Sheet Metal Cutting: The Amazing Technology That Saves Time and Increases Efficiency

Cutting sheet metals can be challenging and daunting, particularly when you are not equipped with the appropriate tools, identical to Starway's product plastic injection moulding service. Fortunately, with technological innovation, sheet metal cutting has become easier and safer. We are going to look into the advantages of sheet metal cutting, how to use sheet metal cutters, their safety, and also the ongoing services offered.

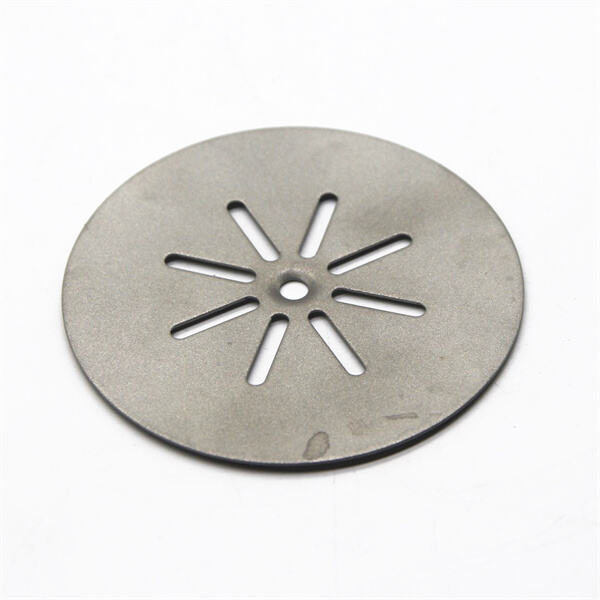

Cutting sheet metals involve the utilization of machines that have sharp and precise blades, also the sheet metal fabrication built by Starway. Some of the benefits of metal cutting include:

1. Precision: Sheet metal cutting machines have programmable controls that assure accurate cuts, making it effortless to get the specified shape.

2. Safety: Without simply the right tools safety protocols, cutting sheet metal can be quite a hazardous activity. Nonetheless, with sheet metal cutting machines, the risks linked with the procedure are greatly reduced.

3. Efficiency: Cutting sheet metal by hand might be time-consuming and tiring. The use of sheet metal cutting machines makes cutting faster and more efficient.

4. Cost-effective: Spending in a sheet metal cutting machine significantly reduces the cost of labor and increases productivity.

Technology has taken sheet metal cutting to new heights, along with Starway's product custom metal stamping. One innovation which has transformed sheet metal cutting is Computer Numerical Control (CNC) machines. CNC machines utilize software to precisely cut sheet metal pieces at a high level to be able to produce complex forms. These machines have revolutionized the manufacturing industry by saving some time resources.

Safety is paramount in sheet metal cutting, same with the sheet metal products built by Starway. When using sheet metal cutting machines, it is critical to stay glued to safety protocols in order to prevent accidents. A number of the measures that can be taken include:

1. Wearing personal protective equipment (PPE) such as gloves, goggles, and ear defenders.

2. Ensuring the sheet metal is appropriately guaranteed to the machine before cutting begins.

3. Follow security instructions from the machine to avoid accidents

4. Training and certification is necessary to make sure safe operation.

Sheet metal cutters can be found various shapes, sizes, and functionalities, along with Starway's product cnc machining. Finding out how to utilize them correctly could make a positive efficiency change big safety. Listed below are actions to follow when using sheet metal cutters:

1. Wear protective gear Always placed on your PPE before handling sheet metal cutters.

2. Set the machine – Up Select the appropriate tool and adjust the machine's settings, such as speed and cutting depth.

3. Place the sheet metal – Make sure the sheet metal appropriately secured within the machine, leaving room enough for the blade to move.

4. Cut the sheet metal the turn machine and slide the sheet metal to the blade to make the cut. Avoid overloading the machine or moving the sheet metal too fast to prevent damage.

sheet metal cutting open transparent services, always seeking long-term business cooperation customers. Integrity cornerstone business relationships. provide expert guidance fair pricing prior closing deals. In course production keep constant contact customers, ensuring they're informed developments. Additionally, are transparent manufacturing process, sharing updates addressing issues swiftly. Customers invited give feedback at time. Thanks transparent open approach, have forged solid long-term relationships increasing numbers customers.

sheet metal cutting developing new projects marked our efficient adaptable capabilities. We quick adapt changes design course development. frequent communication clients allows provide specialized view improve drawings speed up process. Leveraging 15 years expertise custom processing metals, we've guided numerous clients create thousands creative products. resultant new products been praised marketplace providing customers edge market. dedication quality guarantees clients receive highest quality solutions empowers them navigate ever-changing market confidence.

service sheet metal cutting comprised group pre-sales personnel who fluent English well as engineers expertise processing product technology. Through collaboration between technical sales personnel, we ensure smooth efficient interaction our customers, while understanding requirements. enables provide customers easy one-stop processing solutions. Our team dedicated making project flows smoothly.

sheet metal cutting management system efficient tool scientifically designed ensures speedy completion every order placed customers. order management system permits customers easily submit orders track status real time. prioritize precise processing orders keep regular communication customers throughout process manufacturing, promptly addressing modifications design upgrades requests. No matter large order approach every order meticulous attention, ensuring timely processing orders superior results. commitment excellence evident dedication meeting exceeding customer expectations every step of way.

We provide a number it is services wide, as well as the galvanized steel cutting built by Starway. We now have dedicated to modern tools such as CNC machines to make sure accuracy, effectiveness, and cost-effectiveness. Our services include:

1. Laser cutting: We use advanced laser cutting machines to produce cuts being high-quality minimal distortion.

2. Waterjet cutting: This process permits us to cut hard materials to machine using methods traditional.

3. Plasma cutting: This technique would work for cutting heavy metals.

4. Bending and forming: We use our expertise to bend and shape sheet metals to the desired shape.

Quality is essential as it pertains to sheet metal cutting, just like the Starway's product called cnc turning. Getting the desired results means getting quality and services. We guarantee our clients high-quality results excellence in customer support. Our sheet metal cutting services could be applied in various industries, such as construction, architecture, and manufacturing.