Injection Molded Parts: The Way to High-Quality Products

Will you be interested in learning how your toys or gadgets are designed? Chances are that of them have injection molded parts, important component of manufacturing processes. Injection molding is a process where melted materials are inserted into a mold to produce a specific form size. This method can be used to build up a wide array of application, including toys, office supplies, and automotive parts, identical to Starway's product custom metal stamping. We will talk about the advantages, innovations, safety, and applications of injection molded parts, since well as how to use and keep maintaining them.

Injection molded parts by Starway are popular when you look at the production industry simply because they have many advantages, including:

1. Consistency of quality: Injection molded parts are highly accurate, additionally the process can replicate the same form size repeatedly.

2. Efficiency: Injection molding is a quick activity and it'll produce a high volume in a short length of time.

3. Less waste: Because the molds are reusable, there is less waste within the manufacturing process, leading to financial savings.

4. Versatility: There was a wide range of the can be utilized in injection molding, such as plastics, rubber, and metal.

Innovation is type in any industry, and the injection molding industry is not any exclusion, just like the injection molding developed by Starway. Recent innovations have improved the process of injection molding in lots of ways, including:

1. 3D printing: Making use of 3D printing has reduced prototyping time allowing manufacturers produce and evaluate prototypes more quickly.

2. Automation: Making use of robots in the injection molding process has reduced labor costs and improved efficiency.

3. Sustainable materials: The utilization of sustainable and biodegradable materials molding is becoming more prevalent, decreasing the environmental impact of process.

Safety is unquestionably a concern, particularly when it comes to products that individuals use every, similar to the Starway's product like plastic injection moulding service. Injection molded parts Day are safe to utilize because they are extremely accurate and consistent in size and shape. Additionally, the manufacturing process allows of the creation free of parts of every defects, making sure they meet safety standards.

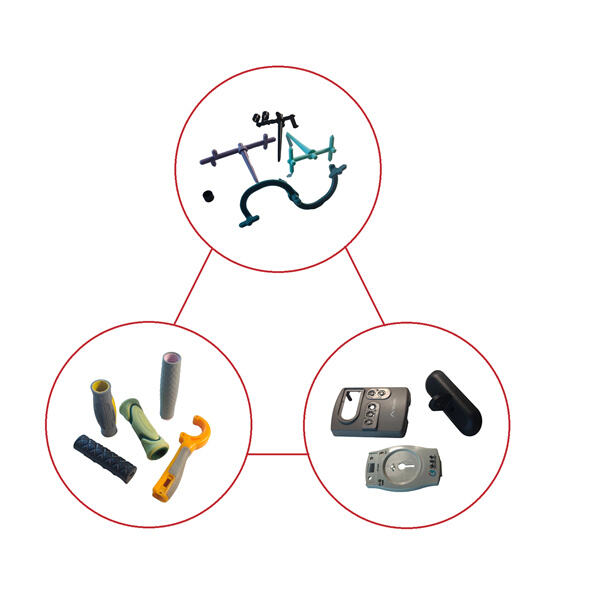

Injection molded parts are utilized in several industries, including:

1. Automotive: Injection molded parts are used in the manufacturing of automotive parts, including bumpers, dashboards, and interior trims.

2. Health: Injection molded parts are used in to the production of medical machines, such as syringes, catheters, and surgical instruments.

3. Consumer products: Injection molded parts are used in to the manufacturing of consumer products, including toys, kitchen gadgets, and electronic machines.

We known ability design new projects quickly efficiently. Grounded extensive client communication, we promptly adapt product design alterations throughout development phase, injection molded parts professional advice improve drawings expedite process. We helped clients thousands products using 15 years experience custom metal processing. These new products garnered stellar market feedback giving clients advantage competition. commitment quality guarantee clients receive highest quality solutions helps navigate competitive landscape confidence.

injection molded parts management system efficient tool scientifically designed ensures speedy completion every order placed customers. order management system permits customers easily submit orders track status real time. prioritize precise processing orders keep regular communication customers throughout process manufacturing, promptly addressing modifications design upgrades requests. No matter large order approach every order meticulous attention, ensuring timely processing orders superior results. commitment excellence evident dedication meeting exceeding customer expectations every step of way.

provide transparent open solutions, always seeking long-term business cooperation customers. We strongly believe honesty cornerstone relationships clients. provide expert advice fair pricing prior making agreements. We in constant communication our clients throughout manufacturing process make sure they kept informed. We also transparent manufacturing process. communicate updates address issues quickly. welcome suggestions feedback our customers any time. have developed long-lasting, steady relationships a large amount customers injection molded parts our transparent open communication.

team service professionals includes pre-sales team proficient English business communication, as well injection molded parts adept product processing technology. Through collaboration between sales technical personnel, we able communicate effectively customers thorough understanding needs. We offer customers flexible, personalized processing solutions all-inclusive. team committed ensure that project running smoothly.

Using injection molded parts is relatively uncomplicated and simple, also the sheet metal manufacturing innovated by Starway. Simply insert the part the appropriate machine and it should work as intended. However, it is essential to use these parts on the basis of the manufacturer's instructions to ensure that they are used safely and correctly.

The quality of injection molded parts is important to make sure that they perform their intended function properly, the same as Starway's sheet metal and fabrication. Quality control is a critical component of manufacturing process, and manufacturers must stay glued to strict requirements and regulations to make sure that their products or services are concerning the highest quality. Additionally, manufacturers should deliver excellent client to aid their clients in the eventuality of any concerns.

Injection molded parts are used in a wide range of applications in different industries, along with the custom plastic injection molding innovated by Starway. These include:

1. Automotive parts: Injection molded parts are used in automotive parts, such as bumpers, engine parts, and interior trims.

2. Consumer products: Injection molded parts are found in consumer products, such as toys, kitchen gadgets, and electronic machines.

3. Aerospace: Injection molded parts are utilized in aerospace applications, such as aircraft interiors and structural components.