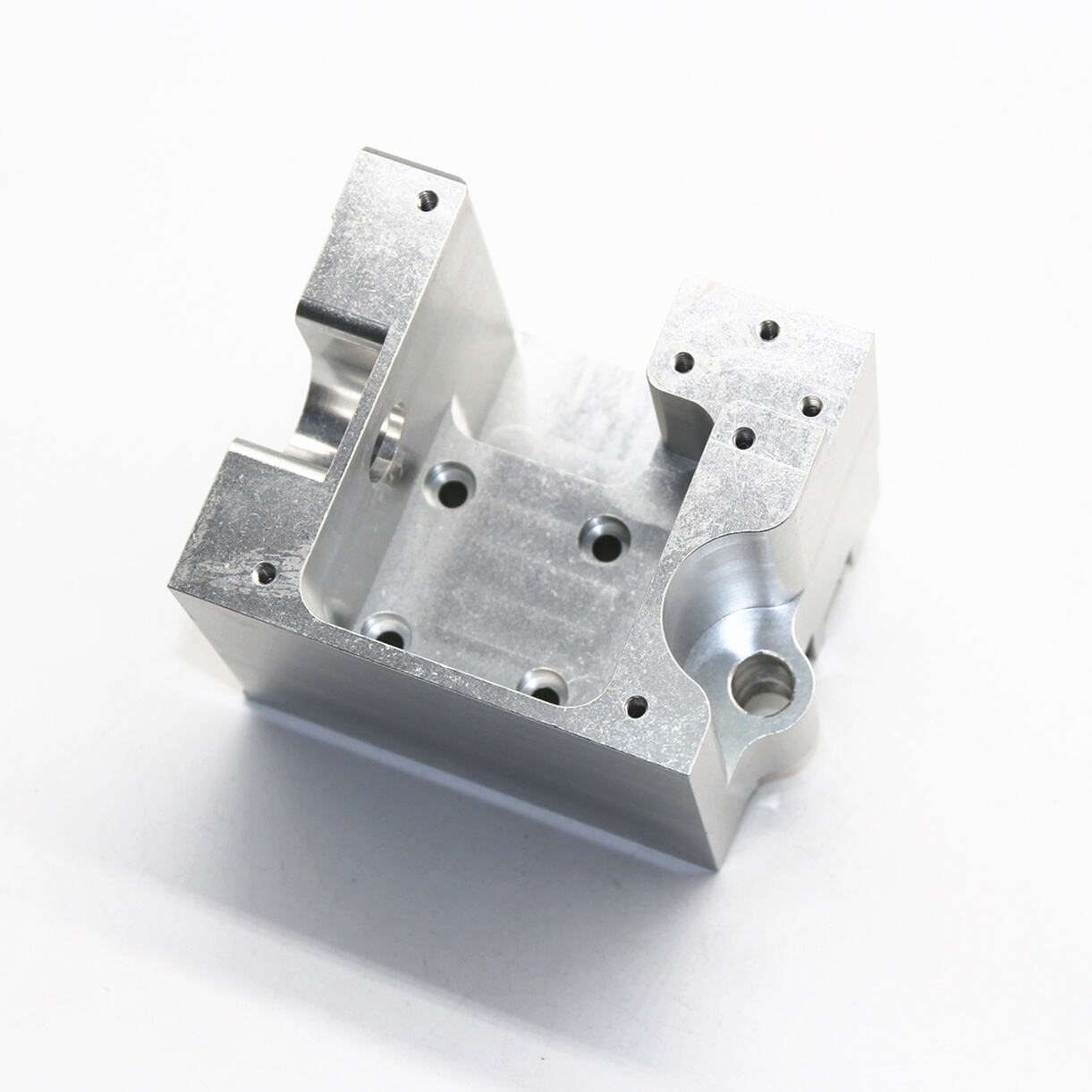

It is really essential to be accurate and careful when we are producing dissimilar products. In the manufacturing sector, this particularly holds true. 4 axis CNC machining helps in this. Introduction to CNC. CNC is short for computer numerical control. This means that the machine is controlled by a computer and it is informed what to do. The "4 axis" portion signifies the machine can pivot the cutting device four distinct methods, up/down, and left/right. This skill enables the machine to accurately cut and fashion metals, plastics, woods, etc. When done properly with cnc machining axis technology, finished goods will be perfectly formed and fitted.

Starway produces wide range of high level products with 4 axis CNC maching. Their custom cnc machining machines are also highly capable, allowing them to perform custom shapes and designs with ease. Which translates that the products it manufactures, are manufactured to be how they should- no errors. Starway has a dedicated staff of highly skilled engineers who are committed to providing engineering with utmost precision. This much greater level of precision is the highest in the industry and differentiates them over other companies.

One of the major advantages that 4 axis CNC machining offers is that it enhances the precision in production. Back in the days, manual work were heavily dependent on workers to do many manufacturing processes. Even if the workers are experienced, manual processes can introduce inconsistencies and errors. But, with cnc parts machining every single product is manufactured in exactly the same fashion. It ensures uniformity which helps to keep a high standard in all the commodities.

Starway machines are so accurate that they manufacture products as exact as (0.001) mm which is too precise. Such precision holds great significance within industries such as aerospace, and the medical device industry. Every little thing count as any small mistake in these fields can cause severe issues, making having such accuracy vital for safety and functioning.

The technology for 4 axis CNC machining has only improved over the years. These machines are now capable of performing what was once unimaginable for humans. For instance some machines can create complex 3d shapes and designs. This can be very beneficial for industries such as automotive and aerospace, where constant updates and innovative designs are crucial.

Within manufacturing industries, consistency becomes extremely vital. With 4 axis CNC machining, each product will be produced to the same exact standards. This guarantees uniformity in quality and design. In industries such as automotive and aerospace, safety is key — meaning this type of consistency is vital.

Having 4 axis CNC machining has many benefits but being a suitable process among numerous industries is one of the most highlighted ones. They can produce a variety of manufactured goods, from basic components to elaborate shapes and designs. This quality makes them perfect for multiple sectors like automotive, aerospace, medical device manufacturing, etc.

offer 4 axis cnc machining transparent service, are always looking long-term relationships our clients. believe honesty is cornerstone of partnership our customers. provide expert guidance fair pricing prior making agreements. keep constant contact our clients throughout process production so they aware. also provide transparency about manufacturing process, giving updates responding any issues promptly. We open feedback suggestions customers any time. Through open transparent approach, have forged steady long-term partnerships increasing numbers customers.

service team composed team 4 axis cnc machining are proficient English well as engineers an expertise processing technology. collaborating between sales technical personnel we able communicate effectively customers, while that are able understand needs. enables provide customers convenient one-stop customized processing solutions. team dedicated ensuring project running smoothly.

We known ability design new projects quickly efficiently. Grounded extensive client communication, we promptly adapt product design alterations throughout development phase, 4 axis cnc machining professional advice improve drawings expedite process. We helped clients thousands products using 15 years experience custom metal processing. These new products garnered stellar market feedback giving clients advantage competition. commitment quality guarantee clients receive highest quality solutions helps navigate competitive landscape confidence.

order system advanced operates scientific efficiency, guaranteeing quick processing tracking every customer order. Through 4 axis cnc machining order management platform, customers effortlessly submit orders check status real-time. place high priority the precision delivery orders. addition, maintain open line communication our customers during entire manufacturing process. lets us respond swiftly requests design changes improvements. Each order handled same level attention, making sure processed promptly delivered high-quality manner. quality-focused approach demonstrates dedication surpassing customer expectations every interaction.