Have you ever examined metal (faling for example) and how was it made, like in the furniture or your car? You might be surprised to find out that it could have been made through a sheet metal machining process. This fun process is where they take a flat metal strip that has been cut, bent or molded and forms new shape entirely. Sheet metal machining is harnessed by wide range of industries to manufacture a plethora of everyday metal products.

But what is sheet metal machining and how does it work? This uses special machines and tools to cut the metal with a high degree of precision. To create a metal part, a computer program (or sometimes an experienced machine operator) writes instructions that direct how the part is made. This design is then closely traced by a machine to form the metal into the appropriate shape. The way this works is called CNC machining, meaning computer numerically controlled machining. It is used in various sectors where the production of accurate and detailed components matters a lot.

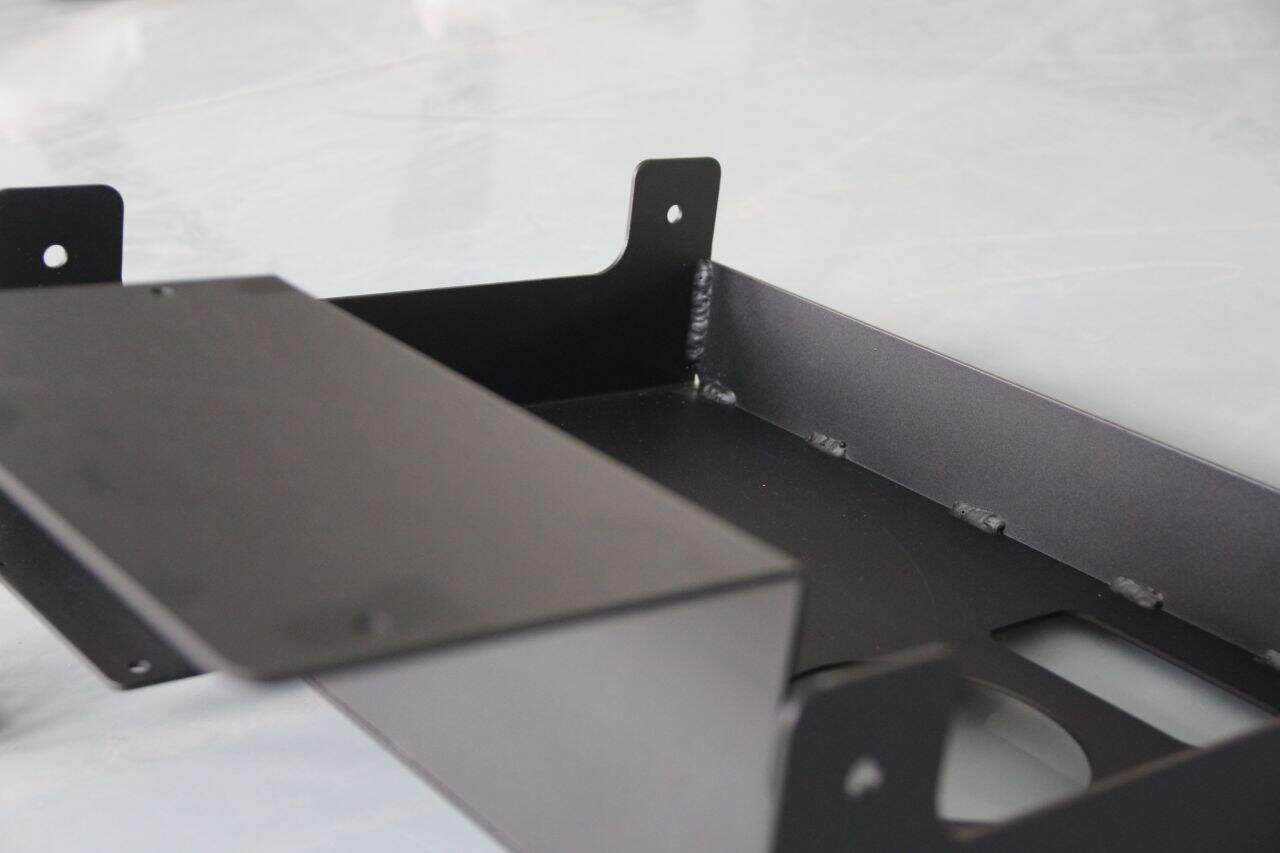

Creating special and unique designs is what sheet metal machining can do that I love. The designers can imagine any shape or thing that they intend to make, and the overall idea is executed utilizing the sheet metal machining process. So we can have a custom design and use if for several purposes. For example, they might be designing machine-specific parts and beautiful home decorations or the unique cars of people dreams in the future. This is a very creative process that gives the opportunity to explore various ideas that can have huge impacts on both appearance and functionality.

Sheet metal machining is one of the most widely used processes in numerous industries due to its many advantages. Perhaps, the greatest advantage it provides is its accuracy. It means that parts are manufactured accurately so that they fit together seamlessly without any play or error. When it comes to machinery, this is so crucial because even the smallest error could cause major issues further down the road.

When we hear the term sheet metal machining, most will probably think that it is complicated; while this is not completely wrong, it nevertheless represents an essential technique in manufacturing and production. Several important steps are performed to sheet metal like cutting, bending and shaping to prepare it into a final product. This machining operation is done with heavy machinery like CNC machines which will cut and form the metal according to the programme designed.

That makes sheet metal machining an extremely efficient and economical way of producing metal products. There also will be a tight accuracy in the process so that every part is well-fitted and does not have an error that can create a problem. Such precision is important for machinery and equipment; this makes sheet metal machining a suitable process for industries looking to manufacture considerable batches of parts quickly and accurately.

Sheet metal machining is simply an amazing technology that has revolutionised the way we manufacture products. CNC is capable of producing exact parts and products using computer-aided CNC machines to meet the specifications that designers come up within the creative process. Not just cost-effective for many businesses, sheet metal machining is a process widely considered to be much better than a lot of other production processes out there in the world.

ability handle new project development characterized efficient adaptable capabilities. quickly adapt changes design product during development machining sheet metal. constant interaction clients allows us offer expert insight improve drawings improve speed development. With 15 years experience custom metal processing, we've guided numerous clients creation thousands new products. clients benefited advantages competition because innovative products designed. commitment excellence makes sure clients get best solutions allow navigate through competitive market confidence.

order system advanced operates scientific efficiency, guaranteeing quick processing tracking every customer order. Through machining sheet metal order management platform, customers effortlessly submit orders check status real-time. place high priority the precision delivery orders. addition, maintain open line communication our customers during entire manufacturing process. lets us respond swiftly requests design changes improvements. Each order handled same level attention, making sure processed promptly delivered high-quality manner. quality-focused approach demonstrates dedication surpassing customer expectations every interaction.

provide open transparent service, are always looking long-term partnership our customers. We strongly believe honesty is foundation of collaboration clients. machining sheet metal negotiating deals offer fair prices professional guidance. We remain constant contact customers during entire production process so are aware. Are transparent about manufacturing process communicating updates fixing any issues as quickly possible. Customers invited give feedback anytime. developed long-lasting, steady relationships large number clients thanks transparent open communication.

service team composed team pre-sales staff are fluent English, engineers experience processing technology. We sure both technical sales personnel work together machining sheet metal communicate effectively understanding requirements customers. offer clients efficient, custom-designed processing solutions that all-inclusive. We aware individuality every project, team make effort ensure smooth finalization project thus, achieving win-win cooperation.