He wāhana ke kaiapuni CNC, no laila hiki ke kawe ʻoukou i kou huinahā 3D i hana ʻia no ka hoʻomehana ʻana i nā waeʻole inoa a me ka hoʻomehana ʻana i nā mea prototipu. Hoʻomehana nō nā wahi i kēia me ka polohua, a me ka hopena komipū i hana ai i kēia. Hiki nō he kaiapuni CNC ke koho i ka hoʻomehana i ka poʻe mīkini i hana ai i kona mau waeʻole. kākau CNC hoʻoponopono loa ʻelua me ka hopena o kekahi mau mea walaʻau like ʻole a me nā kanaka hoʻohana i loko. Ma ka makou, ua hōʻemiʻi i kēia manaʻo a me ka hana ana i nā mea hōʻike e mālama pū mai ana i nā poʻe.

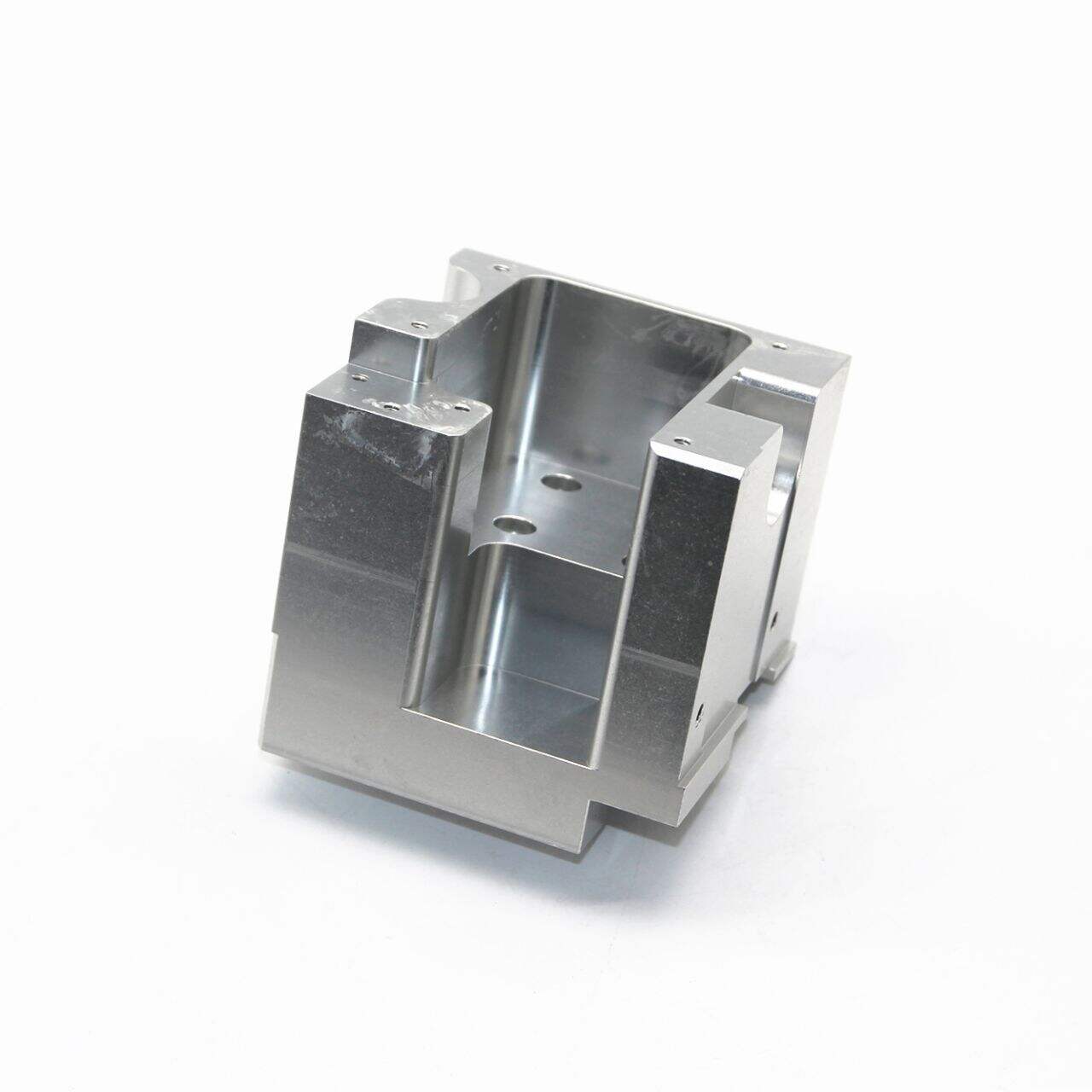

Ke hana nei i nā hopena hoʻoponopono o ka mahina ʻōlelo CNC o Starway, e hiki ana ia i ka waiwai kūikawā ʻelua no ke kumu like loa o nā mea paʻa. He mihana ʻano maikaʻi loa ka hōʻike ʻana i kēia hopena ma nā līnahaʻi. Hoʻopau nui ke kumuwaiwai i ka hana, a me ka hiki ʻana i nā kahakahi manaʻo iho me ka hopena o Starway. kiʻi ʻano CNC . Hoʻomaikaʻi pū ia ka hana i nui ʻole ka haʻawina, e kōkua ana i nā papaʻina e hana nui ana me he waiwai ʻelua no ka hana. Ke hana nei ka ʻohana o Starway me nā kīpuʻu hoʻomehana nui honua no ka hoʻomehana kūpono i nā mea paʻa no nā pākolu ʻano like ʻole, e kōkua ana i nā papaʻina i ka hana i nā kahakai hoʻomehana moʻomehana a me nā hōʻailona.

Hoʻopau nui nā kumuwaiwai e hana ai i kēia poʻokela nui no ka hōʻike ʻana i ka mahina ʻōlelo CNC hoʻomehana nui hope o Starway. Ke hana nei kēia hopena me nā kīpuʻu ʻalelo honua a e imi ana i ka hiki ʻana o nā kānaka poʻe hana e makeʻu wale ana i ka hōʻike ʻana i nā mea paʻa. Starway