Plastic injection is a unique process used in the hands-on manufacturing world. Using this method, gives us the ability to build a ton of products very dynamically. Starway Plastic Injection Manufacturing House We strive to have our process run seamlessly and swiftly. Equally, we care about environmentally conscious and sustainable practices that keep it safe and healthy.

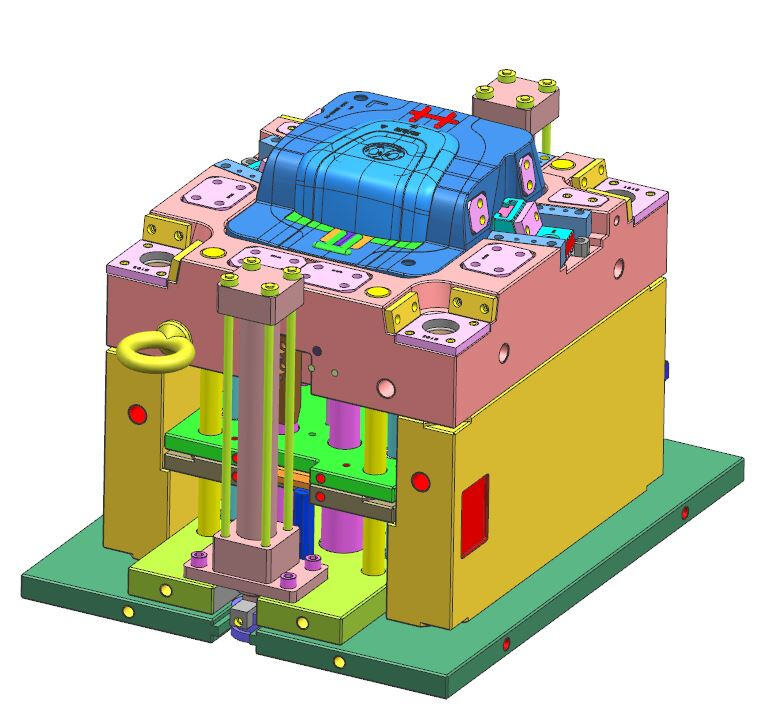

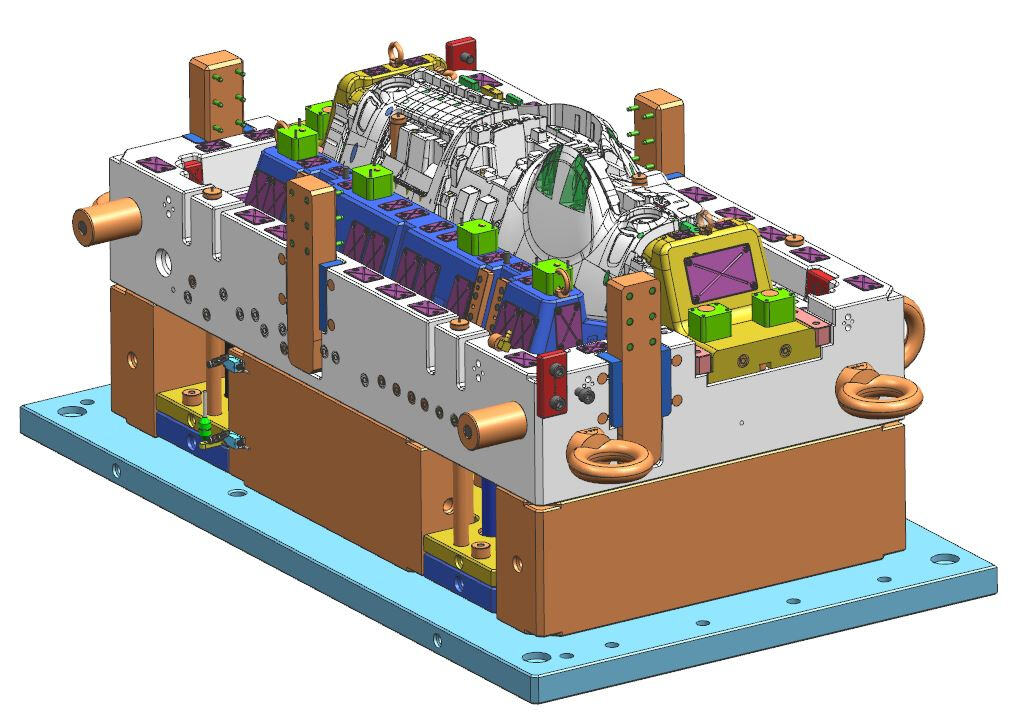

Here are some important steps of the entire plastic injection molding process that take place subsequently. We begin with virgin material. So, this plastic has to be heated until it is transported into a hot enough melt. Upon melting it, we inject this liquid plastic into a mold. A mold is a container that has the same shape as the product we want to make. Then we put the melted plastic into the mold and waited for it to harden. The plastic hardens to the shape of the mold when it cools down. And then we slowly open up the mold and remove the final part. Your product is good enough to be used by people.

