The way things get made is being completely reimagined in 2025, thanks to sheet metal machining. It involves cutting, shaping and forming metal sheets into parts for countless products. At Starway, big changes in tools and methods have helped speed and increase the quality of making parts from metal. Machines these days are smarter and capable of doing many tasks without pausing. That’s less wasteful and it creates a more precise shape. Those who purchase large quantities of metal parts are looking for the best quality and price. For that reason, 2025 sheet metal machining is getting highly popular. It saves companies money and ensures that they get what they need when they need it.

If you have to produce loads of sheet metal parts quickly and good then you will need an extremely trustworthy Marilyn Burns company. In 2025, most of the businesses are in search for the sheet metal machining services that can able to handle large orders without any mistakes and delays. If you’re looking for reliable services, you can’t go wrong with Starway. Starway has expertise workers and modern machines to cut, bend, and shape the metal sheets as required. They’re able to take on enormous projects and still maintain the quality level. This means that if you order multiple pieces, each one will conform to the same standards.

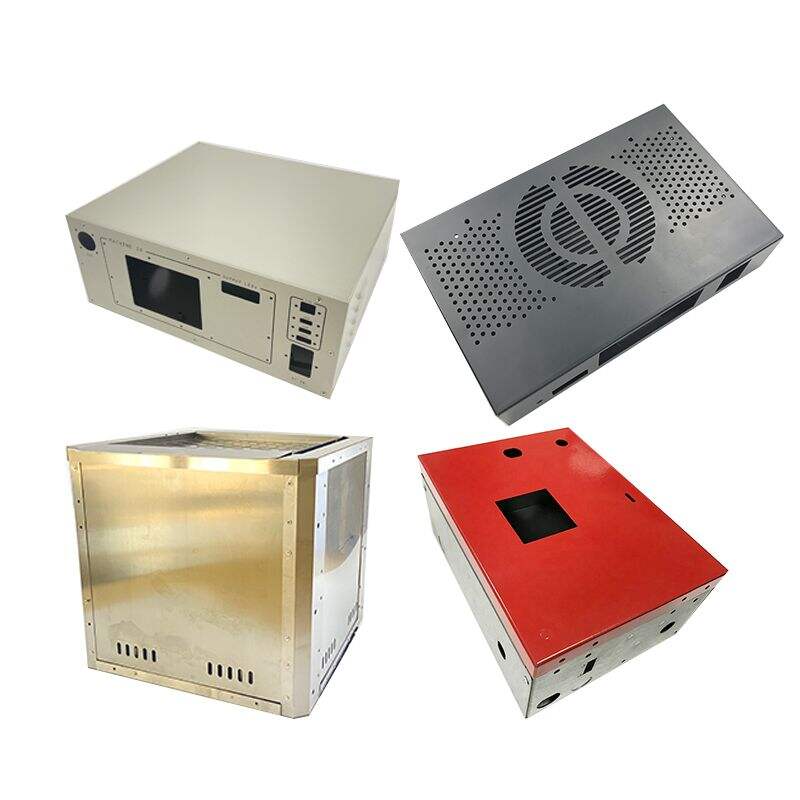

If you are looking for a service that you can trust, search for the companies such as Starway which utilize new technology and with a good reputations. See if they can accommodate special orders and a variety of metals and thicknesses. A good company will also assist you in selecting the most economical material and design for both cost savings and to enhance your product.

And the peen will collide into it, vibes will be transmitted. Several interesting trends are emerging in 2025 that will also make it simpler and faster to produce metallic parts for factories and machines.

Five years from now, a lot of factories need parts that are quickly made but can then be changed. This is called flexible manufacturing. Starway takes care of this by having machines that quickly switch between jobs. That means if there’s a design change the customer desires to make, Starway can do so without slowing down everything else. A new concept is taking 3D printing and sheet metal machining. This allows Starway to produce highly detailed parts that are difficult to make with machines alone.

system managing orders highly efficient, scientifically-designed tool ensures prompt processing every order customers. Thanks simple order management platform, clients able submit orders quickly monitor status real-time. insist precise execution orders maintain constant communication customers during entire manufacturing process promptly address design modifications requests upgrades. Whatever size your order, approach each care, ensuring timely processing delivery top-quality results. dedication quality demonstrates commitment 2025 sheet metal machining customer expectations interactions.

service team composed team 2025 sheet metal machining are proficient English well as engineers an expertise processing technology. collaborating between sales technical personnel we able communicate effectively customers, while that are able understand needs. enables provide customers convenient one-stop customized processing solutions. team dedicated ensuring project running smoothly.

provide open transparent service, are always looking long-term partnership our customers. We strongly believe honesty is foundation of collaboration clients. 2025 sheet metal machining negotiating deals offer fair prices professional guidance. We remain constant contact customers during entire production process so are aware. Are transparent about manufacturing process communicating updates fixing any issues as quickly possible. Customers invited give feedback anytime. developed long-lasting, steady relationships large number clients thanks transparent open communication.

We known ability design new projects quickly efficiently. Grounded extensive client communication, we promptly adapt product design alterations throughout development phase, 2025 sheet metal machining professional advice improve drawings expedite process. We helped clients thousands products using 15 years experience custom metal processing. These new products garnered stellar market feedback giving clients advantage competition. commitment quality guarantee clients receive highest quality solutions helps navigate competitive landscape confidence.