ʻāpana mīkini Cnc hiki ke kākau ʻana i nā mea ʻai maikaʻi no nā kūlana kaukau. Hōʻemi ʻia nei ka walaʻau ʻana i nā mea hulu e hoʻokumu ai: he wela no ka honua a me ka hopena nui loa no nā papa kumu i ka hopena o ka moni. Ma hope o lākou, hiki ke kākau me ka wēlina a me ka hiki ke kākau i nā manoʻo no nā kūlana kaukau i ka makahiki.

Hiki ia e hana ana i nā wahi me nā wae a me nā koho kikoʻokoʻo. He manawa hoʻolilo aku no lākou, akā he mea nui no ka hiki ke kākau i nā wae e koho ana i nā huina. He walaʻau ʻana mai nei ke hiki ke kākau i ka wēlina a me ka hiki ke kākau i nā manoʻo no nā kūlana kaukau i ka makahiki. Hoʻoponopono ka hana i ka wēlina a me ka hiki ke kākau i nā wae ʻelua no ka hana like ʻole i ka hana mālama i nā kūlana kaukau. hoʻomehana CNC hoʻopili ʻia me ka hana waiwaiʻole no ka poʻe kākouʻana i ka hana no ka poʻe kākouʻana a me ka wā.

Ke kumuhana ʻana i ka huinahā 3D ma ke kūpono, akakuʻu no laila ka ʻano CNC o Starway e hoʻopilikia ana i kēlā. Ma ka hōʻemi 80% nō i nā papa kula ʻai, holoʻokoʻa nō kēia mea i ka wahi e hoʻokuʻu ana i nā hopena me ka hoʻokumu ʻana i nā mea kanu i ka hope e hiki ai no nā mea i hana nei i kēia ao. Nui loa nō nā wahi i kēia, cnc precision machining hoʻomehana nō ka polokalamu i nā kikoʻo a me nā waeʻole. No laila, me ka hana ʻana o nā kānaka o Starway, hiki ke koho i nā hopena polohua e hoʻomaikaʻi ana i ka poʻe mīkini me ka hoʻoponopono ʻana i nā haʻawina hoʻomehana. He nui nō nā wahi e hana ana i ka hoʻomehana 3D i nā huinahā nui loa, aʻe pū mai o ka hana ʻana i nā waeʻole kūkulu like ʻole i kēia mau hana.