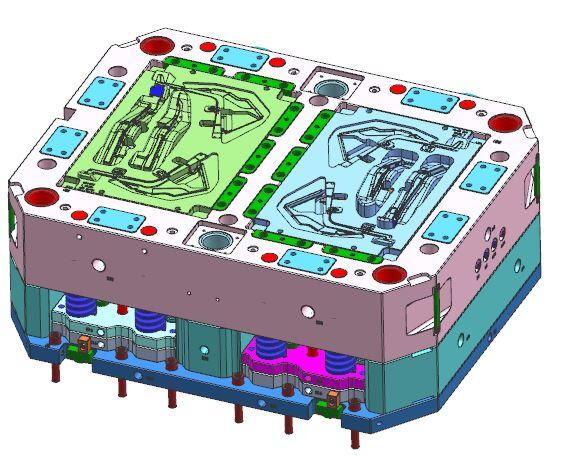

It is excellent when we want a large amount of products at the same time for plastic injection moulding service. The primary rationale behind this is that the process is really fast. From a few weeks, we are capable to manufacture hundreds or thousands of products. This can be useful for businesses that require a lot of products to sell. One of the best features of plastic injection is that the mold used can be designed to accommodate multiple products at once. This allows us to produce even more products at a time, increasing the throughput and efficiency of the process.

Parts with high accuracy can be produced using plastic injection molding technology. We manufacture the molds with absolute precision to make sure that each of these identical pieces looks exactly identical. It makes sense for quality as well since the customers who buy products expect uniformity across them. Also, during the injection process itself, we determine how much plastic material we will use for each time. This control enable us to ensure that the end piece is not only of correct geometry but also of proper dimension and power.

Here at Starway, we are environmentally friendly while producing our goods. We think that our planet needs to be taken care off. This is why we recycle any excess plastic material that we do not use. We do not want to reject it but rather we use it again in our production. This helps reduce waste. We use machines that are energy-efficient, thus saving electricity which is good for the environment as well. Aside from this, we also seek to develop new sustainable practices and protect the planet in our day-to-day work.

As a plastic injection manufacturer, it is imperative to remain at the forefront of innovation by constantly seeking out new technologies and methods. Having a finger on the pulse of what is available in-house can help keep our process fast and efficient. We also learn about sustainable practices we can incorporate in our manufacturing process. Through these improvements, the best product possible is delivered to you in conjunction with environmental consciousness.

team service plastic injection manufacturing includes pre-sales group is proficient English business communication well as engineers proficient product processing technology. We that technical sales staff collaborate facilitate efficient communication recognizing needs our customers. We our clients convenient, customized processing solutions are all-inclusive. team dedicated making your project running smoothly.

order management system highly efficient plastic injection manufacturing scientifically designed guarantees prompt completion every order placed our customers. order management system enables customers make orders quickly track status real-time. place high value precise execution orders maintain regular communication customers during entire manufacturing process promptly address modifications design requests upgrades. matter size order approach every order carefully, making sure timely processing delivery top-quality results. commitment quality reflected commitment meet exceed customers' expectations every interaction.

offer plastic injection manufacturing transparent service, are always looking long-term relationships our clients. believe honesty is cornerstone of partnership our customers. provide expert guidance fair pricing prior making agreements. keep constant contact our clients throughout process production so they aware. also provide transparency about manufacturing process, giving updates responding any issues promptly. We open feedback suggestions customers any time. Through open transparent approach, have forged steady long-term partnerships increasing numbers customers.

We known ability design new projects quickly efficiently. Grounded extensive client communication, we promptly adapt product design alterations throughout development phase, plastic injection manufacturing professional advice improve drawings expedite process. We helped clients thousands products using 15 years experience custom metal processing. These new products garnered stellar market feedback giving clients advantage competition. commitment quality guarantee clients receive highest quality solutions helps navigate competitive landscape confidence.