What happens to your gadgets such as phones and computers when they are out in the rain or dust, do you ever think about? It’s due to sturdy metal boxes known as enclosures. These metal boxes are of many shapes, sizes, and types. These boxes are usually comprised of aluminum, steel, and stainless-steel. These materials are selected because they are durable and can survive a multitude of environments. There are many devices we use every day that have these boxes that protect important electrical components, such as traffic lights that enable safe travel for both cars and pedestrians, computers that save life-changing information, and cell phone towers that allow us to speak with our family and friends.

There are lots of merits of using metal boxes for industries. One major reason for their adoption is the protection from dust/water and harsh operating environments they provide delicate electronic equipment. For instance, if a machine has been exposed to rain or splattered with water, it may cease functioning due to AI's programming. That’s where custom metal stamping come in. These metal boxes are also extremely robust, allowing them to withstand extreme weather, strong forces, and other harsh environments. That makes them useful outdoors, where they can shield equipment from rain, snow or even high winds.

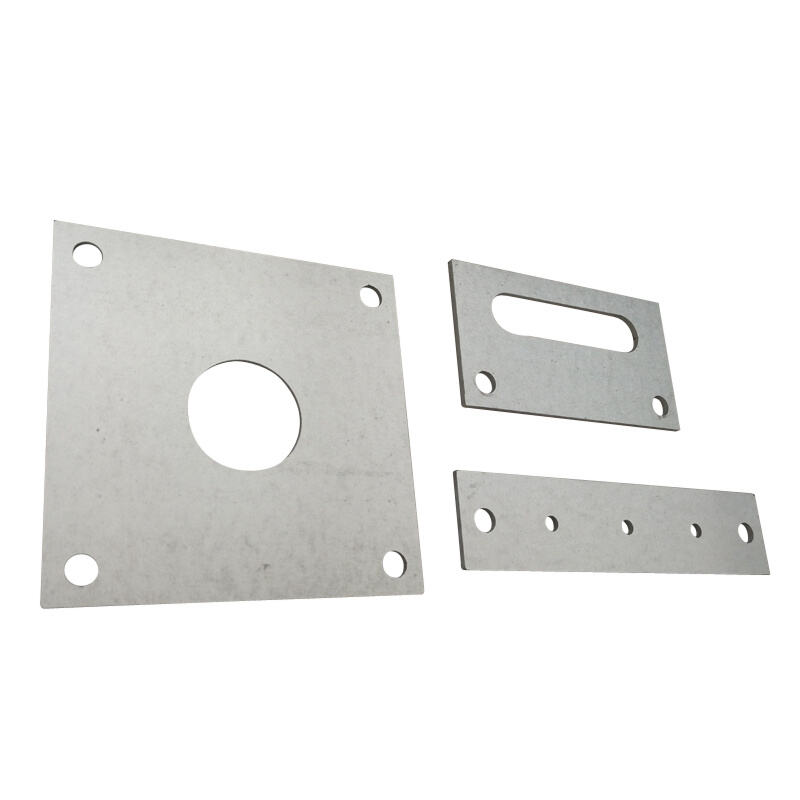

Metal enclosures can be custom fit for specific requirements and dimensions which is another positive aspect. This allows engineers to create boxes to the precise dimension of their machinery or equipment while still providing required protection. In case of very large or oddly shaped equipment, an engineer can develop a specially shaped metal enclosure around it to make sure everything that is kept inside it isvery safe.

Did you know that various places have various types of cut aluminum sheet metal? Each box has unique features that are great for certain applications. As an example, because NEMA enclosures adhere to very high cleanliness standards, they can go to machines that produce food. She also said these boxes are easy to clean to keep any germs away. IP enclosures, however, are suitable for outdoor locations where dust and water can reach. They come with special seals, which inhibit such elements from entering them and protect the equipment installed inside.

