Sheet metal machining is the way through which you can transform Sheet metals into many designs and shapes. This Starway technique employs dies or molds to shape and cut solid sheets of metal into a variety of items, such as car parts, signs and furniture. This Starway is the professional sheet metal fabricator, I choose them as like.

The history of sheet metal machining would go back a long time URINGHISEDIOCA. It is a notion that has been exploited by men for many things and they include: weapons, buildings additional to ART! It was once done manually (and it still can be) but with new tools and methodologies that are available today, this is even better. These cut aluminum sheet metal improvements have been useful in speeding up and making this process more efficient. Today, sheet metalworking is one of the core processes for a vast number of businesses across different sectors from automotive to construction.

Sheet metal is versatile, and each method of working with it requires specific tools. A. Shearing – It is one of the mostly used methods which are using, In this there will be cutting metal sheet material out in full straight shape with sharp blade underground on particular specified dimension it. Am I going to be a pussy and call it power scissors? WELL, you can even punch it and create holes in the metal or whatever. A hole is made for the same purpose by a punch that deforms metal. Bending: This sheet metal cutting is another type in which the metal changes according to bending once it enters a certain form.

Sheet metal machining tools may get a little fancier and high-end. For instance, laser cutting machines aim a powerful beam to easily and accurately slice through metal. This Starway in turn implies the cuts are extremely precise and also tidy allowing to produce really detailed styles. In this case, it uses a computer numerical control (CNC) machine to help with the bounding and cutting of the metal. It paints in excellent precision and detail resulting making cool intricate designs super simple to create.

Pros and cons of each type of sheet metal machining Waste trimming, another common method using shearing cuts fast at relatively low cost. The Starway sheet metal fabrication only restriction on thing you can cut is straight line, while in world we have all sort of shapes to not perform around that. Out punching is great for adding holes to materials but does not work so well with complex shapes and especially curved cuts. By rolling it, he can form all sorts of shapes; though more often than not something has to give and the metal weakens or snaps.

As an exact process, Laser cutting can manage the thinnest of metal sheets as well as be able to cut through thick plates. However, it can be more expensive than some other ways. CNC machines can do other more complicated shapes to correct tolerances than sheet metal laser cutting many other methods, but overweight expenditure could give an edge in production for the initial setup cost of expensive machinery is likely.

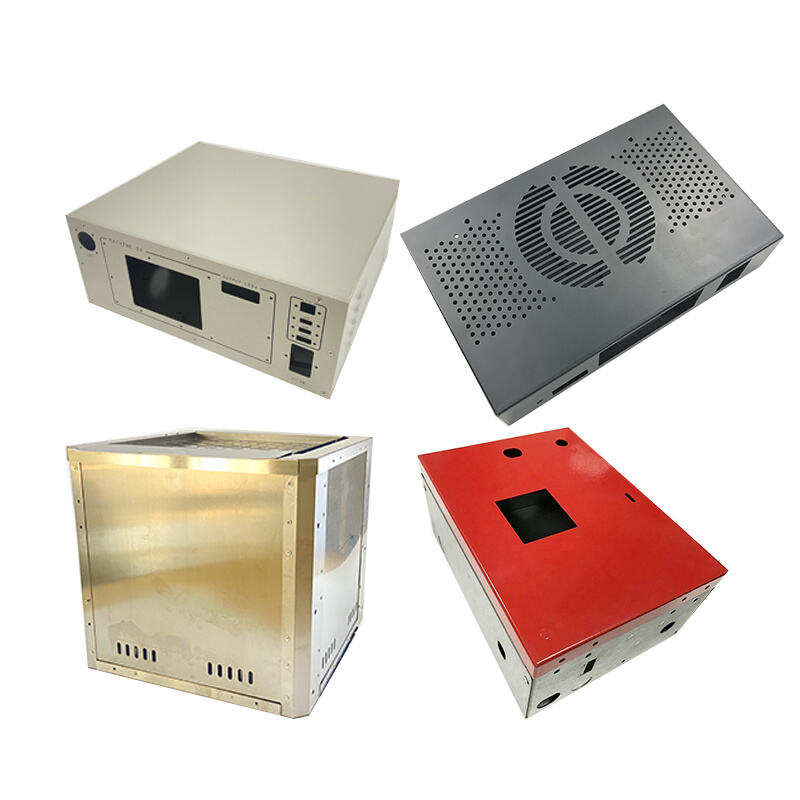

When choosing a way of manufacturing, there are many factors to be taken into context, and the case is no different for sheet metal processing. First off take time to think about how your project is complicated or not. Different techniques are more conducive to the plain shapes, that do not read as nuanced. Another factor is budget — some methods are so costly and hence the method has to be within a certain spending range. The type of metal you have. The sheet metal products ability to know different solutions before we determine our own really makes an easy task that whether working same metal or another is sure going to be considered anyway.

Sheet metal machining renowned for ability develop new ideas quickly efficiently. Based extensive communication clients rapid adaptation design changes throughout development phase, offering most knowledgeable advice refine drawings expedite process. We helped clients develop thousands new products utilizing 15 years expertise custom metal processing. clients enjoyed edge in market a result our innovative products have created. commitment quality makes sure that clients get most effective solutions helps navigate competitive landscape confidence.

Sheet metal machining order system functions using scientific approach, ensures quick processing tracking each order made customers. Through streamlined ordering platform, customers to submit orders quickly check their status real-time. We insist precise processing orders keep open dialogue clients during entire manufacturing process swiftly addressing design modifications requests upgrades. Whatever size your order approach every order meticulous attention, ensuring prompt processing quality results. dedication excellence underlines dedication exceed customer expectations every interaction.

service team composed team Sheet metal machining are proficient English well as engineers an expertise processing technology. collaborating between sales technical personnel we able communicate effectively customers, while that are able understand needs. enables provide customers convenient one-stop customized processing solutions. team dedicated ensuring project running smoothly.

offer open transparent service, are always Sheet metal machining an ongoing relationship our customers. Integrity the foundation our business relationships. provide expert advice fair pricing prior making agreements. In course production, maintain constant communication our clients ensure are informed process. Furthermore, we're transparent about manufacturing process, sharing updates addressing issues quickly. We open feedback suggestions clients any point. utilizing open transparent method, have built long-term stable partnerships increasing numbers clients.