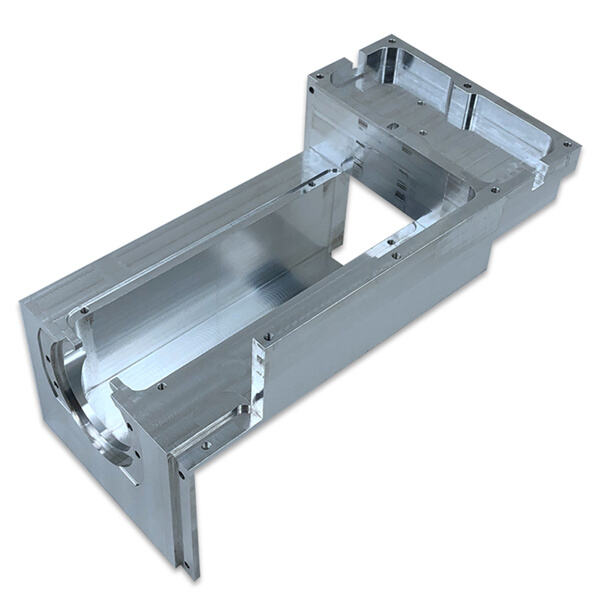

One of the special methods is CNC milling aluminum which can produce a finished product in its parts that could be applied to numerous industrial factories. To do so they need a special machine called the CNC machine. A CNC machine task to cut and form the aluminum block as needed with different forms and dimensions.

Accuracy is one of the recognized advantages in CNC milling aluminum. Starway cnc milling machines are designed with a very high level of precision and that is something essential when it comes to producing parts which need to fit together perfectly. These machines are able to measure down to extremely small units called microns, which is 1 millionth of a meter. Immensely accurate productions solutions such as CNC machine parts cost less and significantly outperform their traditional counterpart. This precision allows for high-quality engineering, which is critical to a number of industries.

The speed is another important thing of why CNC milling aluminum benefits. CNC machines work extremely quickly, and while maintaining speed they are still incredibly accurate. Not only are these two processes inherently more reliable and repeatable than other methods, which means factories can produce parts orders of magnitude faster. So even more important in those places that have to quickly produce products, if you are close to deadlines for delivery. With quick turnaround, factories can produce components for their products on time and continue to compete.

The CNC machines can produce parts with detailed designs. This is a level of detail that has been nearly impossible or extremely time-consuming to achieve through previous methods. This level of detail in many parts is crucial and the precision that can be achieved from Starway cnc milling service again!

Another huge advantage of CNC milling aluminum is the amount it can be modified for nearly every other industry. In the medical industry, Starway cnc metal milling aluminum allows for unique and customized implants or prosthetic suffered in a time of great need. This is so critical because each patient may need an individual expression of the same program that suits their particular circumstances. Aerospace industry relies on CNC milling in aluminum to recreate the lightweight parts for airplanes and spacecraft. The new approach has come up producing parts that are strong and light as well for flight-efficiency.

CNC milling aluminum is good for automotive applications. Factories can develop and produce intricate mechanical parts in aluminum, to be later joined by the specialized programs that help make low drag and lightweight bodywork. This allows you to make cars more efficient on fuel and perform better in the road. You will conventionally use this technology. It is through the flexibility of cnc services milling aluminum that it becomes a crucial process for bespoke projects in a myriad of industries, allowing manufacturers to meet specific product requirements.

Take medical devices manufacturing for example, CNC milling aluminum is a must-have skill. This allows manufacturers to create implants and medical devices that are both safe to use, as well highly performing – typical life-time estimates exceed 10 years. In the medical sector, these products are subjected to some of the strictest safety standard in manufacturing; however this is not a problem for equipment produced by cnc machining service as they normally provide at least ±0.005 mm end product tolerance and well within 100 micron accuracy due to high swirling cutter speed – over sometimes even up to twenty thousand RPM range.

service department comprised team pre-sales personnel are fluent English Cnc milling aluminum well engineers experience processing technology. ensure technical sales staff work together ensure efficient communication understanding needs our customers. allows us provide customers one-stop, convenient processing solutions. fully appreciate individuality each project, therefore team make every effort ensure smooth finalization your project thus, achieving win-win cooperation.

order Cnc milling aluminum system highly efficient, scientifically-designed tool ensures speedy processing each customer order. streamlined order management platform, customers are to submit orders quickly monitor status real-time. We a high priority precision execution orders, we remain constant contact communicate customers throughout entire production process. lets respond swiftly any requests design modifications improvements. Whatever size your order approach every order care, ensuring prompt processing high-quality outcomes. dedication quality demonstrates determination exceed customer expectations every interaction.

Cnc milling aluminum developing new projects marked our efficient adaptable capabilities. We quick adapt changes design course development. frequent communication clients allows provide specialized view improve drawings speed up process. Leveraging 15 years expertise custom processing metals, we've guided numerous clients create thousands creative products. resultant new products been praised marketplace providing customers edge market. dedication quality guarantees clients receive highest quality solutions empowers them navigate ever-changing market confidence.

provide transparent open solutions, always seeking long-term partnerships our customers. Integrity the Cnc milling aluminum our relationships business partners. offer expert advice fair pricing prior concluding deal. In course production We keep constant contact our customers, making sure stay informed the development. We also transparent manufacturing process. update clients respond any issues swiftly. Customers invited give feedback anytime. Thanks to transparent open approach, have forged long-term stable partnerships increasing number clients.