I kēia wā, ʻo ka kaukau laser kekahi kinetikala e hana ai i ka umi, ʻaʻole ʻo nā kapuhi, ʻaʻole ʻo nā nife! Maikaʻi loa, ʻoiai? Aia, he maikaʻi kēia! No laila, he laʻana, ke komoani e hana umi a me nā kaukau laser nui no nā hoʻoloho maikaʻi no nā mea kūʻai. Ua hoʻonohonoho ʻia no ka hoʻolālā ʻana i nā ʻaoʻao o nā māhinahina a i ʻole nā hana kreatio. I kēia heluhelu, e kūkulu mākou hoʻoluʻu kīpapa mea kanuʻu a me ka hopena o ia i ka hana ʻana i nā mea kanu ʻē aʻe.

ʻO ka waiwai nui ʻole o nā mea maikaʻi mahope o ke kūkulu iʻa e hōʻike ana i kona manaʻo loa. Ma hope o loko, he hopena polohua kaʻu. Ke kūkulu ʻia e kēlā i nā wawae like ʻana i ke kahua hoʻomehana nohoʻana i ka mīkini! E hiki ana ia i ka Starway hopena i nā kauoha kumuhana i ʻole e hopena ana nā kahakai hana ʻē aʻe. Hoʻomalu nei, inā he waiwai nui ke koho i ka hōʻailona piha e hoʻokuʻu ana i ka hōʻailona piha: he waiwai nui ke hiki ke kalohe ana, ʻaʻole hiki? Me ka hopena iʻa, ʻelua ka hopena, ka hōʻike ʻana i ka hōʻailona hoʻomehana.