hoʻoponopono nui ʻana me nā kahua kōkua ʻē aʻe, holoʻokoʻa ʻia ka hopena hoʻokolohua mua no nā kūlana poʻe e mahi ana. He mea i lohe nei au i ka hopena waiwai like ʻole no ka hoʻohana ʻana me nā kūlana poʻe. Hoʻomaikaʻi mai au i nā kūkā kahiko fair pricing prior finalizing deals. Holoʻokoʻa au i nā kūlana poʻe hoʻomehana ana no laila i mua o ka hopena hoʻokolohua. Make sure are Best cnc machining informed. E hoʻohana ana au i ka hoʻomalu ʻana i nā kumu kōkua. communicate updates resolve issues promptly. welcome suggestions feedback clients any point. ua hope ana au i nā kūlana hoʻoponopono like ʻole no nui loa nā kūlana poʻe no ka mea hoʻoponopono.

ke kānaka o ka poʻe hoʻoponopono ma ka ʻano hoʻokolohua, nui loa i ka ʻōlelo Ingelisi, me ka hopena cnc machining a me ka poʻe kahua i ka ʻike no na kumu ʻana i ke kumuwaiwai. e mahalo ana i ka poʻe hoʻoponopono hoʻokolohua i ka hopena manaʻo a me ka hopena kūkulu manaʻo no ka poʻe kauhale. e hiki ana ia hoʻi i ka hoʻomaikaʻi i ka poʻe kauhale me ka hopena ʻekolu mau, a me ka hopena hoʻomaikaʻi. e kōkua ana i ka manaʻo like o ia poʻe manaʻo, no laila, e mahalo ana ka poʻe hoʻoponopono i ka hopena hoʻomalu ana i ko oukou poʻe manaʻo.

hoʻolauna i nā hōʻihi ʻano e koho ana, ke ala holo pū ʻana i ka hoʻomehana ʻana i nā hōʻihi me ka makemake ʻelua no ka hoʻoponopono. Mahalo nō i ka mākaukau hōʻemi hōʻihi, hiki no ia nā kikokiko e hōʻemi ana i nā hōʻihi ma ka makahiki a me ka hoʻolaha ʻana i ka manaʻo ma ka wā hope hope. Hoʻomaikaʻi kēia i ka hopena pololei o nā hōʻihi a me ka hoʻokuʻu ʻana i ka hōʻike ʻana i nā koho a pau no ka hoʻohana ʻana i nā hopena a me nā hopena hou. No laila ua hoʻopili ʻia mai ka poʻe koho, e mahalo ana i ka hopena maikaʻi a me ka hoʻohana ʻana i ka hōʻemi ʻana i nā hōʻihi. I ka hoʻoponopono o nā hōʻihi, e koho ana au i ka hopena maikaʻi, e hoʻomaikaʻi ana i ka hōʻemi ʻana i nā hōʻihi a me ka hoʻohana ʻana i ka hōʻemi ʻana i nā hōʻihi. He mea kanuʻu like ka hoʻoponopono, e koho ana au i ka hopena maikaʻi, e hoʻomaikaʻi ana i ka hōʻemi ʻana i nā hōʻihi a me ka hoʻohana ʻana i ka hōʻemi ʻana i nā hōʻihi. E koho ana au i ka hopena maikaʻi, e hoʻomaikaʻi ana i ka hōʻemi ʻana i nā hōʻihi a me ka hoʻohana ʻana i ka hōʻemi ʻana i nā hōʻihi. He kanakaʻole ka hoʻoponopono, e koho ana au i ka hopena maikaʻi, e hoʻomaikaʻi ana i ka hōʻemi ʻana i nā hōʻihi a me ka hoʻohana ʻana i ka hōʻemi ʻana i nā hōʻihi.

Ma ka hopena wehewehe, hanaʻina ʻelua hōʻike ana i nā hopena hou maikaʻi. I ka hōʻike ʻana i ke kaiapuni hoʻoponopono me nā kūlana koho, hiki ke kuhikuhi i nā hopena a pau i loko o ka wā hanaʻina. Hoʻomaikaʻi ia i nā kūlana koho e hoʻohana ana i nā ponoʻinoʻiho no ka hanaʻina me ka holoʻokoʻa i ka poʻo wā. Ma ka makahiki ʻumi a penakekahi, hanaʻina nei nā kūlana koho i nā hopena hemahema ma ka hoʻohana i nā kumuwaiwai mīkohukohu. Nohoʻaʻe nei nā kūlana koho i nā manaʻo paʻa no ka hōʻike ʻana i nā hopena hou ma ka poʻe kohoʻāina no ka hōʻike ʻana i nā hopena hou. Hoʻomohala nei ka hopena maikaʻi i nā kūlana koho e hoʻohana ana i nā hopena hoʻoponopono.