Polymetricum carbonicum est genus unicum plasticum, ideo usum habet ad creanda alia commoda objecta. Communis modus creationis productorum per polycarbonatum est per processum qui injectionem formandi nuncupatur. Processus injectionis formandi incipit cum fusione plasticorum ad statum glutinosum. Proxima gradus est eam fundere, deinde eam coactare in formam, quam figuram cavam que depictat formam producti finalis. Hoc processu potes generare magnum numerum rerum velociter et facile.

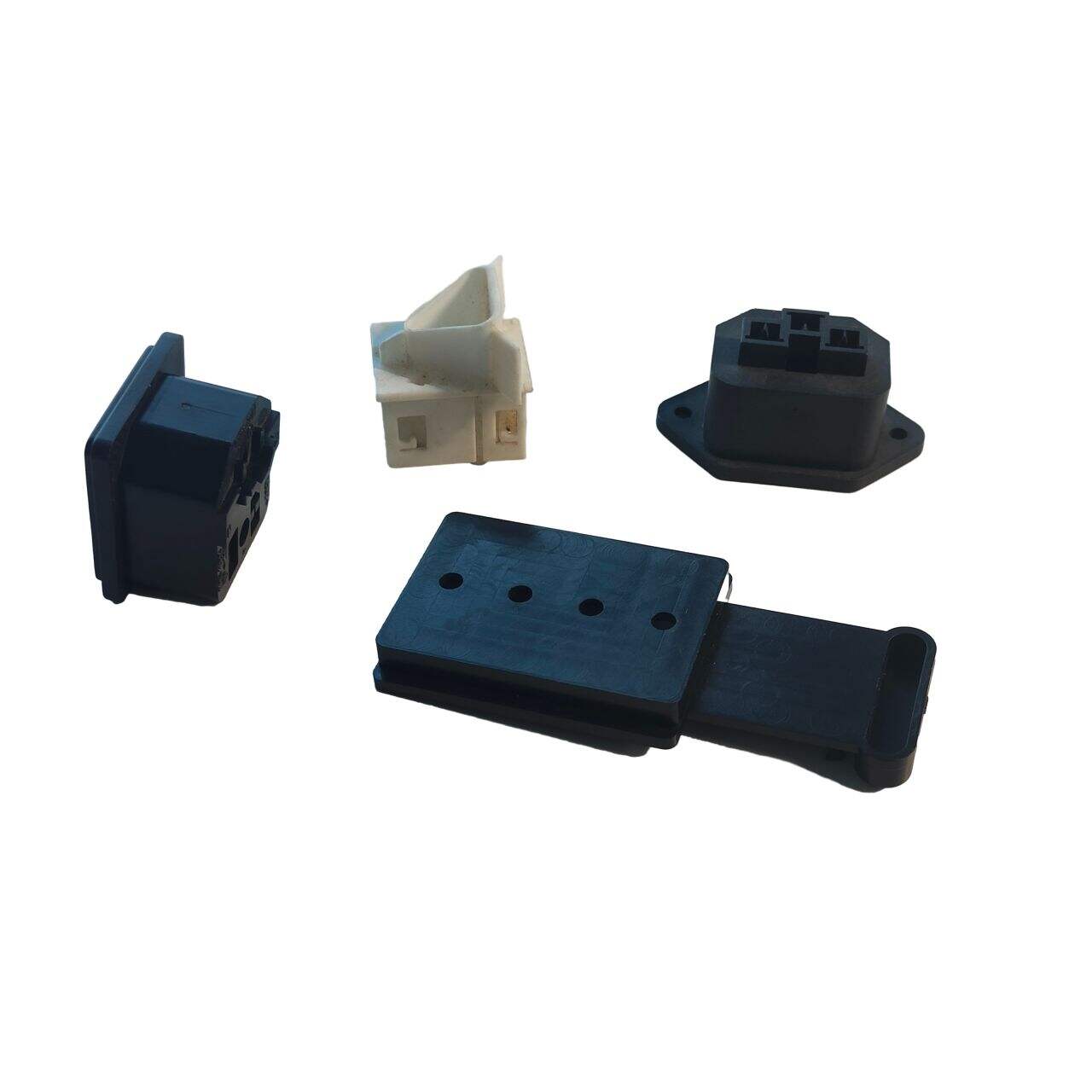

Polycarbonas appellatur materies thermoplasticus, quae iniectione formatur ad componentes solidos polymerizatos polycarbonatis. Polycarbonas est materia robusta et ideo potest sustinere magnum usum et damnum. Optima est ad faciendum res, quas homines integre utentur iterum et iterum absque frangendo. Hoc processus applicatur multis modis — notabilius, habemus custodia telephonorum, quae sunt ut pellices protectivae instrumentorum nostrorum, partes automobilium, quae permitunt performance integratam in viis publicis, et vitra fenestras, per quae secure caelum (aut terram, infeliciter) aspici potes cum in aere es.

