Polymeric carbonate is a unique type of plastic so the reason is used to create other common objects. A common method of product creation using polycarbonate is through a process known as injection molding. The process of injection molding starts with melting down the plastic to a gooey state. The next step is to melt it, then force it into a mold, a hollow form that depicts the shape of the final product. You can use this process to generate a large number of items very quickly and very easily.

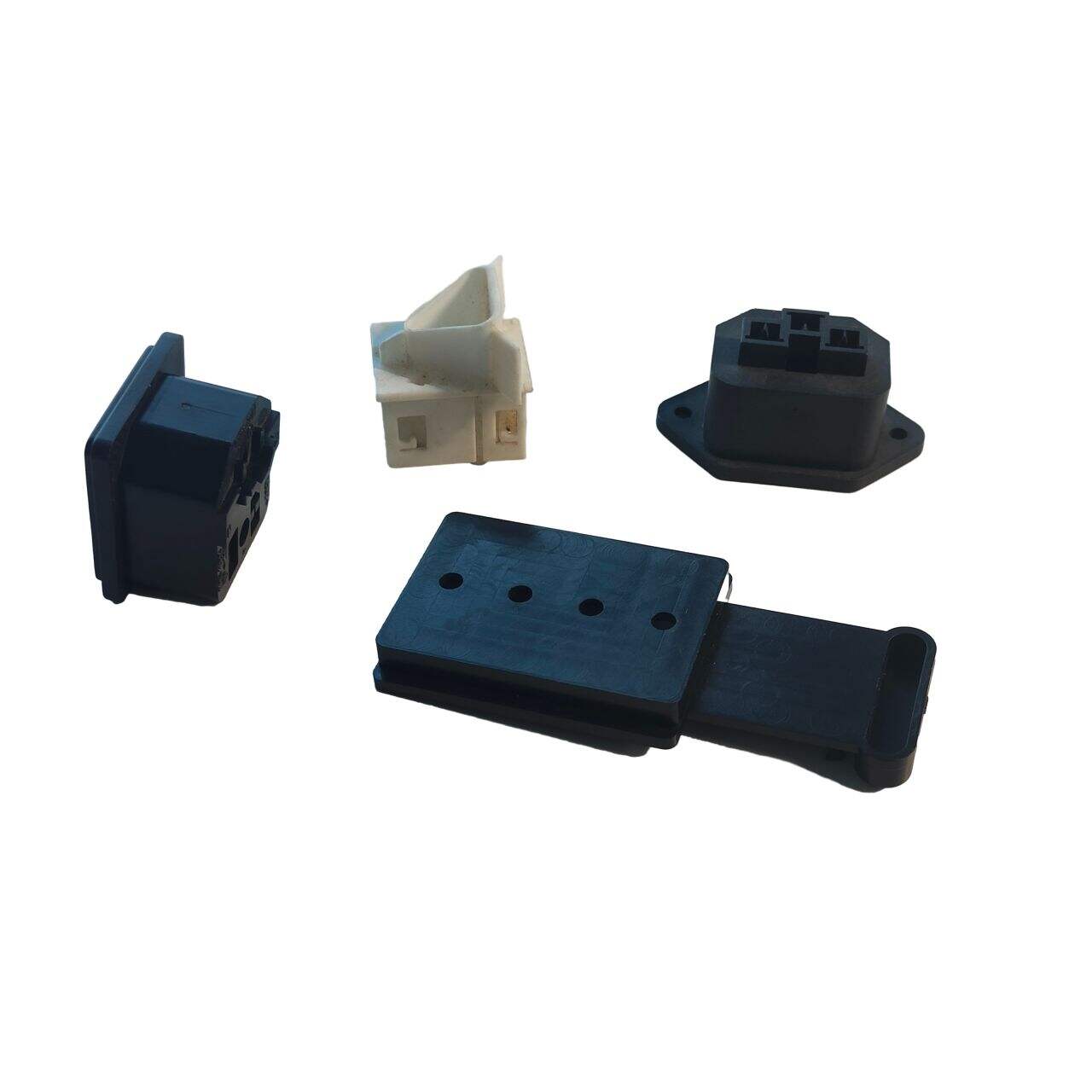

Polycarbonate is referred to as a thermoplastic material that is injected to form solid polycarbonate polymerized components. Polycarbonate is a durable material, and thus, can withstand considerable wear and tear. It is ideal for creating items that people will use completely over and over and over again without breaking. This process is applied in many different ways — most notably, we have phone cases that serve as protective shells for our devices, car components that allow for integrated performance in the streets, and glass window panes from which you can confidently look at the sky (or the ground, unfortunately) when you’re in the air.

Moreover, complex shapes can be obtained rather easily using cnc machining, which is another benefit of this process. Because the plastic gets injected into a mold, it can share any design that’s needed. This implies that complex and detailed featured products can be created with less work and greater expediency. Moreover, items manufactured using this procedure have superior finishes. They look very smooth and shiny; it matters to customer satisfaction.

Polycarbonate injection molding is also economical for product manufacturing. Since its process is swift, products are produced fast, and less manpower is needed. This helps limit costs for businesses. In addition, this method enables the production of multiple products simultaneously, leading to even lower costs. This is particularly advantageous for firms that require rapid production of high volume goods. Especially for those businesses low on budgets, saving costs, and making quality products is a win-win situation.

Just as polycarbonate injection molding is also environmental friendly. This is partly because polycarbonate products are robust and durable. If things last longer, we don't have to replace them as frequently, resulting in fewer resources used. Polycarbonate is also recyclable, which is a big plus. Polycarbonate can be recycled by melting down and making new polycarbonate products out of it. This process aids in diverting waste from landfills and assists in protecting our planet.

