Componentes formarum sunt una ex partibus maximis importantibus in forma injectionis. Hae sunt singulae partes quae formam simul componunt. Injectio formae est processus quem adhibemus ad creandum res plasticas. Initium omnium sumit a plasta liquefaciendo. Starway iniectio CUMATIUM plastam liquefacit et in formam iniecit. Tum cum plastica refrigerat, formam eius quod in forma est accipit. Hoc modo, possumus conficere multas res plasticas quas cotidie occurrimus.

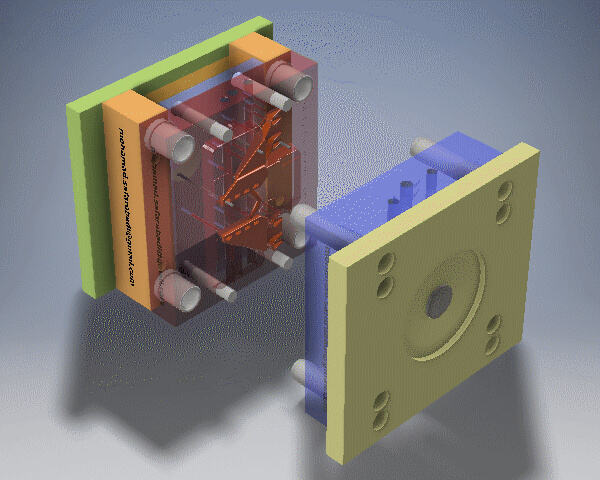

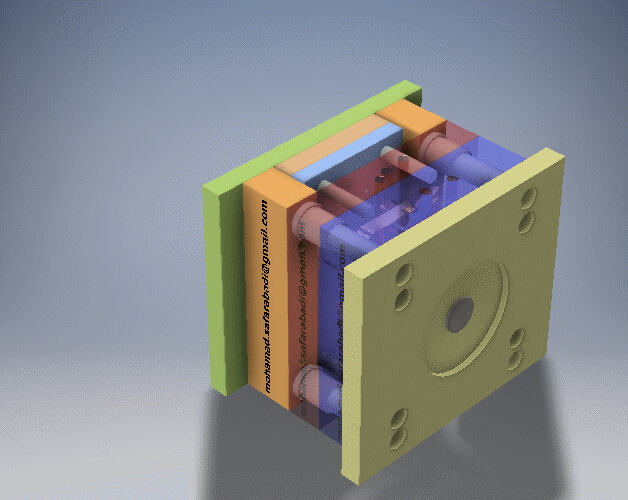

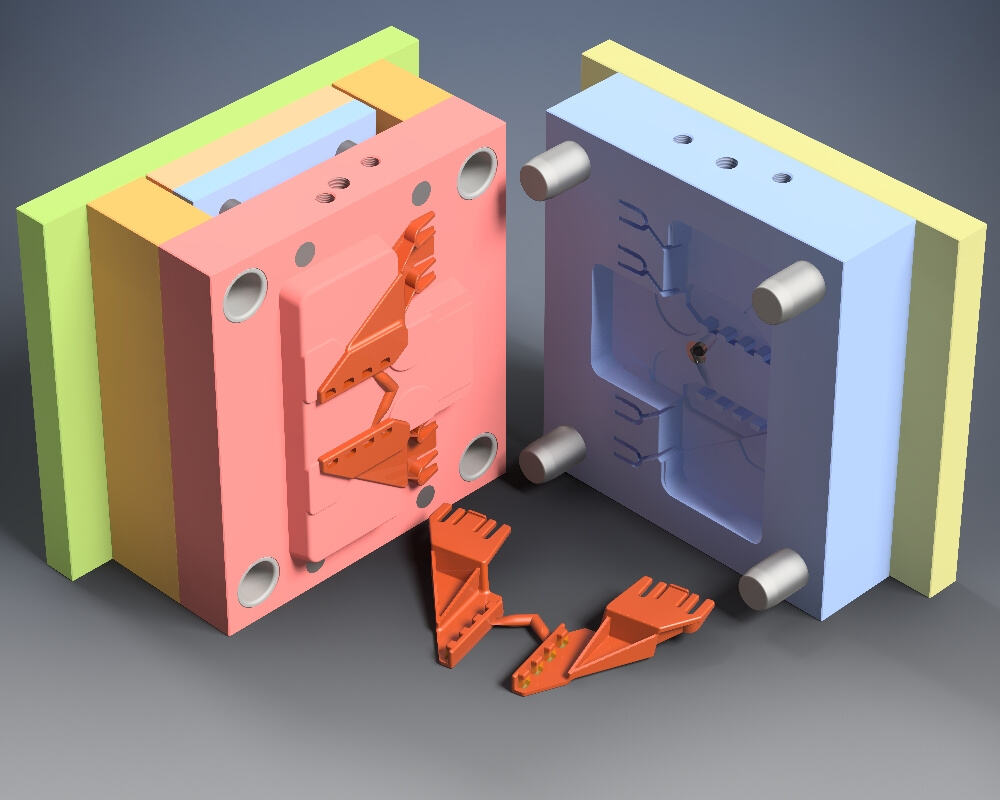

Partes formarum sunt significativae in conficiendo omnibus generibus formarum plasticarum. Componentia principalis formae constat ex duabus partibus. Prima pars, quae cavitas dimidium appellatur, et secunda pars, quae nucleum dimidium dicitur. Cum istae duas partes coniunguntur, faciunt geometriam particularem objecti plastici desiderati. Uti variis partibus formae omnes simul operantes ut hoc eveniat, permitte fluere productum finalem accurate.

Starway est faber componentium formarum altius qualitatis. Hae partes qualitatis sunt valde necessariae, quoniam iuvant in celeri & optima operatione processus formandi injectionis. Hae Starway forma injectionis plasticae custom possunt celerius haec producta plastica conficere utendo bonis partibus formae, quod omnibus prodest. Insinuat etiam hoc posse nos optima qualitas producta plastica sine longo expectando consequi. Praeterea, si utimur partibus formarum altissimae qualitatis, formas longam vitam habent et etiam chimica semper perfecte veniunt, quod est elementum clavus in satisfactione clientium.

In conficienda plastica, oportet te plus attendere ad qualitatem et praecisionem. Male factae formae aut specificatio errata possunt causare ut productum plasticum non ita evadat ut volumus. Starway injectio formandi processus est unde partes formae proveniunt, quia securus faciunt ut formae sint absolute perfectae, semper et singulis vicibus. Omnes partes bene convenire debent exacte ut formae recte opus gerant — et, in summa, quam efficacissime fieri possint.

Starway habet multas partes formarum quibus clientelae eligere possunt. Unusquaque componentis unam functionem in creatione rei plasticae habet. Electionem componentium pro omni projecto facere valde necessarium est ad efficiendum systema totum functionalis. Starway etiam specializatur in componentibus formarum ad mensuram. Si cliens partem quandam requirit quam nunc non offert, potest Starwaym contrectare qui libenter hanc fabricabit solummodo pro cliente singulari.

