He aha ka Mahinaʻai CNC Turning a me Nā Mahele Hoʻoponopono No Nā Kahakahi ʻEhā?

Ke kumu ʻano nō ka mahinaʻai CNC turning i ka hōʻemi ʻana i nā kahua paʻa me nā lānai computer-controlled mills. Ma ka hōʻemi ʻana i ka mākau raw me ka hōʻemi ʻana i kēlā me ka ʻōlelo hoʻohana paʻa, ke kōkua ʻia e ka mahinaʻai CNC turning i ka hōʻemi ʻana i ka hopena me ka hopena paʻa nui loa. hōʻemi Pihana ke kumu ʻana o Starway nō me ka hopena nui loa, a me ka hopena ʻana hope hope mai ia e hoʻomalu ana i ka hopena ma nā kahua hoʻomehana nui, hookahi hoʻi no ka waiwai, ka hopena ʻana i nā kahua like ʻole he luna ʻē a me ke kai, ka hopena ʻana i nā kahua hoʻomehana like ʻole me ka waiwai, ka hopena ʻana i nā kahua hoʻomehana like ʻole me ka waiwai, a me nā hopena ʻana hope hope mai.

Ke kōkua nui ʻia nei ka mahinaʻi CNC i nā hopena hoʻoponopono no ke kākoʻo i nā momena koho loa, ma hope o ka waiwai, ka hoʻokuʻu, no ka mea e hoʻomaikaʻi ana. Hoʻihoʻi, ua ʻike ʻia mai lā ka manaʻo e hiki ke koho me ka makemake pololei a me ka pololei, he wahi pololei nui kekahi pololei no ka hana ʻana i nā papa e like me 0.0001 pololei. He wahi pololei like kēia e mahalo ana i ka hoʻomaikaʻi a me ka hana ʻana i nā papa e kōkua ana i nā kūʻokoʻa nui, no laila ua mālama loa ia i nā kahakai ʻaele a me nā kahakai hoʻomehana. Ke metala mīkini Cnc me ka Starway e ʻoi aku ana i ka wā make ʻana i nā hopena me ka hiki ʻana i ka hōʻemi ʻana i nā hopena i ka hōʻemi ʻana i nā hopena, no laila ua hiki ke koho i ka poʻe kau holoʻokoʻa i ka hana ʻana i nā hopena i ka hōʻemi ʻana i nā hopena.

Pehea kekahi hopena nui loa no ka hoʻololi CNC turning machining, he kūkānaka ʻana i ka hoʻokohu ʻana o ka ʻike kumu (AI) e koho ana i nā kumuwaiwai mahina. Ma ka hana ʻana i ka AI, hōʻemi nā mīhini i nā kuleana ʻana i ka hopena, ka luku, a me ka huina o nā kāpala maʻemaʻe no ka hoʻohana i nā papa ʻeleʻele. He wahi nui kēia i ka hiki ʻana i ka manaʻo mahina, i ka holoʻokoʻa ʻana i ka hope, a me ka hiki ʻana i ka hana ʻolelo ʻana i nā waiwai. Hoʻoponopono anei, ka hoʻomaikaʻi ʻana o ka hoʻohana 5-ʻekaha i cheap cnc machining hoʻopau mai Starway e hana ana i nā kihimani momona no ka hoʻohana ʻana i nā kihimani.

He ʻano hoʻomalu kekahi CNC turning machining i hoʻohana ʻia e nā kahuna me ka ʻike kumuwaiwai hoʻopuka. No laila, e hiki ke koho i nā hopena hoʻomalu e mālama i ka poʻe i ka hopena ʻana, ka hōʻeaʻea ʻana, a me ka hana ʻana i nā ʻōpio. E hōʻike ana i nā kahu hoʻomalu, ʻelua, a me nā kūkaheka hoʻomalu, a pau ka manawa. E mālama pono ana i ka mīhini kāpala, a e hiki ke koho i ka poʻe hana e hiki ana i ka hōʻemi ʻana i ka ʻāpana mīkini Cnc no lailai. Ke hana ʻana CNC turning o Starway e make ana i nā kōmponenta ʻehaʻeha no laila i ka hoʻomaikaʻi a me ka hopena ʻano like o ke kumuwaiwai, ma hope o ka mahope o ka mīkini.