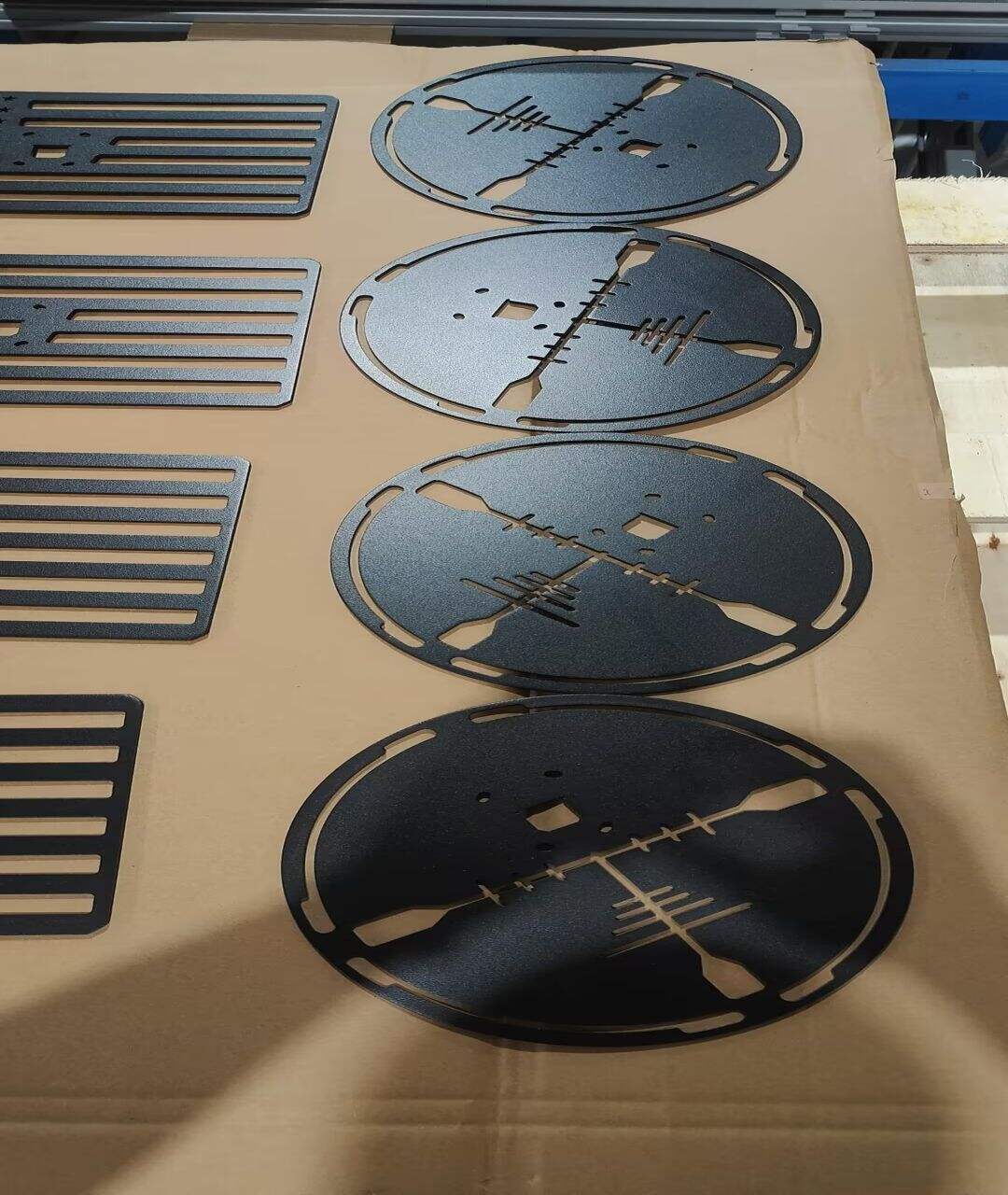

No laila, mahalo nui keia no ka mea e like me ka pōhai, he mea nui loa ia i ka hopena o ka poʻe e hana ana i nā poʻe mano. Hoʻomaikaʻi ka hana ana i nā kūlana e hana ana i mokumoku ʻekahi moana. Maikai loa kekahi mau hopena a pau o ka hoʻomehana lazeri, he waiwai nui loa ka hopena, e koho nei i nā mea kanu ʻole. He mea maikaʻi keia no ka honua, no laila, he waiwai ʻole ka waiwai. He mea maikaʻi pū, no laila, e hiki ana i ka manaʻo e holomua ana i nā manawa, a me ka poʻe kauhale o Starway e like me ka hopena!

Kahi o nā mea maikaʻi loa o ka hakohako lazer he mea he nui nā hewa e hana ai i nā mea e like ʻole me nā mea hana ʻole. Ke kauoha i ka palapala i nā pōhaku a me nā wiliwili, hāʻawi kēia i kā lākou hoʻolālā i kēahi kūmau a i kēahi makemake. Hiki iā lākou ke hakohako i nā ʻaoʻao palapala a paʻa i lākou e hana ai i nā kiʻekiʻe 3D. Hāʻawi kēia iā lākou ke kaha i nā haehae a me nā mea kapa! He laʻana, ame Jacek e hoʻomaka ana me kahi haehae palapala o kahi manu, ʻolohe, a i ʻole kahi lāʻau e like me ke ola!

Mahalo i ka hakohako lazer, hiki ke hana piha nā hoʻolālā i loko o ka palapala. Hāʻawi kēia i nā ʻaoʻao palapala i nā wehewehe a me nā mālama. Eikekomo kahi hāpana palapala e hōʻike ana i kahi hoʻolālā maikaʻi, a i ʻole kahi inoa, a i ʻole kahi palapala, i loko o kāna kikoʻī. ʻO kēia ka mea hoʻolālā pepa kila ʻoki laser e hāʻawi ana i ka mea i kēahi kūmau, a hiki ke kōkua i nā kanaka e ʻike ʻana i kahi palapala. Kēlā me kēia mea hana ʻia e lākou, ma ka hakohako lazer, e hāʻawi ana maikaʻi i ka noʻonoʻo e hāpai ai.

Hoʻomohala ʻAno Helu Mea Kanu Kākahiaka Hoʻomehana i ka hoʻomohala ano mea kanu helu kākahiaka, ke hana nei i nā kahakai ʻelua no laila, ma ka hōʻemi a me ka hōʻemi. No laila, he wahi kūʻokoʻa ka hoʻomehana kākahiaka, no ka mea he poʻe holo kaua nui a me ka pololei o ka hana. Ma nā hale holo kaua, he hopena ka hoʻomehana kākahiaka i ka hana ʻana i nā ʻano kūpono loa no nā wahi hana i hoʻomaikaʻi ai i ka mīkini a me nā kaha hikiʻana. He hopena nui no laila, he hopena nui no ka holo kaua, a me ka hoʻomehana kākahiaka e koho ana i nā komponenti ʻoluʻolu a me ka wēlau wela no nā holo kaua a me nā pūkau hikiʻana. He hopena nui no laila, no ka mea ke kūpono holo kaua e holo wale ana!

