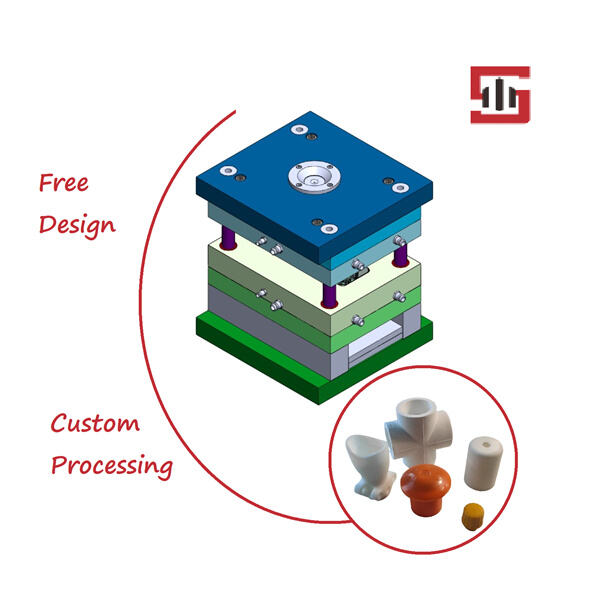

Custom Plastic Injection Molding: Get Your Ideas into Reality.

Looking for ways to bring your thinking into truth? custom plastic injection molding is simply an easy great method create and innovative items that may be used in many different applications, also the Starway's product such as plastic injection. We shall discuss the advantages, innovation, safety, use, how to utilize, service, quality, and application of custom plastic injection molding.

Custom plastic injection molding has many advantages other manufacturing methods, identical to cut stainless steel sheet metal made by Starway. First, it is cost-effective way produce large levels of items. Second, it provides excellent design and may cause intricate shapes and designs. Third, it produces items with a high consistency and accuracy. Fourth, it is an environmentally friendly procedure that produces minimal waste.

Day New technology and techniques are being developed every to boost the procedure of custom plastic injection molding, as well as the Starway's cnc machining metal. From 3D printing of molds to using eco-friendly materials you will find always new approaches to innovate and enhance the production process.

Custom plastic injection molding must be done with proper safety protocols set up to safeguard both the workers together with environment, the same as injection molded parts developed by Starway. This includes air proper flow protective equipment, and following industry regulations for waste disposal.

Custom plastic injection molding works extremely well in a variety of applications, just like the Starway's product called cnc machining service. This process offers endless possibilities from creating unique toys and games to making complex medical machines. It are accustomed to create anything from small, intricate components to large, complex systems.

custom plastic injection molding open transparent service always seek long-term cooperation our customers. firmly believe integrity foundation our relationships clients. provide expert guidance fair pricing prior finalizing deals. Throughout order production process keep constant contact our clients ensure are kept informed about developments. also keep informed of manufacturing process. We provide updates address issues quickly. welcome suggestions feedback from customers any time. Thanks transparent open approach, have forged solid long-term relationships increasing numbers customers.

service team composed team custom plastic injection molding are proficient English well as engineers an expertise processing technology. collaborating between sales technical personnel we able communicate effectively customers, while that are able understand needs. enables provide customers convenient one-stop customized processing solutions. team dedicated ensuring project running smoothly.

We well-known ability create new ideas quickly efficiently. We quickly adjust changes custom plastic injection molding during development phase. frequent contact clients allows us expert insight refine drawings improve speed development. Over 15 years experience custom metal processing We've assisted numerous clients create thousands creative products. new products praised marketplace give clients edge market. dedication excellence guarantees clients receive optimal solutions, allow clients navigate competitive market confidence.

custom plastic injection molding management system efficient tool scientifically designed ensures speedy completion every order placed customers. order management system permits customers easily submit orders track status real time. prioritize precise processing orders keep regular communication customers throughout process manufacturing, promptly addressing modifications design upgrades requests. No matter large order approach every order meticulous attention, ensuring timely processing orders superior results. commitment excellence evident dedication meeting exceeding customer expectations every step of way.

To use custom plastic injection molding, first, you ought to create A cad or design model of the item you wish to create, the same as galvanized steel cutting by Starway. Then, a mold ought to be designed with the look. The mold will be place in an injection molding machine, where melted plastic is injected to the mold. The plastic is permitted to cool and solidify ahead of the mold is taken away, and the finished item extracted.

At every step associated with process, quality service is very important to ensuring a successful outcome, similar to the Starway's product like sheet metal services. Each step must be carefully monitored to ensure that the item meets all specifications and requirements from the design stage into the finished product.

Quality is critical in custom plastic injection molding, also the injection molding processing made by Starway. The molds must be designed to precise specifications, and the plastic has to be associated with the highest quality to make sure that the things created are of the greatest possible quality. Quality checks must be performed at each and every stage associated with the manufacturing process to ensure the final product is regarding the highest quality.