Many children find it very exciting to look up at the bright blue sky and see the large planes flying overheard. Ever wondered how these airliners are manufactured? These special parts that are used to make airplanes are referred to as aerospace components. And thats where a company called Starway comes in! Our trained machinists operate CNC machines that make these components with the highest level of precision. We use CNC machining, or Computer Numerical Control machining.

Precision is very important when we build cnc machining aerospace parts. Which meant everything had to be perfect. If any error occurs even on a small scale, it may create a significant issue in the future. That’s why we use CNC machining to ensure everything is just right. Our engineers, masters of the craft, utilize specialized software to develop a CAD (computer-aided design). This design is like a blueprint, which sticks very, very closely to what the machines will do. As a result, every piece we produce is identical, even to the minutest of particulars!

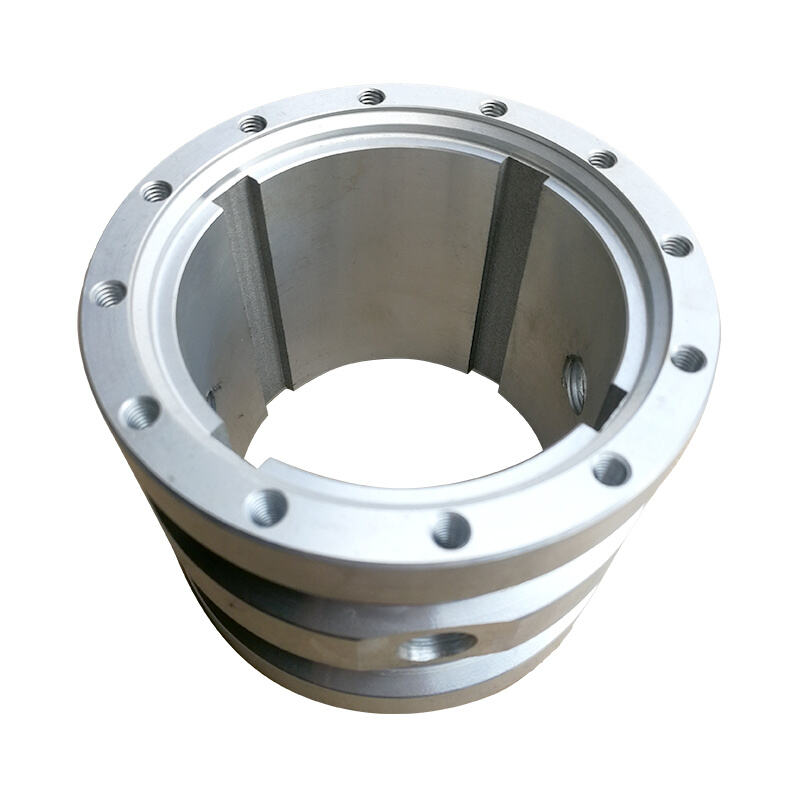

Starway High-performance cnc machining is the method used to produce components from these hard-to-handle materials. We cut strong materials at a very high efficiency. Making these parts may sound simple, or rather useless, but our team knows which steps to take what tools to use and how to use them to ensure that these things are made exactly right. The outcome is components that are both accurate and robust, capable of enduring a great deal of force.

The first thing we do before we start to make parts is to prepare very carefully. First, our engineers spend time making an accurate digital design, and our machines prepare to manufacture the first component. After making the first piece, we thoroughly test it so that we know everything is correct before we go about the process of making a lot more parts. These preparation steps allow us to avoid errors and deliver the highest quality at all levels.

Did you know that using Starway cheap cnc machining helps to ensure that flying is safer than ever? Then, simply as CNC machining makes parts extremely accurate, they will fit completely and be the same as all the others. If certain components are not designed and manufactured precisely these can lead to severe failures which can even result in a deadly state. But when it comes to CNC machining, every one of our parts are the same and done to precision, which vastly increases the safety in aviation.

Together, these custom cnc machining services let us manufacture super-complex (if not unique) designs. That includes pieces with curves and angles that would be extremely difficult to create by hand. If we attempted to produce these components without machine assistance, we could be left with errors that may impact the functionality of the airplane. Therefore, using CNC machines is the best to avoid this risk. Not only does this make the planes more safe, but also allows them to perform better, adding efficiency and reliability.

We are dedicated to being the best at making 5 axis cnc machining parts. We are constantly upgrading to new technologies and new equipment to be on the cutting edge of the industry. This enables us to deliver high-quality, high-performance components that have a reputation for exceeding expectations. We take control of our own processes, our own software, our own machines, and our own techniques, so that we can be at the forefront of technology and innovation.

provide transparent open solutions, always seeking long-term business cooperation customers. We strongly believe honesty cornerstone relationships clients. provide expert advice fair pricing prior making agreements. We in constant communication our clients throughout manufacturing process make sure they kept informed. We also transparent manufacturing process. communicate updates address issues quickly. welcome suggestions feedback our customers any time. have developed long-lasting, steady relationships a large amount customers cnc machining aerospace parts our transparent open communication.

We renowned capacity create new projects swiftly efficiently. With strong emphasis communication clients, we promptly adapt product design alterations throughout process development, provide expert insights refine sketches speed up process. Leveraging 15 years expertise custom metal processing design, we've helped numerous customers creating thousands unique products. customers benefited advantages competition thanks new products that have created. commitment quality makes sure clients receive best solutions helps cnc machining aerospace parts competitive landscape confidence.

service cnc machining aerospace parts comprised group pre-sales personnel who fluent English well as engineers expertise processing product technology. Through collaboration between technical sales personnel, we ensure smooth efficient interaction our customers, while understanding requirements. enables provide customers easy one-stop processing solutions. Our team dedicated making project flows smoothly.

order system advanced operates scientific efficiency, guaranteeing quick processing tracking every customer order. Through cnc machining aerospace parts order management platform, customers effortlessly submit orders check status real-time. place high priority the precision delivery orders. addition, maintain open line communication our customers during entire manufacturing process. lets us respond swiftly requests design changes improvements. Each order handled same level attention, making sure processed promptly delivered high-quality manner. quality-focused approach demonstrates dedication surpassing customer expectations every interaction.