes, and automotive parts.

Polyethylene is a common plastic and comes in different types such as high-density polyethylene (HDPE) and low-density polyethylene (LDPE). It is used for making plastic bags, bottles, plastic films, and garbage bags, among other things.

PVC is a common plastic known for its chemical resistance and weather resistance. It is used in the production of water pipes, cable insulation, window frames, flooring, and more.

Polystyrene is a common plastic with two main types: General Purpose Polystyrene (GPPS) and High Impact Polystyrene (HIPS). It is used in making foam cups, food containers, electronic packaging, etc.

PET is a transparent and durable plastic commonly used for manufacturing plastic bottles, food packaging, fibers, and textiles.

Polycarbonate is a high-strength and heat-resistant plastic often used in the production of safety glasses, phone screens, CDs, and automotive parts.

PMMA is a transparent plastic used for making transparent sheets, decorations, automotive lamp covers, and eyeglass lenses.

Nylon (PA):Nylon is a high-strength, abrasion-resistant engineering plastic commonly used in the production of gears, bearings, ropes, and plastic parts.

ABS plastic is known for its impact resistance and mechanical properties, and it is used for making appliance housings, toys, and automotive parts.

PLA is a biodegradable bio-plastic widely used in disposable tableware, packaging materials, and medical implants.

Applying paint coatings to enhance color, gloss, or surface protection.

Applying special coatings to improve wear resistance, corrosion resistance, or other specific properties.

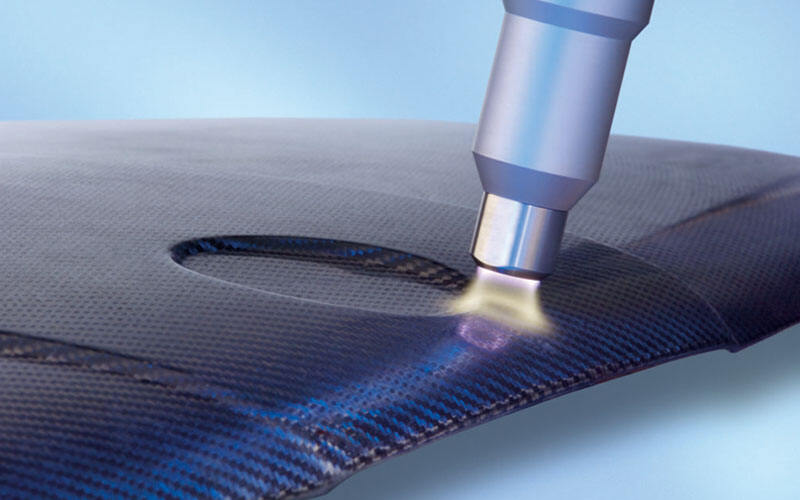

Improving surface adhesion, cleanliness, and wetting properties by placing injection molded products in special atmospheres, such as hydrogen, oxygen, etc.

Adding patterns, text, or logos onto the surface of injection molded products for decoration or branding purposes.

Mechanical polishing of the surface to improve smoothness and appearance quality.

Using hot stamping or foil stamping techniques on the surface of injection molded products to enhance decoration or brand awareness.