Quomodo res fiant anni 2025 integre renovatur, merito machinationis laminarum metallicarum. Hoc includit secandum, formandum et effingendum laminas metallicas in partes ad infinita producta. Apud Starway, magnae mutationes in instrumentis et methodis iuvaverunt celeritatem augere et qualitatem partium e metallo fiendarum auferre. Machinae hodiernae sapientiores sunt et multa negotia sine intermissione perficere possunt. Id minus consumptivum est et figuras praecisiores efficit. Qui magnas quantitates partium metallicarum emunt, quaerunt optimam qualitatem pretiumque. Ob hanc causam, 2025 machinatio metallorum laminarum magno cum favore accipitur. Id pecuniam conservat societatibus et certum facit se accipere quae indigeant, quando indigeant.

Si multas laminas metallicas cito et bene effingere debes, tunc opus est tibi peritissima societate Marilyn Burns. Anno 2025, pleraeque respublicae quaerunt machinationes laminarum metallicarum quae magnos ordines sine erroribus aut dilationibus tractare possint. Si quaeris opera fida, non potes errare cum Starway. Starway habet operarios peritos et machinas novas ad secandum, flectendum et formandum laminas metallicas ut opus est. Possunt ingentes suscipere muneris atque tamen qualitatem servare. Id significat ut si plures partes ordineris , unaquaeque eadem ratione conficietur.

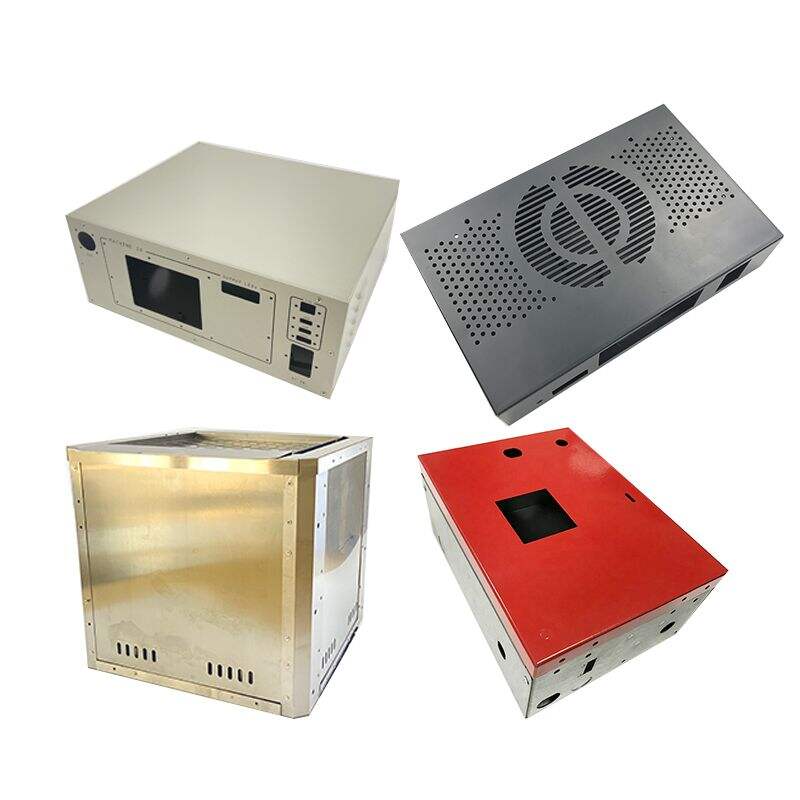

Si quaeris opus in quo possis confidere, quaere societates sicut Starway quae novam technologiam utuntur et bonam habent famam. Vide an ordines singulares et varietates metallorum et crassitudinum suscipere possint. Bona societas etiam tibi adiuvabit optimam materiem et formam ad utrumque eligendam, quae sit economica sumptus PECULIUM et ad tuum productum meliorem faciendum.

Et ferrum in illud collidetur, vibrationes transmittentur. Aliquae novae et interessantes directiones emergunt anno 2025, quae etiam faciliorem et celeriorem productionem partium metallicarum ad fabricas et machinas reddent.

Post quinque annos, multis fabricis opus erit partibus celeriter factis, quae tamen postea mutari possint. Haec res dicitur fabricatio flexibilis. Starway curam suscipit huius rei habens machinas quae inter opera celeriter mutantur. Id est, si mutatio designi a cliente desideretur, Starway id facere potest nihil ceterum tardans. A novum Conceptum 3D impressionem et machinationem metalli laminati complectitur. Hoc Starway permittit partes valde exactas producere quae difficultate fiunt machinis solis.

systema gestionis ordinum valde efficax, instrumentum scientifice concinnatum curat celerem tractationem cuiusque ordinis a customeribus. Gratiā simplicis platformae pro gestionis ordinum, clientibus licet ordines celeriter mittere et statum in tempore reali monitorare. postulamus executionem precise ordinum et communicationem constantem cum customeribus per totum processum fabricationis, celeriterque respondeamus petitionibus de modificationibus designandi vel emendationibus. Quacumque magnitudine ordini tuo, singulos tractamus cum cura, ut processing et deliveratio fiant tempestiva et resultata sint summae qualitatis. dedicatio nostra qualitati demonstrat commitment ad expectationes customerium anni 2025 in machinatione metalli laminati in omnibus interactionibus.

team operarum compositum ex team anni 2025 in machinatione metalli laminati sunt proficisci in lingua Anglica, necnon ingenieros habentes expertitatem in technologia processus. Colloquentes inter personalem sale et technicum, efficaciter communicare possumus cum customeribus, simul intelligentes eorum necessitates. Hoc permittit ut customeribus solutiones processuales personalizatas unico-loco commodas praebere possimus. Team deditum est ut projectum recte et sine interruptionibus progrediatur.

praebemus apertum transparentemque servitium, semper quaerimus diuturnam societatem cum nostris clientibus. Firmissime credimus quod integritas sit fundamentum collaborationis cum clientibus. In 2025 tractationibus de machinatione laminarum metallicarum, offerimus pretia aequa et directionem professionalem. Manemus in constanti communicatione cum clientibus per totum processum productionis, ut sciatis. Sumus transparentes de processo fabricationis, nuntiando novitates et corrigentes omnes difficultates quam celeriter possibile est. Invitamus clientes ut commentarios demant quando libuerit. Fecimus longinsecas, constantesque relationes cum magno numero clientium gratias actas communicationi apertae et transparenti.

Scimus nos posse celeriter et efficaciter nova proiecta designare. Fundati in ampla communicatione cum clientibus, celeriter adaptamus mutationes in designo productorum per totam phasim developmentus; anno 2025, consilium professionale de machinatione laminarum metallicarum meliorat disegnationes et processum accelerat. Auximus clientes in millia productorum per 15 annos experientiae in tractatione metallica ad mensuram. Haec nova producta laudem egregiam in foro consecuta sunt, ita ut clientibus praerogativam prae concurrentibus tribuant. Commitmentum nostrum ad qualitatem pollicetur ut clientes solutiones maximae qualitatis accipiant, quod eos iuvat ambitum competitivum confidenter navigare.