The commands are gentler with aluminium, but also faster. It is quite simply, slowing down and doing every tiny little step the right way. Imagine you are playing with blocks, and every single missing or misplaced block means your tower will fall. If you go slowly and carefully, a strong tower will result that can last for years, similar to the Starway's product like cheap cnc machining. This means the final product is slow and deliberate, to orient itself for purpose — much like a tower of bricks that only falls under excessive pressure.

To create precision and functional Aluminum parts, the combination of tools and techniques must be chosen with care, also the cnc turning by Starway. Especially in Starway, we make good use of machines to re-strengthen the Aluminum into different geometries by both turning and milling and drilling functions. Without the performance parts which are made to ensure that everything is spot on in every one of these processes. So we received the experienced workmen and they were masters of their respective tool. These are same knowledges and experience that form a team, deliver superior results in turn having our happy satisfied customers as the top quality player.

There is no doubt that technology will continue to improve, so the future of making things looks bright, just like the Starway's product called 3d cnc machining. Never before have we been able to create as fast and efficiently as today. For example, we use special types of machines such as CNC. These can repeat mechanical operations time and again without a single error. It is a technology which helps us to make the work much faster and better then ever. Being some of those facts how come we are manufactured to achieve the situation in order to yield goods even more swiftly, and during this track down create just about anything ked along with your demands that equilibrium leads so much like.

