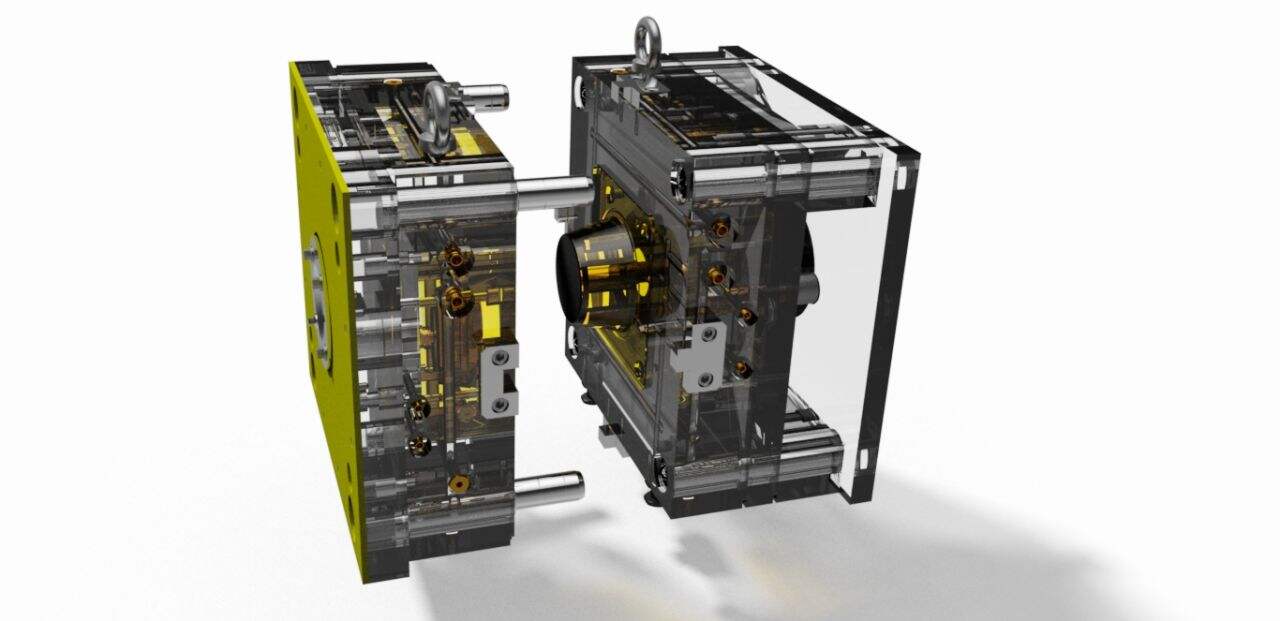

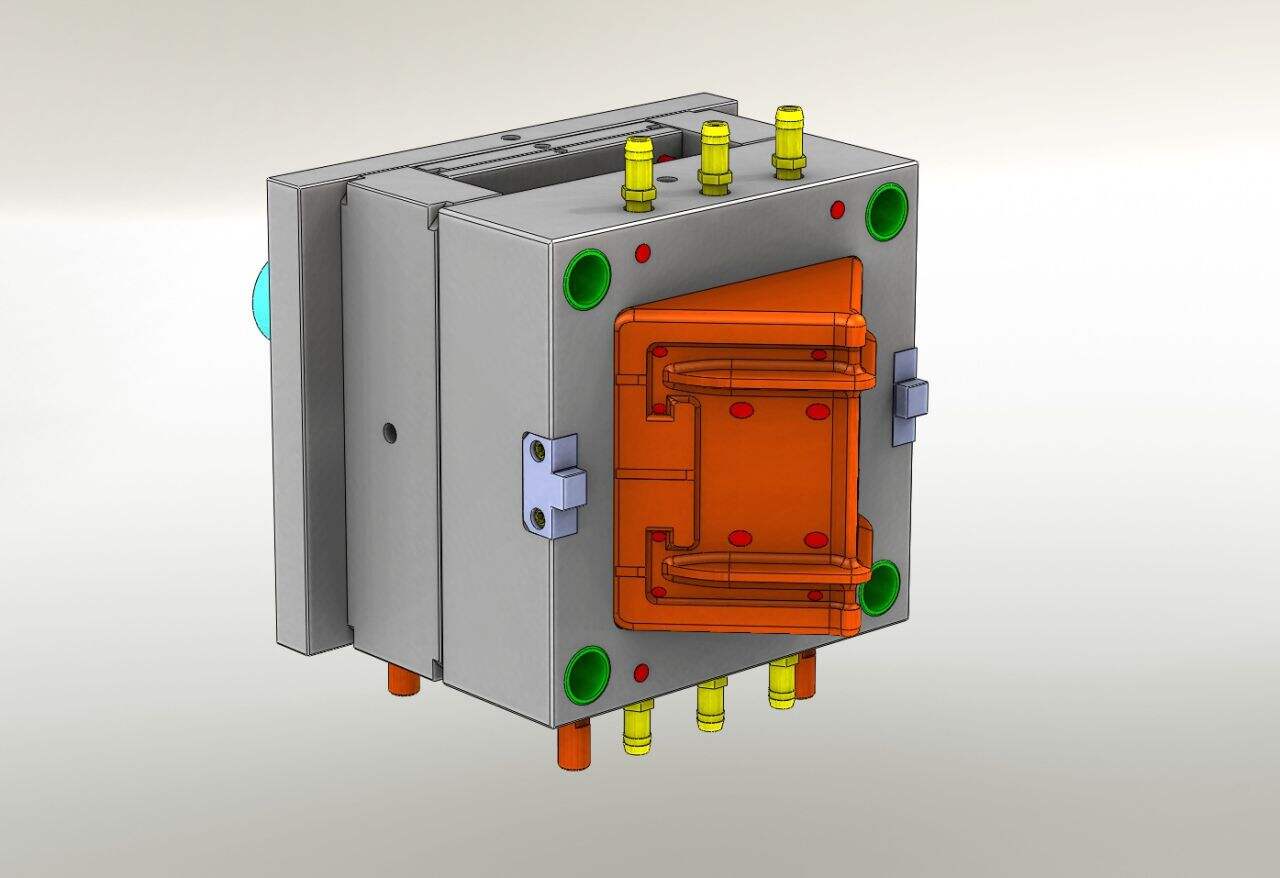

Well, what is injection molding? It’s when plastic is heated until it becomes liquid. The melted plastic is then forced into a mold. A mold is a vessel that has a predetermined form. This is what the plastic will become when cooled and set. The melted plastic goes into the mold under very high pressure. This high pressure is critical because it allows the melted plastic to completely fill every part of the mold, including those hard-to-fill little corners. Once the mold is filled with plastic, the mold is cooled down allowing the plastic to cool down and harden into whatever shape you desired.

Injection Mold plastic is an fission that has many excellent reasons to use to build plastic items than another way. One of the most significant advantages of this process is that it can produce highly detailed, complex shapes. Since the plastic gets injected under high pressure into the mold, it can get into every little detail, so that you can create products with intricate designs that would be very difficult, if not impossible to make using other methods.

CapacityNext, consider the capacity of the machine. Capacity is how much plastic the machine can hold and inject at one time. It may also be worth checking that the machine's capacity is sufficient to manufacture the quantity of products you desire. If you have to produce a lot of items in a very short period of time, you will want a machine that has a bigger capacity.

Finally, consider the features of the machine. Some machines include additional tools or functions, such as automated molds for changing products or robotic arms to assist in extracting the finished product when complete. Leveraging these additional features may help your process go more smoothly, but can also add to the price of your machine. It's important to balance the features with the cost.

Although plastic injection molding is an excellent process, it can sometimes have issues that must be resolved. One such frequent problem is when the plastic does not fill the mold completely. There are multiple reasons this issue can occur, either due to a clogged nozzle or a dirty mold itself. If it turns out the mold isn’t filling correctly, the cure is straightforward: clean the mold or use the nozzle and attempt the procedure again.

A related and even more common problem is bubbles and voids forming in the plastic. That usually occurs when the plastic cools too quickly or unevenly. To solve this, the first thing you can do is change the cooling time or temperature, so that it allows the plastic to cool evenly in the mold. By being mindful of these details, you can help avoid these issues before they start.