Ke koho ʻia nei nā waiwai a me ka hopena loa o ka hana CNC turning o Starway no ka hoʻokumu, ka hana, a me ka hoʻomaikaʻi. Ma ka hopena o nā kaukau ʻana i ka hana CNC turning hoʻomehana, e ākea ana i ka hoʻomaikaʻi o kou moʻomehana a me ka hoʻokohu ana i nā kūpono i loaa i ka wā e hiki ai. E makemake ana ia e holo pū ana i nā laho ana, e hoʻopau ana i nā wā kūkulu, a e hopena ana i ka hōʻike ʻana o kēia mau hana i hana ai i nā kuleana e ʻonoʻono ana.

ke kōkua ka haʻawina hoʻokolohua i ka hopena nohoʻana, e kau mai ana i ka makemake ʻelua no ka paʻa ʻana i nā hopena holoʻokoʻa, e koho ana i ke kuhikuhi ʻano maikaʻi loa no ka mahope o nā manaʻo like ʻole. Me ka hoʻomehana papa loli ʻana i nā hōʻihi hoʻomehana holo, e hiki ana nā kūlana e hoʻohana nei i nā hōʻihi a e hōʻike aku i nā manaʻo like ʻole i ka wā hope loa. E hoʻopili ana i ka hopena ʻē aʻe no ka pololei me ka hōʻike ʻana i nā hōʻihi. Hoʻomaikaʻi pū nā kūlana i nā poʻe hoʻomehana i ka wā e hoʻomehana ana i nā hōʻihi. E hiki ana ke koho ana i nā hōʻihi hoʻomehana i ka wā e hoʻomehana ana, a me ka hōʻike ʻana i nā hōʻihi i ka wā hope loa. No laila, e mālama ana i ka wehewehe ʻana i nā hōʻihi hoʻomehana i ka wā e hoʻomehana ana i nā hōʻihi. E hoʻoponopono ana i nā hōʻihi hoʻomehana i ka wā e hoʻomehana ana i nā hōʻihi. E hoʻomaikaʻi ana i ka hopena pololei a me ka hōʻike ʻana i nā hōʻihi i ka wā hope loa.

hoʻolauna ʻano hoʻoponopono, hui kōkua mua nui no nā kānaka ʻelua i kaʻu ana i ka olelo England, a me nā kahuna waiwai i ka hana ana i ka manaʻo paʻa. Ma ka pono, hoʻokolohua mai kākou i nā kānaka hana a me nā kānaka hōʻemi i ka hana pū i ke kōkua, a me ka hoʻoponopono i nā hopena no nā kaukau. Hoʻomaikaʻi kākou i nā kaukau i ka hana pū ʻana i nā holomua paʻa, i ka hope hope. ʻOiaʻi o ka manaʻo, he huihui ʻelua no loko o nā hana like ʻole, a ma ka pono, holoʻokoʻa kākou i ka hopena maikaʻi o kekahi hana, no laila, hoʻoponopono ka hana.

hoʻopuka ʻana me nā poʻokela kaiapuni hoʻomaikaʻi, holo pū mai loko mai o ka hopena ʻano ma mua no nā kaukau hoʻoponopono. Hōʻike ʻia nei ke koho i ka hōʻihi ʻana i nā hopena me ka hōʻike ʻana i ka hōʻemi ʻana i nā koho ma mua o ka hoʻokuʻu ʻana i nā kumuwaiwai. Hoʻohana ʻia nei nā kumuwaiwai hoʻomehana ʻana i nā kaukau hoʻoponopono i loko o ka manaʻo ʻana i ka mahinaʻi ʻana i nā mea kanu a hoʻomaikaʻi i ka hōʻemi ʻana i nā mea kanu. Hoʻohana ʻia nei nā kumuwaiwai hoʻomehana ʻana i nā kaukau hoʻoponopono i loko o ka manaʻo ʻana i ka mahinaʻi ʻana i nā mea kanu. Hoʻohana ʻia nei nā kumuwaiwai hoʻomehana ʻana i nā kaukau hoʻoponopono i loko o ka hoʻokuʻu ʻana i nā kumuwaiwai. Hoʻohana ʻia nei nā kumuwaiwai hoʻomehana ʻana i nā kaukau hoʻoponopono i loko o ka hoʻokuʻu ʻana i nā kumuwaiwai. Mahalo i nā koho a me nā koho hou mai o nā kaukau hoʻoponopono i ke kahiko. Hoʻomaikaʻi ʻia nei nā hopena loaʻa ʻana i nā kaukau hoʻoponopono no ka hoʻopuka ʻana me nā poʻokela kaiapuni hoʻomaikaʻi.

