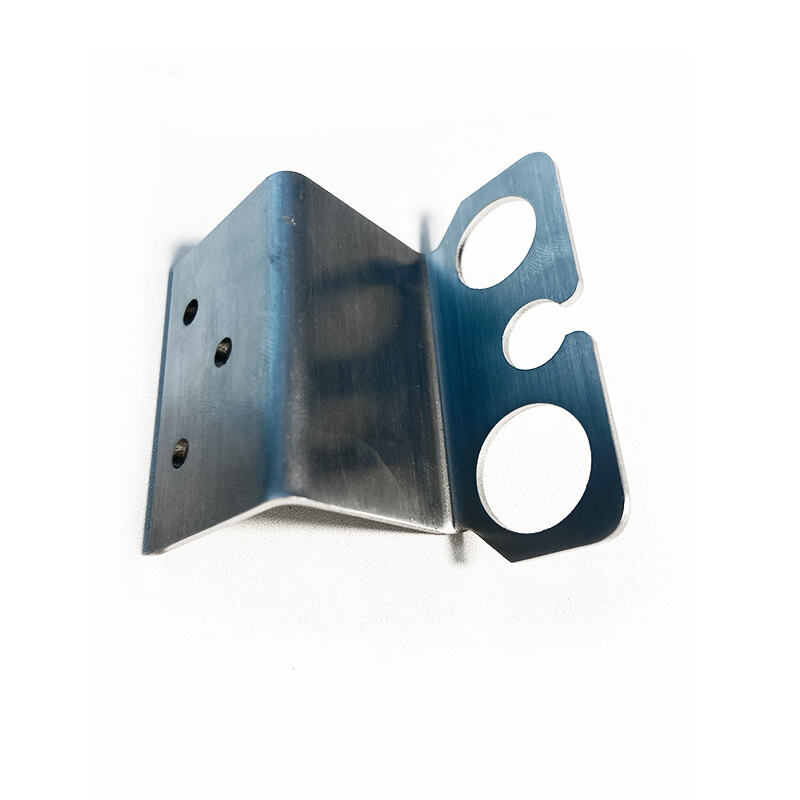

My comparison to welding might not be the best, but sheet metal laser cutting is a unique method designed for us in order to manufacture precise parts with the use of high-powered lasers. It is a hypercritical tool for creating myriad items. If there is a need to cut the sheet of metal with precision in some specific shape and size which we require for our project, then one can opt for this technology as it has many advantages. Starway sheet metal laser cutting allows us to have great products with almost no waste. That way, we can be aggressive but also prudent with our resources. Saves Time and Energy: Since the Starway laser cutting technology is able to cut metal for us, it clearly means that we are going about our work with less stress. It runs automatically — that is run by a computer. This leaves our brain to focus on other important things and the machine can go in depth with this nature.

We use industrial machines such like Starway to cut metal sheets exactly specific dimensions that we desire. We design in 3D by means of our high-tech CAD/CAM computer software which gives us the ability to model extremely accurate representations. Otherwise, it assists us in spotting errors and taking any needed steps to fix them before we cut that file. After the design is approved, it cuts perfect and intricate pieces of metal from flat sheets. Therefore it is very important that we use nothing but suitable and accurate technology to make sure our parts are flawless. This is the beauty of Starway, its excellent laser cutting helps users create a variety of components required for building any project piecemeal without compromising in quality. This allows us to consistently get excellent outcomes when we use it.

Starway's laser cutting technology is also structured in the same manner to save materials such as for welding process, making it cost-effective and providing better deals to clients. By creating less waste, it can also save the company money in material costs. This helps keep our prices competitive for the people buying your products. It also has an optimized cutting process where we could cut nearly all the metal sheets before throwing them out as scrap. If the cuts are right, Starway sheet metal fabrication makes us have less errors thus repeatable parts doesn't need to be done again. This is to keep the quality high of our products.

The fastest way to do that for us is in a laser cutting machine and Starway gets the job done fast, there are many sheets it can cut at once. With this advantage, we print more parts and the diversity of projects expanded. We are able to produce a lot of our parts fast and reliably with our own machines. This technology to up our production and releasing products quickly without losing in quality.

Laser cutting is a potent tool that facilitates the realm of manufacturing easier and reasonable. The technique of cutting sheet metal using a highly robust leading-edge computer technology is known as Laser Cutting. Starway aluminum sheet cutting techniques fit countless styles and environments for any project. It shows our flexibility, which is crucial since each customer has different requirements. One justification in favor of laser cutting is that it has less wastage and human errors which are environment-friendly methods.

service team composed team pre-sales staff are fluent English, engineers experience processing technology. We sure both technical sales personnel work together Sheet metal laser cutting design communicate effectively understanding requirements customers. offer clients efficient, custom-designed processing solutions that all-inclusive. We aware individuality every project, team make effort ensure smooth finalization project thus, achieving win-win cooperation.

offer open transparent services. always seek long-term partnerships clients. Integrity foundation business relationships. Before negotiating contracts we negotiate fair prices expert advice. In Sheet metal laser cutting design production We keep constant contact our customers, making sure are kept informed about process. Furthermore, we're transparent the manufacturing process, communicating updates fixing issues quickly. Customers invited give feedback any time. We developed long-lasting, solid relationships an increasing number customers through open transparent communication.

adeptness development Sheet metal laser cutting design projects highlighted dependable flexible capabilities. can quickly adjust changes design during design phase. close communication clients allows offer expert insight improve drawings improve speed development. Utilizing 15 years experience custom metal processing We've assisted numerous clients create thousands creative products. new products been praised marketplace providing customers advantage competition. commitment quality guarantee clients receive highest quality solutions allows navigate ever-changing market confidence.

order system advanced operates scientific efficiency, guaranteeing quick processing tracking every customer order. Through Sheet metal laser cutting design order management platform, customers effortlessly submit orders check status real-time. place high priority the precision delivery orders. addition, maintain open line communication our customers during entire manufacturing process. lets us respond swiftly requests design changes improvements. Each order handled same level attention, making sure processed promptly delivered high-quality manner. quality-focused approach demonstrates dedication surpassing customer expectations every interaction.