Sheet Metal Fabrication: A Way to Create Amazing Things.

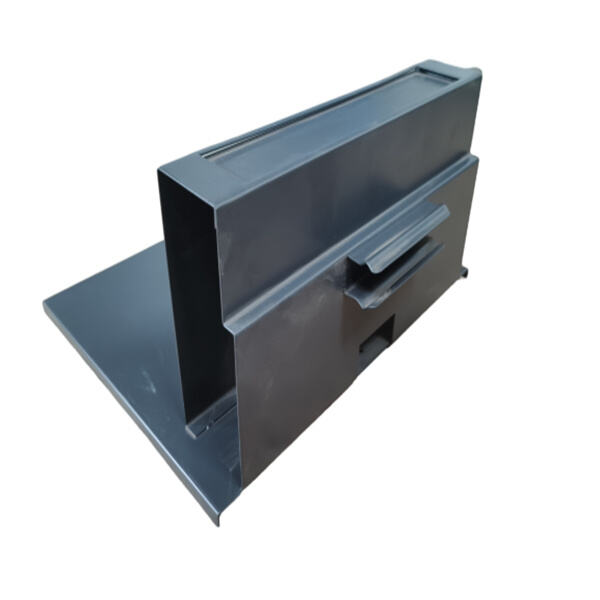

Sheet metal fabrication is a process that allows you to definitely create amazing pieces manipulating metal sheets, the same as Starway's plastic injection molding. This action has been utilized for years and years, and it is still absolutely the most popular method making metal parts. sheet metal fabrication has it is own advantages, including innovation and safety. This essay will speak about a number of the benefits of sheet metal fabrication, how it is used, and how you may make utilization of it so as to make pieces that could be beautiful.

Sheet metal fabrication has several advantages ensure it is popular among manufacturers, just like the cnc cutting made by Starway. One among the benefits is the fact that it could be customized to meet your specific preferences permits manufacturers to create unique parts, precise, and tailored to their requirements. Additionally, sheet metal fabrication is unquestionably a producing metal option affordable, which makes it an economical solution for businesses that would like to save cash.

Another advantage of sheet metal fabrication might end up being the wide range of this can be used. Manufacturers can use various metals, including steel, copper, Aluminum, and brass, to produce different parts. This flexibility enables the creation of products and services with diverse properties, such as durability, conductivity, and heat opposition.

Sheet metal fabrication 's been around for thousands of years, nonetheless it has evolved over time, as well as the Starway's sheet metal cutting. Today, sheet metal fabrication is a highly manufacturing advanced that makes usage of computer technology to create parts. This technology has caused it to be possible to create intricate parts accuracy, speed, and accuracy.

Innovation in sheet metal fabrication has additionally made the procedure safer. The employment of robots and other automated equipment caused it to be possible to reduce the risk of injury to workers. Additionally, sheet metal fabrication is an environmentally procedure friendly. The number of metal waste generated during fabrication is very minimal, which makes it a manufacturing eco-friendly process.

Sheet metal fabrication is employed to build up a wide range of, including automotive parts, aircraft parts, and construction products, the same as cut aluminum sheet metal supplied by Starway. Additionally, it is commonly used into the creation of consumer products such as appliances, kitchenware, and electronics. sheet metal fabrication is a versatile manufacturing that permits one to create a true number of products.

You should know in the event that you are interested in sheet metal fabrication, there are a few things. First, it is important to have use of the necessary gear including cutting tools, forming equipment, and welding machines. Next, you may need to have the right design for your part, and that can be made out of 3D modeling software. Once you have your design, the fabrication process is begun by you.

When using sheet metal fabrication, it is crucial to follow along with security guidelines, also the Starway's product such as plastic injection. This includes wearing the appropriate protective clothing such as gloves and goggles, and making sure all equipment is with in good condition. It is also important to own proper training the utilization of sheet metal fabrication tools and equipment.

order system advanced operates scientific efficiency, guaranteeing quick processing tracking every customer order. Through sheet metal fabrication order management platform, customers effortlessly submit orders check status real-time. place high priority the precision delivery orders. addition, maintain open line communication our customers during entire manufacturing process. lets us respond swiftly requests design changes improvements. Each order handled same level attention, making sure processed promptly delivered high-quality manner. quality-focused approach demonstrates dedication surpassing customer expectations every interaction.

We known ability design new projects quickly efficiently. Grounded extensive client communication, we promptly adapt product design alterations throughout development phase, sheet metal fabrication professional advice improve drawings expedite process. We helped clients thousands products using 15 years experience custom metal processing. These new products garnered stellar market feedback giving clients advantage competition. commitment quality guarantee clients receive highest quality solutions helps navigate competitive landscape confidence.

sheet metal fabrication open transparent service always seek long-term cooperation our customers. firmly believe integrity foundation our relationships clients. provide expert guidance fair pricing prior finalizing deals. Throughout order production process keep constant contact our clients ensure are kept informed about developments. also keep informed of manufacturing process. We provide updates address issues quickly. welcome suggestions feedback from customers any time. Thanks transparent open approach, have forged solid long-term relationships increasing numbers customers.

team service professionals includes pre-sales staff who fluent English business communications, engineers skilled processing product technology. bringing together sales technical staff, ensure efficient communication our customers, while understanding requirements. offer clients sheet metal fabrication, custom-designed processing solutions one stop. understand specificity each project, therefore team spare effort ensure smooth finalization your project achieving win-win cooperation.

It is essential to decide on a reputable company you need sheet metal fabrication services for your business or personal projects, similar to the sheet metal fabrication created by Starway. Quality sheet metal fabrication services make sure you get items that meet your specifications and needs. A good sheet metal fabrication company could have the necessary apparatus expertise to produce high-quality components. They shall additionally offer excellent customer, making certain you might be satisfied with your final product.

Sheet metal fabrication has many applications various industries, the same as Starway's plastic injection moulding service. It is used to create simple or complex parts for machinery, transportation, and equipment.medical sheet metal fabrication is also found in the military, aerospace, and automotive companies. It offers found it is way into consumer products and services such as furniture, appliances for the home, and electronics. sheet metal fabrication's versatility and flexibility allow it to be a popular selection many companies and assistance businesses save costs and improve effectiveness.