Mold plastic injection techniques are improving, going through a cycle of innovations and trends regularly to guarantee better final results. One popular trend at the moment is the use of bioplastics. Bioplastics are created from organic sources, such as corn or sugar cane. These natural materials are relatively more eco-friendly compared to traditional plastics, thus making bioplastics a viable sustainable alternative to manufacture products.

offer open transparent services. always seek long-term partnerships clients. Integrity foundation business relationships. Before negotiating contracts we negotiate fair prices expert advice. In mold plastic injection production We keep constant contact our customers, making sure are kept informed about process. Furthermore, we're transparent the manufacturing process, communicating updates fixing issues quickly. Customers invited give feedback any time. We developed long-lasting, solid relationships an increasing number customers through open transparent communication.

team service mold plastic injection includes pre-sales group is proficient English business communication well as engineers proficient product processing technology. We that technical sales staff collaborate facilitate efficient communication recognizing needs our customers. We our clients convenient, customized processing solutions are all-inclusive. team dedicated making your project running smoothly.

system managing orders highly efficient, scientifically-designed tool ensures prompt processing every order customers. Thanks simple order management platform, clients able submit orders quickly monitor status real-time. insist precise execution orders maintain constant communication customers during entire manufacturing process promptly address design modifications requests upgrades. Whatever size your order, approach each care, ensuring timely processing delivery top-quality results. dedication quality demonstrates commitment mold plastic injection customer expectations interactions.

We mold plastic injection ability create new projects quickly efficiently. In thriving relationship our clients quick adaptation changes design throughout process design, providing most knowledgeable advice refine sketches speed up process. We assisted clients develop thousands new products 15 years expertise custom metal processing. clients enjoyed competitive advantage thanks innovative products designed. commitment quality ensures clients get most effective solutions helps navigate competitive landscape confidence.