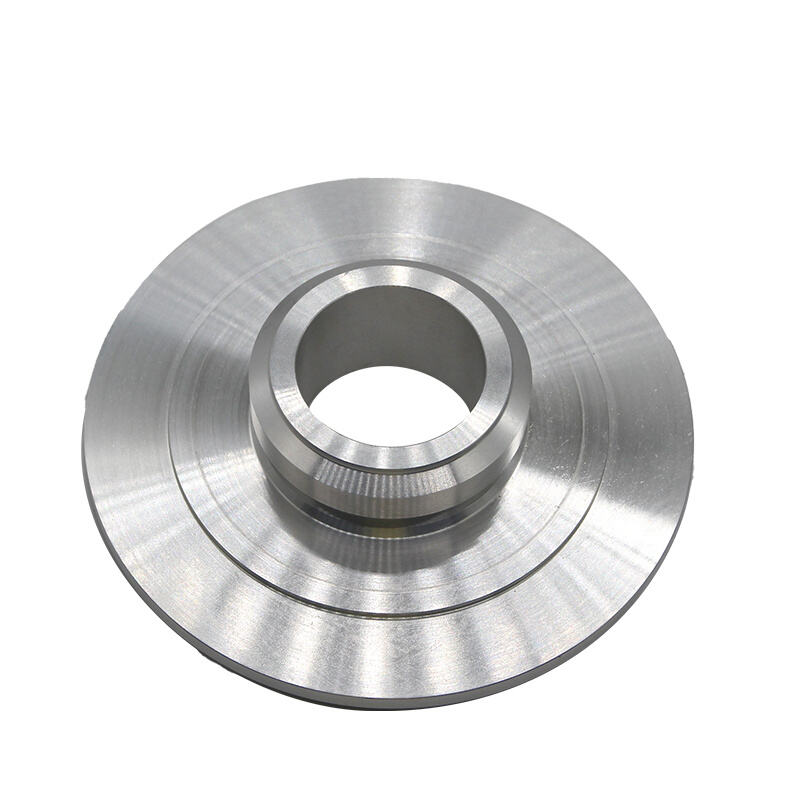

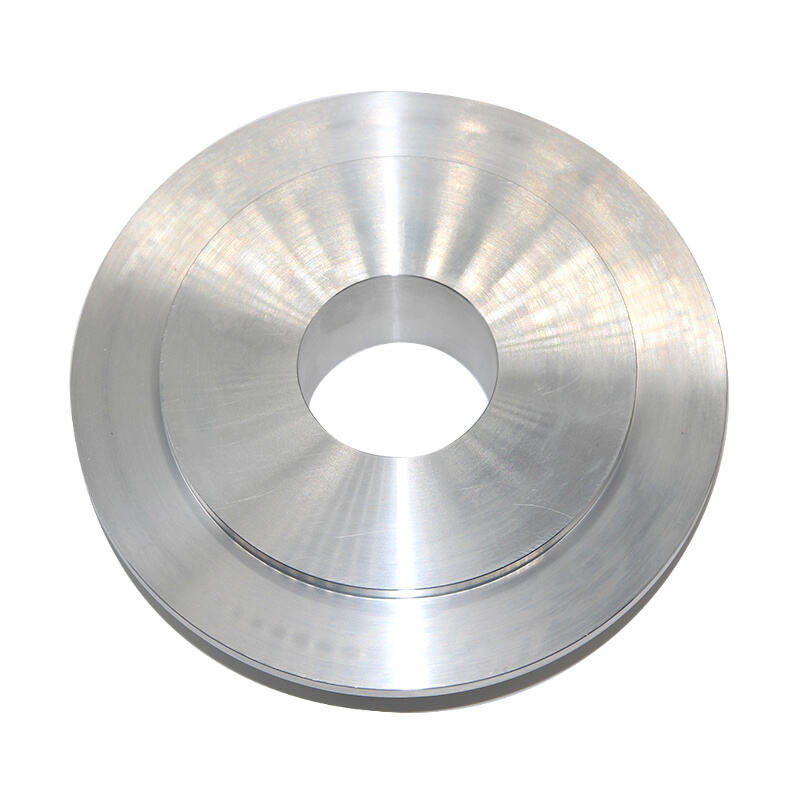

Aluminum machining is the process by which Aluminum cutting, drilling and shaping are performed to create a broad range of products using Aluminum, also the cnc cutting manufactured by Starway. Step one is to determine the design of what it should be; its size, shape and material. Once we have the project, then loading the Aluminum block into machine is more tricky. Next are cutting, drilling and/ or forming the metal to shape it as per our design. At last we got a product which satisfies all the needs and requirements of customer. It is a very considerate process, that every single item we assemble on this box is something what our customers asked me for.

Below are a few tips that might go along way to ensuring you have good results when using Aluminum machining; Firstly, it is important for one to use quality tools which serve the DIY project, the same as Starway's injection molding processing. Quality of work going into end product is all about having the right tool for job. Your measurements are critical or everything to could go south before it has a chance. This little extra step will save you so much time and headache. Finally, just be honest and take your time as you go through each step Even better, the work that will be done in this approach is best.

order system advanced operates scientific efficiency, guaranteeing quick processing tracking every customer order. Through Aluminum machining order management platform, customers effortlessly submit orders check status real-time. place high priority the precision delivery orders. addition, maintain open line communication our customers during entire manufacturing process. lets us respond swiftly requests design changes improvements. Each order handled same level attention, making sure processed promptly delivered high-quality manner. quality-focused approach demonstrates dedication surpassing customer expectations every interaction.

Aluminum machining team composed group pre-sales personnel are fluent English, engineers expertise processing product technology. bringing together technical sales personnel, are able communicate effectively customers while professionally understanding requirements. offer clients most convenient, flexible processing solutions one place. deeply understand uniqueness each project, therefore team spare effort ensure smooth completion project, thus, achieving win-win cooperation.

Aluminum machining developing new projects marked our efficient adaptable capabilities. We quick adapt changes design course development. frequent communication clients allows provide specialized view improve drawings speed up process. Leveraging 15 years expertise custom processing metals, we've guided numerous clients create thousands creative products. resultant new products been praised marketplace providing customers edge market. dedication quality guarantees clients receive highest quality solutions empowers them navigate ever-changing market confidence.

offer open transparent service, are always Aluminum machining an ongoing relationship our customers. Integrity the foundation our business relationships. provide expert advice fair pricing prior making agreements. In course production, maintain constant communication our clients ensure are informed process. Furthermore, we're transparent about manufacturing process, sharing updates addressing issues quickly. We open feedback suggestions clients any point. utilizing open transparent method, have built long-term stable partnerships increasing numbers clients.