Selecting the right type of polycarbonate resin and any additives is an important step in polycarbonate injection molding. Resins are the base materials that comprise the plastic; additives are specialized compounds that drive enhancements of the plastic’s properties. These additives can strengthen the plastic, make it more flexible or better able to withstand heat. With the right blend and balance of resins and additives, manufacturers can enhance the quality of their end products.

Starway provides polycarbonate injection molding. You know that polycarbonate is a great option when considering several aspects of it as a material. We can assist you in selecting the appropriate blend of resins and additives that best fits your product specifications. Our experts will help you create quality, strong, durable, and economical products meeting your requirement.

team service professionals includes pre-sales staff who fluent English business communications, engineers skilled processing product technology. bringing together sales technical staff, ensure efficient communication our customers, while understanding requirements. offer clients polycarbonate injection molding, custom-designed processing solutions one stop. understand specificity each project, therefore team spare effort ensure smooth finalization your project achieving win-win cooperation.

polycarbonate injection molding management system efficient tool scientifically designed ensures speedy completion every order placed customers. order management system permits customers easily submit orders track status real time. prioritize precise processing orders keep regular communication customers throughout process manufacturing, promptly addressing modifications design upgrades requests. No matter large order approach every order meticulous attention, ensuring timely processing orders superior results. commitment excellence evident dedication meeting exceeding customer expectations every step of way.

We renowned capacity create new projects swiftly efficiently. With strong emphasis communication clients, we promptly adapt product design alterations throughout process development, provide expert insights refine sketches speed up process. Leveraging 15 years expertise custom metal processing design, we've helped numerous customers creating thousands unique products. customers benefited advantages competition thanks new products that have created. commitment quality makes sure clients receive best solutions helps polycarbonate injection molding competitive landscape confidence.

offer polycarbonate injection molding transparent service, are always looking long-term relationships our clients. believe honesty is cornerstone of partnership our customers. provide expert guidance fair pricing prior making agreements. keep constant contact our clients throughout process production so they aware. also provide transparency about manufacturing process, giving updates responding any issues promptly. We open feedback suggestions customers any time. Through open transparent approach, have forged steady long-term partnerships increasing numbers customers.