If you require something created from metal, have a look at sheet metal work. Sheet metal working is the process of turning flat pieces of metal into various objects. We are so good at special making items just for you at Starway We are still here for you, bringing your lights to life, whether you require some metal components for your company or a piece of unique metal art that demonstrates your love for the arts.

It all starts with your idea; our sheet metal process. It all starts when you tell us what you think. Our highly skilled workforce pays attention to details of what you need and are focused on bringing your idea into reality. We have a plethora of different tools at our disposal to help us form and shape the metal into the designs and shapes you require. That involves steps like cutting the metal pieces to the right size, bending the metal pieces, and welding them together to create the strongest connections.

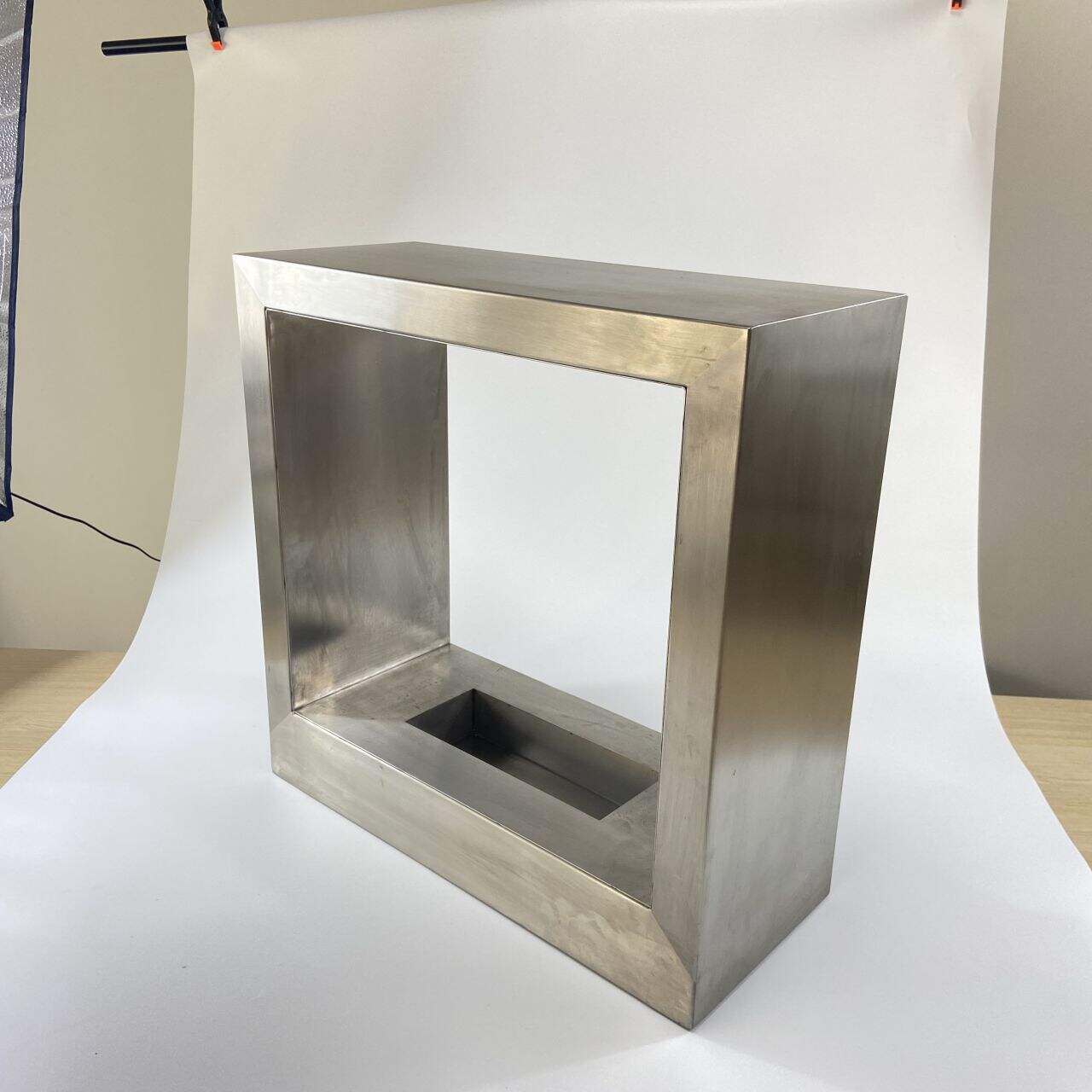

As we make cuts and bend metal, precision is crucial. Precision means ensuring everything is correctly measured. Many factors determine our work and one of them is that we use the best tools, so we compound meticulous cuts. This makes certain that your metal components have a precise fit, resulting in a smooth, seamless finished product. A good product not only looks better, it works better.

We also offer very accurate bending services. Using special machinery designed to bend the metal precisely the way you need it. This is significant not only for how it looks, but also for how it functions in your system. Well-done bending can also help ensure that your sheet metal components match up properly and function as they should in whatever it is you’re constructing.

Welding is one of the most important steps in constructing metal items. Welding is the welding process for joining metal together. We have expert welders and utilize their knowledge to produce a solid, durable end product. We offer various types of welding like: TIG, MIG, Spot welding (dependent on your needs). They each have their benefits and we select them based on the best for your goods.

After the welding of your metal piece, we proceed to the finishing stage. Finishing – This essential process provides the piece with a unique appearance and aesthetics. We can apply different finishes to your piece—from painting in your favorite colors to powder coating, a smooth surface coating, to anodising for an extra touch of protection. These finishes not only give a good appearance for your metal parts but also protect them from the weather and help them live long.

We understand time is essential when working on a project. This is why we provide rapid metal prototyping and production. Prototyping refers to creating a model of your metal product to understand how it will look and function before we produce the final product. That way you can make sure everything is tickety-boo. Once you are happy with the model, we move on to making the real parts very quickly. All is performed precisely and trouble-free, so that you can receive what you want as quickly as possible.

service team composed team pre-sales staff are fluent English, engineers experience processing technology. We sure both technical sales personnel work together sheet metal fabrication services communicate effectively understanding requirements customers. offer clients efficient, custom-designed processing solutions that all-inclusive. We aware individuality every project, team make effort ensure smooth finalization project thus, achieving win-win cooperation.

offer transparent open solutions, always seeking long-term partnerships our clients. We convinced integrity cornerstone of collaboration clients. We provide professional advice fair pricing prior finalizing deals. We remain constant contact our customers throughout manufacturing process make sure are sheet metal fabrication services informed. We provide transparency production process. communicate updates resolve issues promptly. welcome suggestions feedback clients any point. have built long-lasting steady relationships a large amount customers thanks our open transparent communications.

sheet metal fabrication services renowned for ability develop new ideas quickly efficiently. Based extensive communication clients rapid adaptation design changes throughout development phase, offering most knowledgeable advice refine drawings expedite process. We helped clients develop thousands new products utilizing 15 years expertise custom metal processing. clients enjoyed edge in market a result our innovative products have created. commitment quality makes sure that clients get most effective solutions helps navigate competitive landscape confidence.

sheet metal fabrication services order system functions using scientific approach, ensures quick processing tracking each order made customers. Through streamlined ordering platform, customers to submit orders quickly check their status real-time. We insist precise processing orders keep open dialogue clients during entire manufacturing process swiftly addressing design modifications requests upgrades. Whatever size your order approach every order meticulous attention, ensuring prompt processing quality results. dedication excellence underlines dedication exceed customer expectations every interaction.