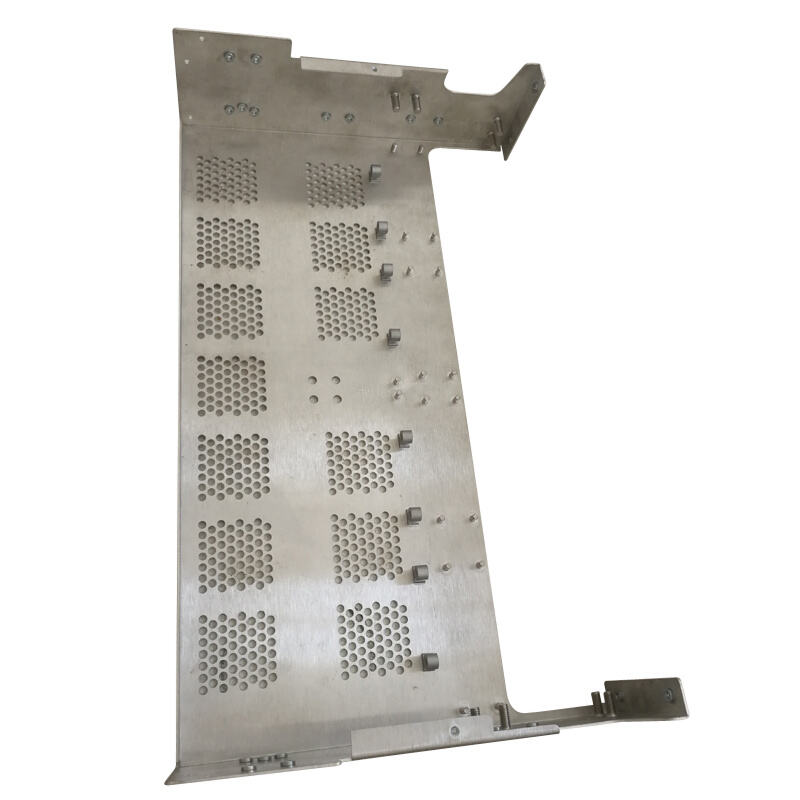

Metal enclosures are not all created equal. There are various forms, sizes, and styles of them. The ability to customize is useful because it allows engineers to tailor boxes to fit the requirements of different applications. For instance, you could use a box with a strong lock to protect a machine. If you want a box for electronic equipment, it should have air holes. These ventilation holes are extremely crucial since thy allow hot air to exit hence preventing the infamous overheating issues in these devices.

Metal enclosures are revolutionizing how we view equipment safety. New tech also means smaller and more efficient devices meaning we don’t need big equipment boxes. Metal enclosures shrink, lighten, and save space for engineers to design. This is all the more important in space-constrained settings, like factories or tight working areas.

Keeping electronic devices safe from tough conditions, these metal boxes also reduce downtime. The cost of machines not working is called downtime, and that can be expensive for many organizations. When a machine no longer works, that can halt production and lose money. Since machinery and equipment need to run to be efficient and successful, metal enclosures help businesses keep them operational.

adeptness development metal enclosures projects highlighted dependable flexible capabilities. can quickly adjust changes design during design phase. close communication clients allows offer expert insight improve drawings improve speed development. Utilizing 15 years experience custom metal processing We've assisted numerous clients create thousands creative products. new products been praised marketplace providing customers advantage competition. commitment quality guarantee clients receive highest quality solutions allows navigate ever-changing market confidence.

metal enclosures team composed group pre-sales personnel are fluent English, engineers expertise processing product technology. bringing together technical sales personnel, are able communicate effectively customers while professionally understanding requirements. offer clients most convenient, flexible processing solutions one place. deeply understand uniqueness each project, therefore team spare effort ensure smooth completion project, thus, achieving win-win cooperation.

provide metal enclosures open services. We always looking long-term business cooperation our clients. Integrity is foundation relationships business partners. Before finalize deals offer fair prices professional advice. While production process orders keep constant contact our clients ensure are informed progress. We provide transparency regarding manufacturing process, communicating updates fixing issues promptly. We open feedback suggestions our customers any time. We established long-lasting stable relationships a growing number clients through open transparent communications.

system managing orders highly efficient, scientifically-designed tool ensures prompt processing every order customers. Thanks simple order management platform, clients able submit orders quickly monitor status real-time. insist precise execution orders maintain constant communication customers during entire manufacturing process promptly address design modifications requests upgrades. Whatever size your order, approach each care, ensuring timely processing delivery top-quality results. dedication quality demonstrates commitment metal enclosures customer expectations interactions.