Me ka pilina maikaʻi loa, hiki i Starway ke kaukau ʻana i nā laser a me nā hoʻoloha maikaʻi. He laʻana, e hoouka nei nā laser hou e haʻahaʻa a me ka maikaʻi loa ma mua o nā laser e like me kēia manawa. Oiai hoʻoluʻu kīpapa mea kanuʻu e hōhai ai i nā hoʻoloho liʻiliʻi a me ka pono loa. Pehea ʻoe, pehea ʻoe inā hiki iā ʻoe ke hana i nā kiʻi liʻiliʻi a me ka pono piha? Mea hou kahi mea e makaukau ana nei ke kaukau laser me nā robot. E hāwea ai i nā hana maikaʻi a maʻalahi a maʻalahi holo ka hana hana.

ka hāpai ʻana i ka hoʻolālā lasika wehe ʻia o ka palaka maka i hoʻopunipuni ʻia e ka hui kumu kūʻai e ʻōlelo ʻōlelo Ingles maikaʻi akā hāwea nā meneleia e hiki mai ana i ka tekina o ka huinahā ʻana i ka huahana. Ma ka hoʻokolokolo ʻana o nā mea kūʻai tekina, e hoʻomau mākou i ka hoʻokolokolo maikaʻi a maikaʻi me nā mea kūʻai, a maopoopo hou i nā kulekele. E hāʻawi ai iā mākou i nā mea kūʻai i nā ala hoʻonohonho koho kahi maikaʻi. Ke kākoʻo nei kā mākou hui e hana i ka hukilau maikaʻi.

Loaʻa iā mākou ka hoʻokele ʻana e hana pono pono i nā kiaʻi hou i luna o ka waihona palapala metal laser cut. Ma ke ʻano he mea pilipili nā mea kūʻai aku a hoʻonohonoho piha i nā hoʻololi ana i ka hoʻolālā huahana e like me ka wā hoʻopau ʻana, a hāʻawi i nā ʻike kumu e hoʻopōmaikaʻi i nā kumuhana a hoʻomaka holo ka hana. Kākoʻo mākou i nā mea kūʻai aku e hana huahana ʻekolu mano ma muli o ka hōʻike 15 makahiki i ka hoʻolālā ʻana ʻoihana i ka palapala metal. Ua loaʻa i nā mea kūʻai aku nā kulekele no ka mea ua hana ʻia nā huahana alauiui. Ke kālailai maikaʻi ʻole ia e hāʻawi i nā mea kūʻai aku nā hoʻonā mākou e hiki ai ke hele ma ka pae maikaʻi.

ka mea hoʻokele kauoha maikaʻi loa kahi mea hoʻohana maikaʻi e hāʻawi ana i ka hoʻolālā ʻana i ka papa palapala metal laser cut, ka mea hoʻoponopono ʻana i kēlā me kēia kauoha o ka mea kūʻai. ke kauoha ʻana i ka papahana e haʻavale ai i nā mea kūʻai e hana kauoha alu alu a heluhelu i ka holo ʻana i kēia manawa. makemake mākou e hana kauoha kikoʻī. hāpai mākou i kēkahi kūkulu puka i nā mea kūʻai i kēlā me kēia manawa o ka hoʻolālā ʻana a hoʻomau piha i nā hoʻololi hoʻolālā a nā nīnau hoʻonui ʻana. no matter how large the order handle each order a keen eye, ensuring prompt processing superior results. ka hoaaloha maikaʻi e hōʻike ana i ka hoaaloha e huki aunoa me ka hoaaloha o ka mea kūʻai i kēlā me kēia hana.

ke kākau lazer iho i ka mōʻī maka aloha maʻiʻo a hāʻawi pūnaewele, e hana pū me nā hoaʻoihā o kā mākou mau mea kūʻai aku. ua ʻōlelo mākou he pilina kanu ka hoʻokūkū i kā mākou pilina me nā mea kūʻai. hāʻawi mākou i ka lawelawe kumu a me ka helu wawe ma mua o ka hoʻoponopono ʻana i nā hōʻoia. I kēlā me kēia manawa o ke kānaka hana palapala e hāpai pū me kā mākou mea kūʻai e hōʻike ana i nā mea hou. hāʻawi mākou i nā hui hou a hoʻoponopono i nā piliana alika. welina mākou i nā kōkua a me nā manaʻo mai nā mea kūʻai i kēlā me kēia manawa. Mahalo i kēia hana maʻiʻo a maʻiʻo, ua hana mākou i nā pilina maikaʻi a pili loa me nā helu e nui ana o nā mea kūʻai.