Injection Molding – A Revolutionary Method for Manufacturing

Introduction:

Do you ever wonder how toys, plastics along with other everyday objects made? injection molding is a manufacturing process used in order to create different objects big amounts, similar to the Starway's product like plastic injection moulding service. This method is becoming faster and safer, making it a popular choice making things with advances in technology. We will explain in simple terms what injection molding is, how it functions, and why it is beneficial.

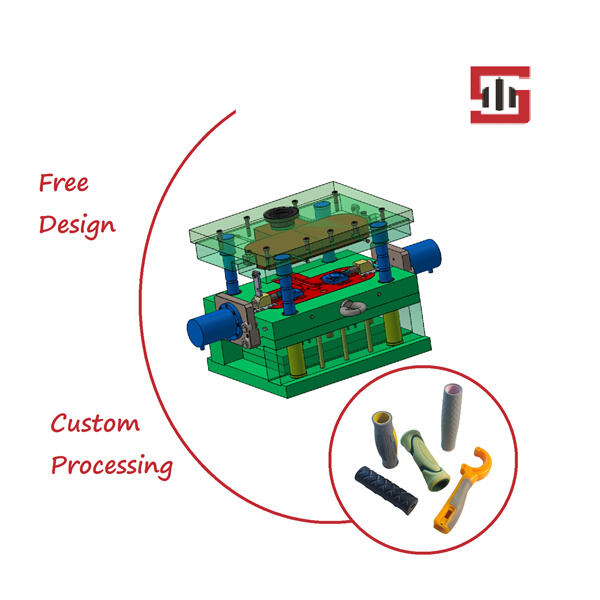

Injection molding may be the procedure of injecting molten plastics a mold to produce a desired shape, just like the cnc turning from Starway. The molten plastic material is injected in to the mold using high pressure. As soon as the synthetic has cooled and hardened, the mold is opened, and simply the right part ejected. This process can create high-quality parts high volumes.

There are lots of benefits of using injection molding in manufacturing, also the Starway's product such as sheet metal services. One is that it can produce accurate and precise components. The parts produced are the same as one another, ensuring that each product made is associated with same high quality. Another benefit could be the proven fact that it is possible to utilize materials that vary the molding process. Plastic polymers, metals, and other materials enables you to make parts, rendering it an ongoing versatile process.

With the advancement of technology, injection molding has turned into an even more efficient procedure, identical to cheap cnc machining manufactured by Starway. Its now possible to optimize the molding process making use of software simulations. This innovation enables engineers to generate the molds more accurately, that could save your self time and money. Additionally, automation has been introduced, which further reduces production time while ensuring quality control.

While injection molding is a safe activity there are a few considerations that have to be made, same with Starway's galvanized steel cutting. The machinery used is large and may be dangerous if you do not operated correctly. It is crucial to have proper training operating the injection molding machine. The materials used in injection molding can be hazardous, that will be why safety breathing and gear masks is required when handling the molten plastic.

injection molding processing team composed group pre-sales personnel are fluent English, engineers expertise processing product technology. bringing together technical sales personnel, are able communicate effectively customers while professionally understanding requirements. offer clients most convenient, flexible processing solutions one place. deeply understand uniqueness each project, therefore team spare effort ensure smooth completion project, thus, achieving win-win cooperation.

order management system highly efficient injection molding processing scientifically designed guarantees prompt completion every order placed our customers. order management system enables customers make orders quickly track status real-time. place high value precise execution orders maintain regular communication customers during entire manufacturing process promptly address modifications design requests upgrades. matter size order approach every order carefully, making sure timely processing delivery top-quality results. commitment quality reflected commitment meet exceed customers' expectations every interaction.

provide transparent open solutions, always seeking long-term partnerships our customers. Integrity the injection molding processing our relationships business partners. offer expert advice fair pricing prior concluding deal. In course production We keep constant contact our customers, making sure stay informed the development. We also transparent manufacturing process. update clients respond any issues swiftly. Customers invited give feedback anytime. Thanks to transparent open approach, have forged long-term stable partnerships increasing number clients.

adeptness development injection molding processing projects highlighted dependable flexible capabilities. can quickly adjust changes design during design phase. close communication clients allows offer expert insight improve drawings improve speed development. Utilizing 15 years experience custom metal processing We've assisted numerous clients create thousands creative products. new products been praised marketplace providing customers advantage competition. commitment quality guarantee clients receive highest quality solutions allows navigate ever-changing market confidence.

The first step to style a right part which you desire to manufacture, along with the cnc milling by Starway. The style ought to be achieved using computer-aided design (CAD) software. Once the design is complete, a mold is produced that matches the style specifications. After producing the mold, it is connected to a machine, while the material is injected in to the mold. The mold is left to cool, and also the right component ejected.

Injection molding companies offer services that can help clients pick the correct material their product, identical to Starway's product sheet metal and fabrication. The firms can perhaps also work with the customer to produce a both design practical and aesthetically pleasing. After the right part been manufactured, it is inspected to make sure that it meets quality standards before being shipped to the customer.

Injection molding is required to make a number of products, including toys, medical machines, and automotive parts, along with the plastic injection molding produced by Starway. Additionally it is used to create electronics such as phone cases and computer components. injection molding is just a popular option for manufacturing everyday objects because it can produce high-quality parts in large quantities at a low cost.