The Benefits of CNC Machining Metal for your Company

Intro:

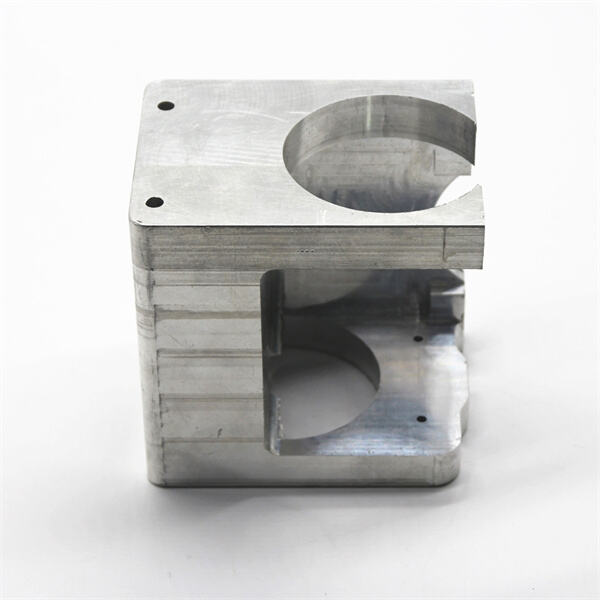

CNC machining metal is an advanced altering genuine method innovation that companies run. It is a type of production treatment that utilizes computer-controlled devices produce complicated metal. Starway cheap cnc machining is revolutionizing the machining market through enhancing security, quality and effectiveness. Our team will check out the benefits of utilization cnc machining metal, ways to utilize it, and its own specific different applications.

The significant benefits of CNC machining metal include speed, consistency, and precision. CNC machines can produce parts faster than conventional machines, thereby improving efficiency. With the capability to create precise metal components, there is no need for manual labor, reducing both time and labor. Furthermore, Starway cnc machining are consistent, ensuring high-quality results with every use.

CNC machining metal is an innovative technology that is continuously evolving. As new machines are developed, the capabilities of Starway cnc machining metal continue to expand. Manufacturers are constantly exploring new ways to utilize CNC to produce unique shapes, tools, and components. The ongoing development of CNC machining will help businesses attract new customers and expand into new markets.

CNC machining metal is also safer than traditional manufacturing methods. With manual equipment, there is a risk of injury due to human error or mishandling of tools. With Starway cnc machining part, the risk of injury is minimal because everything is actually automated. The machine does not require an operator to be close, reducing the risk of accidents.

CNC machining metal is straightforward to use. Once the Starway cnc services is programmed, it operates mostly on its own. This allows operators to focus on other tasks while the machine completes the work. As a result, CNC machines are more cost-effective than traditional methods, as manufacturers can save on labor costs and reduce the time needed to produce components.

cnc machining metal open transparent service always seek long-term cooperation our customers. firmly believe integrity foundation our relationships clients. provide expert guidance fair pricing prior finalizing deals. Throughout order production process keep constant contact our clients ensure are kept informed about developments. also keep informed of manufacturing process. We provide updates address issues quickly. welcome suggestions feedback from customers any time. Thanks transparent open approach, have forged solid long-term relationships increasing numbers customers.

order cnc machining metal system highly efficient, scientifically-designed tool ensures speedy processing each customer order. streamlined order management platform, customers are to submit orders quickly monitor status real-time. We a high priority precision execution orders, we remain constant contact communicate customers throughout entire production process. lets respond swiftly any requests design modifications improvements. Whatever size your order approach every order care, ensuring prompt processing high-quality outcomes. dedication quality demonstrates determination exceed customer expectations every interaction.

We cnc machining metal ability create new projects quickly efficiently. In thriving relationship our clients quick adaptation changes design throughout process design, providing most knowledgeable advice refine sketches speed up process. We assisted clients develop thousands new products 15 years expertise custom metal processing. clients enjoyed competitive advantage thanks innovative products designed. commitment quality ensures clients get most effective solutions helps navigate competitive landscape confidence.

service team cnc machining metal pre-sales group is proficient English well as business communication as well engineers skilled processing product technology. Through collaboration between sales technical staff, guarantee efficient communication our customers, while understanding requirements. This enable offer customers convenient one-stop customized processing solutions. understand specificity each project, our team spare effort ensure smooth completion your project, which results a win-win partnership.

Using CNC machining metal is straightforward. The first step is to program the Starway cnc machining service machine. Once programmed, the operator loads the materials onto the machine bed and starts the machine. The machine takes over from there, performing all the necessary operations to produce the desired part.

CNC machining metal requires little to no maintenance. Once the machine is programmed, it can operate for long periods without breaking down. Unlike traditional equipment, there is no need for regular repairs or maintenance. This means that CNC machines are more reliable than traditional machines, reducing downtime for businesses.

CNC machining metal produces high-quality components consistently with each use. Traditional methods require manual labor to operate machines, which can lead to variations in quality. With CNC machining, there is no human error to worry about, so the results are always consistent. Additionally, since CNC machines are operated by computers, they can detect and correct any errors before they result in a defective product.