systema administrans ordines summe efficiente, utensiliolum scienter designatum confirmat promptam elaborationem cuiusque ordinis clientium. Gratias platformae simplici ad administrationem ordinum, clientes possunt ordinare cito et monitorare statum in tempore reali. Insistimus executione exacta ordinum et conservamus communicationem constantem cum clientibus durante toto processu fabricationis ad celerrime tractandum petitiones de modificationibus et progressibus. Quicumque sit magnitudo ordinis tui, adquiritur unusquisque cum cura, confirmans elaborationem opportunam et distributionem cum optimis resultatis qualitatis. Devotio qualitati monstrat commissationem ad componentia formandi injectionis et expectationes clientium inter actiones.

communitas servitii constat ex communitate componentium formandi injectionis qui periti sunt Anglica lingua et item ingeniorum cum expertitia technologiae elaborationis. Cooperando inter venditionem et personale technicum, nos possumus communicare efficaciter cum clientibus, dum simul possunt intellegere necessitates earum. Hoc facit ut possimus praebere clientibus commodam solutionem unica-statione et customizatam elaborationis. Communitas dedicatur ad confirmandum ut projectum currat leniter.

praebere solutiones apertas et transparentes, semper quaerentes cooperationem business in longo tempore cum customer. Fortiter credimus quod honestas sit fundamentum relationum cum clientibus. Praebemus consilium peritum et praebemus justam praesionem antequam faciamus pacta. Sumus in communicatione continua cum nostris clientibus per totum processum fabricationis ut certi simus quod informati sint. Praeterea, sumus aperti in processu fabricationis. Communicamus renovationes et addressemus cito problemata. Benevenimus suggestiones et feedback a nostris customer quovis tempore. Habe mus developptas relationes longae durationis et constantes cum magno numero customer Injection mold components propter communicationem nostram apertam et open.

Componentes formae injectionis celebrati propter capacitatem generandi novas ideias cito et efficienter. Fundatum super copiosam communicationem cum clientibus et velox adaptatio ad mutationes in designio per totam phase developmentalis, offertur consilium sapientissimum ad refinandum delineamenta et accelerandum processum. Auximus clientes in evolvendo milia nova producta utendo experientia quindecim annorum in processing metalli custom. Clientes gauduerunt praemium in mercato propter nostram creationem productorum innovatorum. Devotio qualitati certificat clientes accipiant solutiones effectivissimas et iuvet eos navigare per landscapem competitivum cum fiducia.