Praeterea, formas complexas facile obtinere licet utendo cNC Machining , quod est alterum beneficium huius processus. Quia plasticum in formam injectum fit, potest communicare quamlibet designatio quae necessaria est. Hoc significat quod producta cum complexis et detailed feature possunt creari cum minori labore et maiore expeditione. Praeterea, item fabricata hoc procedendo habent excellentiores finitiones. Illa videbuntur nimis lenia et nitida; id refert ad clientium satisfactionem.

Formatio injectionis polycarbonatis est etiam oeconomica pro productione productorum. Quoniam eius processus est celer, producta cito fiunt, et minus manus operaris necessaria est. Hoc iuvat limitare sumptus pro negotiis. Praeterea, hic modus permitit productionem multorum productorum simul, ducens ad etiam minores sumptus. Hoc est praecipue utile pro firmis quae requirunt velocem productionem magni voluminis bonorum. Maxime pro his negotiationibus parvis in budgetis, servare sumptus, et facere qualia producta est situatio victrix.

Sicut etiam injectio polycarbonatis amica est naturae. Hoc partim fit quia producta polycarbonatis robora et dura sunt. Si res diutius permaneant, non tam frequenter eas immutare debemus, quod in pauciores usus materiae resultat. Polycarbonatus etiam recyclabilis est, quod magnum praebet commodum. Polycarbonatus recycletur per fusum et novi producti polycarbonati ex eo conficiuntur. Hoc processus adhibetur ad impedientem dejectos in sepulcra transferri et adiuvat ad tuendum terram nostram.

Legere genus aptum polycarbonatis resinam et eventuales additiva est gradus importans in injectione polycarbonatis. Resinae sunt materiae bases quae plasticum continent; additiva sunt composita specialia quae meliora faciunt proprietates plastici. Haec additiva possunt fortificare plasticum, eum flectibiliorem reddere aut melius calorem sustinere. Cum mixtura recta et aequilibrio resinarum et additivarum, fabricatores possunt meliorem qualitatem productorum suorum finitorum perficere.

Starway praebet formandum per iniectionem polycarbonatis. Scis quod polycarbonatum est optima optio, cum plura aspecta eius ut materiae consideras. Possumus tibi adiuvare in eligendo convenientissimam mixtionem resinarum et additivarum quae optimē conveniunt specificis requisitionibus productorum tuorum. Nostri periti tibi adiuvent creare producta qualia, fortes, durabilia, et oeconomica quae satisfaciunt requisitionibus tuis.

servitium professionalium equiparum comprehendit praevenditionis officiales qui loquaces sunt in commerciis Anglicis, ingeniores periti in tractando technologia productus. coniungentes venditionem et technicos ministros, certificatur communicationem efficientem cum nostris clientibus, dum intelligunt requisita. offerunt clientibus formandum injectione polycarbonatis, consuetudo-designata processuum solutiones uno stop. intellegunt specificitatem cuiusque projecti, ideoque equipa non parcit effortui ad certificandum expeditam finalitatem projecti tui attingendo cooperationem utriusque parti beneficiam.

systema efficientis administrationis formarum injectionis polycarbonatis, scienter designatum, velocem finitionem cuiusque ordinis a clientibus locati garantit. Systema administrationis ordinum concedit clientibus facile submittere ordines et secutari statum in tempore reali. Prioritatem ponere in accurate processing ordinum et tenere regularia communicationes cum clientibus per totum processum fabricationis, prompte respondendo ad modificationes et petitiones de designio et progressibus. Sine respectu magnitudinis ordinis, ad quamque ordinem cum sollicitudine accurata accedimus, secure effectivos processus ordinum cum optimis resultatis. Devotio excellentiae patet in dedicatione ad satisfaciendum et superando expectationes clientium in omni gradu itineris.

Nos celebrata capacitas novos projectos celeriter et efficienter creamus. Cum magna in communicationem clientium accentuatio, prompte adaptamus alterationes in designum producti per totum progressum developmentis, praebentes peritiam ad clarificandas delineationes et accelerandas processum. Uti 15 annos expertitia in designum custom metal processing, iuvavimus multos clientes creando milia productorum unicum. Clientes profuerunt ex praeparationibus adversus competitionem propter novos productos quos creaverunt. Nostri ad committendum qualitatem citius facit ut clientis optima solutiona accipiant et iuvet in polycarbonate injection molding in confidantia competitive landscape.

offero servitium formandi per iniectionem polycarbonatis transparentis, semper quaerentes relationes longevas cum nostris clientibus. Credo quod integritas sit fundamentum societatis cum nostris clientibus. Praebemus directionem peritam et praeciosum iustum antequam conficiamus pacta. Tenemus contactum constantem cum nostris clientibus per totum processum productionis ut sint conscii. Praeterea, praebemus patefaciem de processu fabricationis, dantes renuntiationes et respondentes cito ad omnes difficultates. Aperti sumus ad feedback et suggestiones a clientibus omnibus horis. Per approach apertum et patefaciem, fecimus relationes firmas longevas cum crescente numero clientium.