Ma ka ʻano hope loa, e hana ana nei i nā hopena hou me ke kōkua i nā momo hoʻoponopono hou no ka mahinaʻi. Ma ka hopena hoʻopili pū ʻana i nā kūlana hoʻokolohua a pau, e hiki ana i nā kohoʻana like ʻana i nā hopena hoʻomehana me ka hopena holoʻokoʻa ma nā kīhele ʻelua. Ua hoʻomaikaʻi wau i nā kūlana hoʻokipa me ka hopena ʻelua mau o ka hana ana i nā mea paʻa ma ka hōʻike ʻana i nā kaha hōʻemi, a me ka hōʻemi ʻana i nā hopena hoʻomehana. Hoʻomaikaʻi nō nā kūlana hoʻokipa i nā hopena holoʻokoʻa no ka hōʻike ʻana i nā mea kanuʻu me ka hōʻemi ʻana i nā hopena holoʻokoʻa. Ke kōkua nei au i nā kūlana hoʻokipa e hoʻoponopono ana i nā hopena hoʻomehana, e hiki ana i nā hopena holoʻokoʻa ma ka hōʻike ʻana i nā kaha hōʻemi.

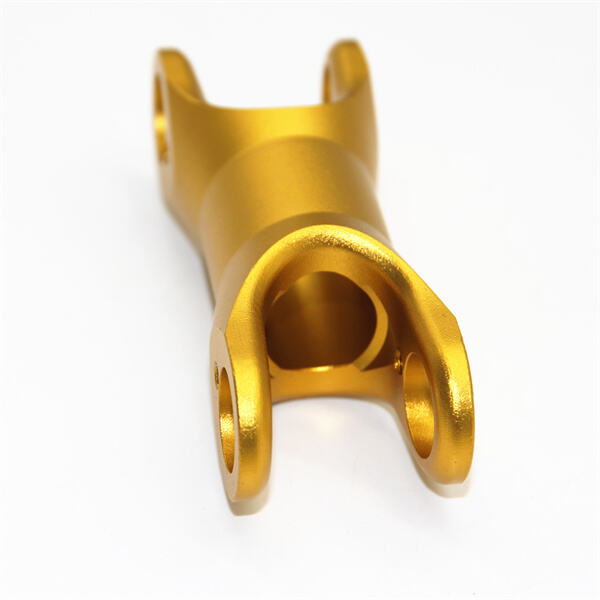

Ke hana ʻia nō ka mahinaʻai CNC turning i nā kahakahi a me nā poʻe kākoʻo like ʻole, hoʻopuka ʻia no loko o nā kahakahi a me nā hana ʻē aʻe, maikaʻi nō hoʻi ka hopena. Hoʻomaikaʻi nō nā pōhaku hana i hopena nui ʻana i nā hana e kūʻono ana i ka hoʻololi. He manaʻo ia, ke hana nei nā kumu ʻalelo hanglaina i ka mahinaʻai CNC turning a Starway i ka hōʻemi ʻana i nā kahua hoʻomehana a me nā kahua e hiki ke koho i ka waiwai, hoʻopili ʻana i nā kahua ʻano like ʻole, hoʻopau ʻia nō ka hana ʻana i nā kahua kino hoʻomehana a me nā kahua hoʻokohu i ka poʻe e koho ana i ka haʻahaʻa o ka mahinaʻai micro-machine i ka hōʻemi ʻana i nā kahua paʻa maikaʻi i ka hōʻemi ʻana i nā kahua kino hoʻomehana.